Australia is continuing to drive forward its ambition for nuclear-powered submarines (SSN). The first day of Indo-Pacific 2025, held in Sydney from 4-6 November, was marked by a flurry of announcements relating to submarines.

Australia is continuing to drive forward its ambition for nuclear-powered submarines (SSN). Nor is this an endeavour for the fainthearted, as one defence industry executive remarked, “Once you’re in, you’re in. We have to keep going about that every single day in order to make sure we deliver that capability.”

The first day of Indo-Pacific 2025, held in Sydney from 4-6 November, was marked by a flurry of announcements. For example, the Department of Defence revealed a new strategic agreement paving the way for South Australian firm PMB Defence to supply batteries for AUKUS submarines.

PMB Defence is partnering with BAE Systems in the UK to “enable the potential integration of its advanced nickel zinc battery system into the design of the future conventionally armed, nuclear-powered submarines”. This covers both Australian and British SSN-AUKUS submarines.

Contracts between BAE Systems and PMB Defence are valued in excess of A$34 million (US$22 million). PMB Defence already supplies the main storage batteries for Australian Collins-class submarines.

The SSN-AUKUS is being developed trilaterally. It is based on the UK’s next-generation design that incorporates technology from all three nations, including propulsion plant systems and components, a common vertical launch system and conventional weapons. They will also have a common combat management system.

At Indo-Pacific 2025, Lockheed Martin was highlighting its pedigree in developing and modernising combat management systems (CMS). Lockheed Martin’s CMS is employed on US Navy (USN) Virginia-class SSNs, and that means they will be present on the second-hand boats that Australia receives from the USN.

David G. Schappert, Undersea Systems Business Development Principal at Lockheed Martin Rotary and Mission Systems, told Naval News that Lockheed Martin Australia has the expertise to sustain the complex CMS for Australia’s Virginia-class boats, and he hopes that Australia will avail itself of this opportunity.

Lockheed Martin Australia had earlier been appointed CMS developer for Australia’s aborted Attack-class submarines being acquired from Naval Group.

Local involvement

Both HII and Babcock have transferred staff to Australia to populate H&B Defence, a joint venture created in June 2024. H&B Defence subsequently issued an expression of interest in Australia for involvement in the nuclear-powered submarine enterprise, to which 378 companies responded.

On 4 November, a group of Australian businesses was successfully validated against HHI’s Newport News Shipbuilding (NNS) division standards. These suppliers were benchmarked through H&B Defence’s Australian Submarine Supplier Qualification (AUSSQ) programme. This move is significant because it paves the way for these companies to be formally qualified into the US nuclear submarine enterprise.

The companies certified are CQMS, AW Bell, AJAX, Hycast, Intercast, Supashock, Camco, Stella, Ferra, Axiom and Marand. Once other uplift activities are completed, they can join the NNS supply chain alongside eight other Australian suppliers that have already achieved this status. Three have already received formal requests for quotation from NNS to supply to the USA.

HII stated, “Led by the Australian Submarine Agency and delivered by H&B Defence, the AUSSQ programme has rapidly matured into a proven and effective model for preparing Australian businesses to compete in one of the world’s most demanding defence supply chains.”

Michael Lempke, H&B Defence Board Chair, said: “The AUSSQ programme is delivering real capability, real opportunity and real momentum to position Australian businesses for AUKUS export opportunities in the US.”

Unmanned cooperation

The US Navy has already demonstrated the ability to launch and recover a REMUS UUV from a Virginia-class submarine. (Credit: Gordon Arthur)

Regarding US submarine construction, Eric Chewning, HII’s Executive Vice President, Maritime Systems & Corporate Strategy, said, “We’ve increased our throughput across our shipyards by 15%. We’re continuing to hit that acceleration. One of the important strategies we have to do that is the distributed shipbuilding model where we’re outsourcing.” Indeed, the bottleneck in US production can perhaps be allayed by help from Australian suppliers.

Unmanned systems is another rich area of cooperation between HII and Babcock. In September this year, the two signed a memorandum of understanding to extend collaboration to integrate HII’s REMUS unmanned underwater vehicles (UUV) and Babcock’s weapon handling and launch system.

Indeed, HII announced on 6 October this year that the USN had demonstrated the launch and recovery of a REMUS 620 autonomous underwater vehicle from a Virginia-class SSN. The Royal Navy expects to do a similar trial in 2026 using Babcock’s modified weapon handling system.

Nick Hine, Chief Executive, Marine at Babcock, commented, “There are AUKUS opportunities if everybody wants to take them of having a single underwater vehicle operating between three nations.” The same system could also be used on the Collins class to launch UUVs.

Such technologies are an important part of AUKUS Pillar 2. Chewning said, “Where you start to really see the benefit of the trilateral cooperation is in that AUKUS Pillar 2 we’re really limited in some part only by our imagination, As we start to think about what do I wrap around the submarine itself, which is already the premier apex predator in the ocean, to make it even deadlier and more capable?”

