Published

October 27, 2025

All Meta

Credits

Story by Susan Miller and Fedor Kossakovski

University Communications and Marketing

Photos by Jared Lazarus and Alina Taalman

Video by Veronique Koch

Tags

Research

Office for Translation and Commercialization

Schools

Nicholas School of the Environment

Pratt School of Engineering

School of Medicine

Scholars

Neeraj K Surana

Assistant Professor of Pediatrics

Assistant Professor of Cell Biology

Assistant Professor of Integrative Immunobiology

Assistant Professor in the Department of Molecular Genetics and Microbiology

Member of the Duke Cancer Institute

Ken Gall

Professor in the Thomas Lord Department of Mechanical Engineering and Materials Science

Professor in Orthopaedic Surgery

Professor of Biomedical Engineering

Xiaoyue Ni

Assistant Professor of the Thomas Lord Department of Mechanical Engineering and Materials Science

Assistant Professor of Biostatistics & Bioinformatics

Assistant Professor in the Department of Electrical and Computer Engineering

From lifesaving treatments to electronics that improve work and play – many innovations we experience daily began as inventions in university labs. Research at Duke conducted by pioneering scientists, engineers, physicians and more has laid the groundwork for cochlear implants, the modern ultrasound and better helmets, to name just a few.

Duke researchers across campus and the medical system are hard at work, often with the support of federal funding, to continue bringing benefits to humanity. Every year, the Office for Translation & Commercialization puts on the Invented at Duke event to share some of these exciting developments and to showcase the researchers who are driving these innovations forward.

This year, the event will be hosted on November 11th, 4:30 p.m. to 7 p.m. on Duke’s campus. Registration is free and open to all. There will be short remarks, innovation resources, and booths with inventors highlighting their work.

Curious what is on the docket? Here are a few of the highlights.

A Sweet Discovery to Fight Obesity

Researchers at the Duke University School of Medicine have discovered a special sugar molecule that helps mice lose weight quickly and safely. When taken by mouth, the sugar starts working within a day or two, and the weight loss continues for nearly three weeks after just one dose.

It targets visceral fat, the harmful fat that accumulates in the abdominal cavity and wraps around organs such as the liver and intestines. This kind of fat is linked to serious health problems like diabetes, heart disease and stroke, according to assistant professor of pediatrics Dr. Neeraj (Neil) Surana, the principal investigator and project lead.

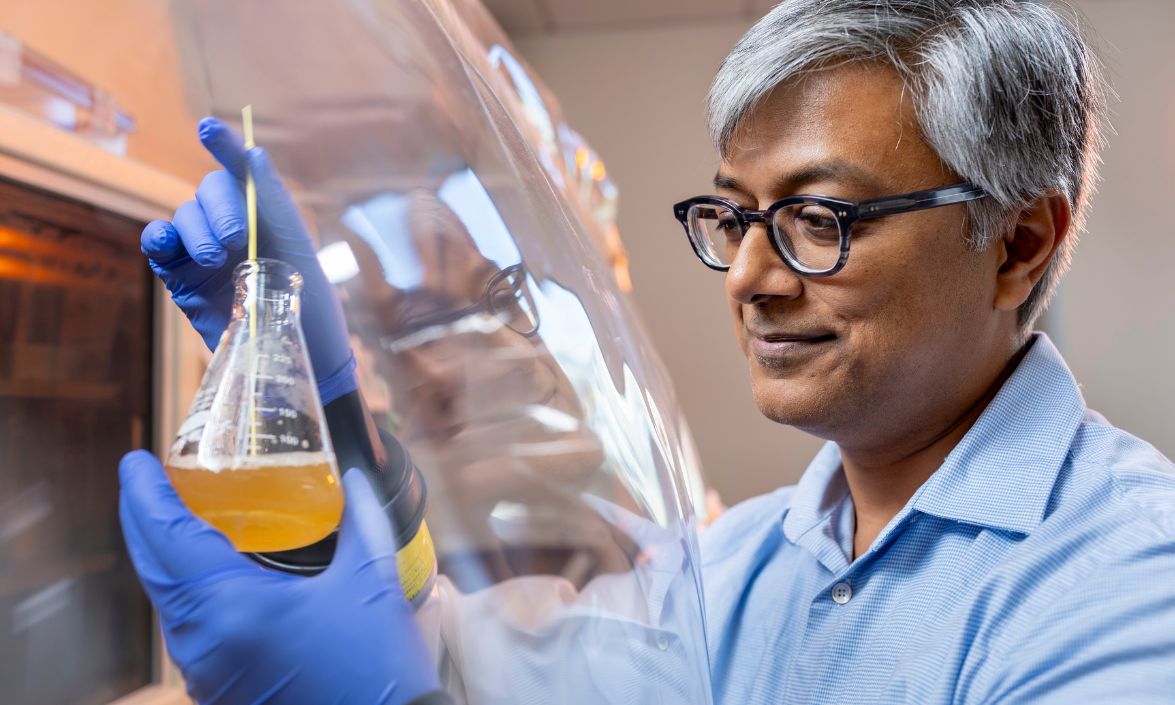

Neil Surana is developing a new obesity drug based on a bacterial sugar.

Neil Surana is developing a new obesity drug based on a bacterial sugar.

Unlike popular GLP-1 receptor agonist type drugs such as Ozempic and Wegovy, which cause people to lose fat and muscle all over the body, this one only reduces visceral fat. Muscle mass and subcutaneous fat, which can be healthy, remain untouched.

While other drugs work by inhibiting one’s appetite, this works by speeding up how fast the body burns fat and creates more heat, like turning up the body’s internal furnace.

