MIT researchers have developed a new “self-assembling” battery material for electric vehicle (EV) battery recycling.

Currently, many used EV batteries end up in landfills because recycling is complex and expensive, and often uses harsh chemicals.

MIT’s new approach is based on a “recycle-first” mindset.

Instead of designing a battery for performance and then figuring out how to recycle it later, the team has designed a key battery component to be easily recyclable from the beginning.

This battery material works as the electrolyte—the part of the battery that shuttles lithium ions between the positively charged cathode and the negatively charged anode.

But what makes it so special is that it can quickly break apart when submerged in a simple organic liquid.

“The electrolyte holds the two battery electrodes together and provides the lithium-ion pathways,” said Yukio Cho, the paper’s first author.

“So, when you want to recycle the battery, the entire electrolyte layer can fall off naturally, and you can recycle the electrodes separately,” Cho added.

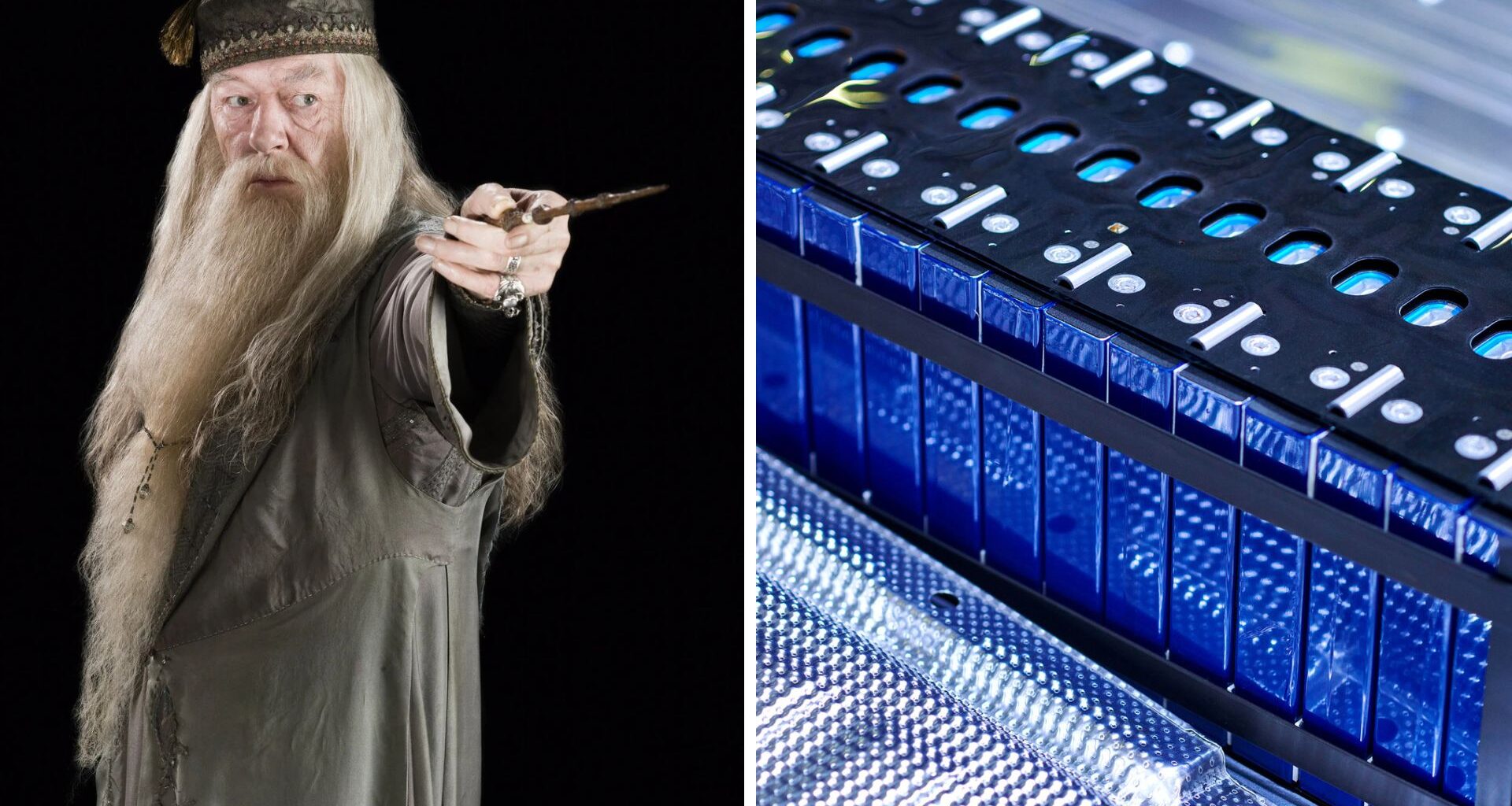

Battery tech inspired by Harry Potter magic trick

Inspired by a scene in “Harry Potter” where Dumbledore cleans a room with a flick of his wrist, researcher Cho wondered if a similar “magic” could be applied to battery recycling.

When Cho learned about molecules that can assemble into complex structures and revert to their original form, he envisioned using this concept to create recyclable battery material.

The sustainable electrolyte material comprises tiny molecules called aramid amphiphiles (AAs) that can self-assemble in water.

These molecules were designed to mimic the strong, stable chemical structure of Kevlar, a bulletproof material.

Moreover, polyethylene glycol (PEG) was added to the molecules to enable them to conduct lithium ions.

When exposed to water, the molecules spontaneously form durable nanoribbons with ion-conducting surfaces. These nanoribbons can then be hot-pressed to form a solid-state material.

“The material is composed of two parts,” Cho said.

“The first part is this flexible chain that gives us a nest, or host, for lithium ions to jump around,” Cho explained.

“The second part is this strong organic material component that is used in Kevlar, which is a bulletproof material. Those make the whole structure stable.”

Proof-of-concept

When the battery is no longer useful, it’s placed in organic solvents.

This liquid causes the electrolyte, which holds the battery’s layers together, to dissolve—much like cotton candy in water.

As the electrolyte breaks down, the entire battery disassembles, allowing its individual components to be easily sorted and recycled.

The team’s new material proved strong and tough enough to withstand the rigors of a working battery.

However, while the nanoribbons successfully moved lithium ions between the cathode and anode, a side effect called polarization slowed down the movement of ions during fast charging and discharging.

“The lithium ions moved along the nanofiber all right, but getting the lithium ion from the nanofibers to the metal oxide seems to be the most sluggish point of the process,” Cho explained.

This ultimately limited its performance when compared to today’s best commercial batteries.

The development is still a proof of concept, and the team plans to conduct more experiments to optimize the material’s performance.

If adopted, this technology could help bring lithium supplies back to the US by enabling the reuse of materials from existing batteries.

The researchers state that this material could be easier to adopt for new battery technologies that emerge in the next 5 to 10 years.

The findings were published in Nature Chemistry.