Interestingly, South Korean KSS-III submarines also use Babcock’s weapon handling system, so this capability is relevant to the Republic of Korea Navy as well.

Powerplants

Rolls-Royce has powered Royal Navy nuclear submarines for 65+ years, and it is expanding its Derby site to support the Australian and British submarine programmes. Interestingly, it is the only private company in the world “with the nuclear capability to manage reactor design, manufacture and decommissioning within one single entity,” it said.

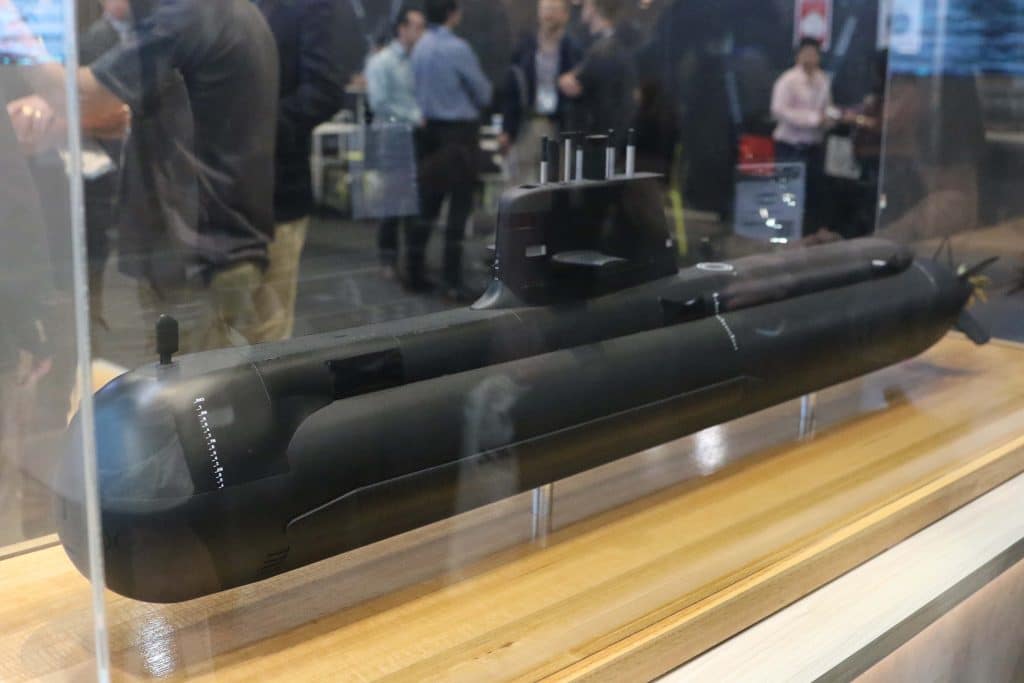

This is an accurate depiction of what the SSN-AUKUS will look like, as displayed by Rolls-Royce with a London bus alongside to give scale.

Steve Carlier, Rolls-Royce Submarines President, told Naval News that Rolls-Royce received confirmation in May 2023 that it would provide all the nuclear reactor plants for SSN-AUKUS boats. These will be third-generation PWR3+ nuclear reactors, an upgrade of the PWR3 already utilised in the Dreadnought class of the Royal Navy.

Carlier said the PWR3+ will provide greater operational flexibility, giving crews more options in how to use the energy. For example, they can use the ship’s own power to supply the submarine when docked, instead of having to rely on a shore-based supply. It also brings greater safety levels, including under faulty conditions, and these reactors last the 30+-year lifespan of each submarine.

“Nuclear submarines bring unsurpassed endurance, range, stealth, power and reliability that still provide the absolute pinnacle of military advantage,” Carlier said. The SSN-AUKUS type’s preliminary design review is expected to be reached in September 2026.

The components of the reactors will be manufactured in the UK before being shipped to Australia to be installed at the Osborne Shipyard.

Ageing backstop

The Royal Australian Navy is extending the life of six Collins-class submarines. (Credit: Gordon Arthur)

Undoubtedly, Australia’s SSN dreams are replete with risk. This means the Royal Australian Navy must cover itself, and this is reflected in Defence issuing a contract extension to Raytheon Australia for sustainment of the combat systems in the country’s six Collins-class submarines. Announced on 4 November, the 3year-and-nine-month contract extension is worth A$277 million (US$180 million).

Raytheon Australia stated, “Core elements of the combat system management framework contract include combat system integration and manager services, architecture and design, upgrades and updates, implementation and coordination of the AN/BYG-1 system, wharf-side and deployable technical support, and procurement, warehousing and freight services.”

The first Collins-class submarine is expected to enter a life-of-type extension (LOTE) programme next year, which will extend the life of each boat by ten years. Each LOTE will take two years to complete, and it will occur when each submarine is due for its full cycle docking.