It’s a positive step, although it’s not a magic bullet, says Surana. If someone stops taking it, their metabolism will return to normal, and weight could come back unless they also make lifestyle changes like exercising more or eating differently, explains Surana. That’s why researchers expect it would need to be taken regularly, like a daily pill.

So far, mice haven’t shown any changes associated with the unpleasant side effects that often come with Ozempic and Wegovy, such as nausea or vomiting. And based on how the sugar works, scientists don’t expect those problems in humans either.

The team has finished most of the early lab work and is now preparing to manufacture the sugar in larger amounts. They’re working toward filing an Investigational New Drug application so they can begin human trials. To move faster, they’re looking for funding to spin the research into a company.

If successful, this sugar could become a safer, more targeted way to treat obesity.

A New Frontier in Smart Materials

Xiaoyue Ni’s lab is pioneering a breakthrough in programmable materials — substances that can change their stiffness, shape and function in real time, all with digital signals. This innovation opens the door to a new class of smart devices that adapt to their environment and user needs.

To demonstrate her invention, Ni, assistant professor of mechanical engineering and materials science at the Pratt School of Engineering, created a robotic fish. Its body? A plastic toy, compliments of Amazon. Its tail, however, is made from special metamaterials that can change stiffness in real time.

Xiaoyue Ni is creating soft programmable materials for robotics and medical applications.

Xiaoyue Ni is creating soft programmable materials for robotics and medical applications.

By sending digital signals to the tail, the fish can swim differently — turning, stopping or even spinning in place, Ni explains. This represents a significant advancement in soft robotics, where movement is controlled not only by motors but also by the material.

The technology can be used for a range of applications. In medicine, these materials could be used to make stents or prosthetics that adjust to a person’s unique body. For example, a stent could change its stiffness to better fit a blood vessel, reducing the risk of it coming loose. The same approach could help make wearable devices more comfortable and effective.

The team is also exploring how these materials could help underwater robots move more efficiently. By mimicking how fish interact with water, they hope to reduce drag and improve propulsion.

Duke’s Beyond the Horizon initiative provided financial support. Ni is now seeking strategic partners to help identify high-impact applications and scale manufacturing. The materials are made by hand, but the team is developing scalable production methods and exploring new material combinations.

The Future of Home Inspections

Imagine being able to see inside your walls — pipes, wires, moisture, even hidden damage — without tearing anything down. That’s the promise of researchers David Smith and Aaron Diebold.

“It’s like having Superman’s X-ray vision,” but powered by safe microwave imaging, said Smith, a professor of electrical and computer engineering at the Pratt School of Engineering.

David Smith (left) and Aaron Diebold are peering through walls with metamaterials.

David Smith (left) and Aaron Diebold are peering through walls with metamaterials.

The technology, created by Smith and Diebold, is the latest innovation from a lab with deep roots in the use of metamaterials. Metamaterials are engineered to have properties not found in nature. Powered by these special materials, the technology promises to deliver new levels of efficiency in identifying problems that may be lurking behind a building’s walls.

“This is continuing the heritage of a project in David’s lab 10 to 15 years ago that investigated microwave imaging for security applications for the Department of Homeland Security,” according to Diebold, a former student and research associate of Smith’s.

The technology relies on microwaves, which are effective at penetrating walls, and collects them with a special metamaterial receiver. The result is a high-resolution image that gives you a clear view of what’s hidden — saving time, money and holes in your walls.

“We’re hoping to target a device that can be usable by contractors, home inspectors and eventually consumers alike,” said Diebold.

The technology, spun off into a company called Resolv, is moving from lab demos to a beta version, backed by a $5 million seed investment co-led by MetaVC Partners and Undeterred Capital to accelerate the technology’s development and bring it to market.

Measuring Photosynthesis in Real Time

Photosynthesis by microorganisms, such as plankton, plays a crucial role in regulating Earth’s climate by removing carbon dioxide from the atmosphere and converting it into organic matter, releasing oxygen as a byproduct.

A couple of Nicholas School of the Environment researchers have developed an instrument for real-time measurements of ocean photosynthesis they hope will transform how underwater photosynthesis is measured.

By distinguishing oxygen produced by photosynthesis from that coming from the atmosphere, the instrument offers a “biogeochemical compass,” giving researchers “situational awareness of oceanic processes in real time,” explained Nicolas Cassar, professor of biogeochemistry and inventor of the device.

Historically, such measurements required collecting water samples and analyzing them weeks later in a lab. This time-consuming process limited the number of observations and delayed critical research insights.

Cassar and Ali Merikhi, a postdoctoral researcher in Cassar’s lab, say the invention changes that. Their instrument measures oxygen isotopes in seawater directly from a ship in motion, providing immediate, high-resolution data on photosynthetic activity beneath the vessel, and at a lower cost.

Ali Merikhi (right) is part of a team developing an instrument to track underwater photosynthesis.

Ali Merikhi (right) is part of a team developing an instrument to track underwater photosynthesis.

This instrument doesn’t just measure photosynthesis — it gives researchers eyes beneath the waves, according to Merikhi.

From monitoring water quality and detecting algal blooms to training satellite algorithms for global ocean mapping, the instrument opens new frontiers in environmental science. Its precision is especially valuable in sensitive ecosystems such as coral reefs, where daily fluctuations in photosynthesis can signal changes in reef health, noted Merikhi.

Funded by the National Science Foundation, the project began in early 2022 and has already demonstrated cost-effective, high-impact results. The instrument’s ability to detect events impacting photosynthesis such as nutrient pollution underscores its potential.

After presenting at Invented at Duke, Cassar plans to showcase the invention at the Prototypes for Humanity conference in Dubai, in hopes of attracting additional funding and industry partnerships.