Since Christiaan Huygens paired a balance wheel and spiral spring in 1675, the hairspring has been the beating heart of every mechanical watch. Its material has always dictated chronometric performance. Steel, used for centuries, suffered from magnetism and temperature drift. Special alloys developed in the 20th century improved reliability – from Elinvar to Nivarox/Nivachron, made by the Swatch Group, and Parachrom by Rolex, among others. The late 1990s saw silicon adopted for its amagnetic and lightweight properties. Yet silicon is brittle and requires outside suppliers. The next step, conceived and executed entirely in-house by TAG Heuer, is the TH-Carbonspring, a technology that you might be familiar with already, but that’s back in 2025 and said to now be ready for commercial production.

Work began nearly ten years ago at TAG Heuer’s dedicated LAB (then Research Institute) to create a spring that combined the best properties of past materials while avoiding their compromises. Early try-outs appeared in 2019 with the Carrera Heuer 02T Nanograph tourbillon, which demonstrated the spring’s resilience and precision in a complication. The same year, TAG Heuer attempted to scale the idea with the Autavia Isograph Chronometer, equipping Sellita-based Calibre 5 movements with carbon hairsprings, but production challenges necessitated a return to traditional springs. Still, the experiment well demonstrated TAG Heuer’s intentions, which were to find an alternative to silicon, which is still protected by patents shared by Swatch Group, Rolex, Patek Philippe and Ulysse Nardin.

An evolution arrived with the Carbon Monaco for Only Watch (2021), where a Heuer 02 chronograph was fitted with a refined carbon hairspring, thus confirming its maturity and long-term stability. These experiments contributed to the fully industrialised TH-Carbonspring, now ready for serial production.

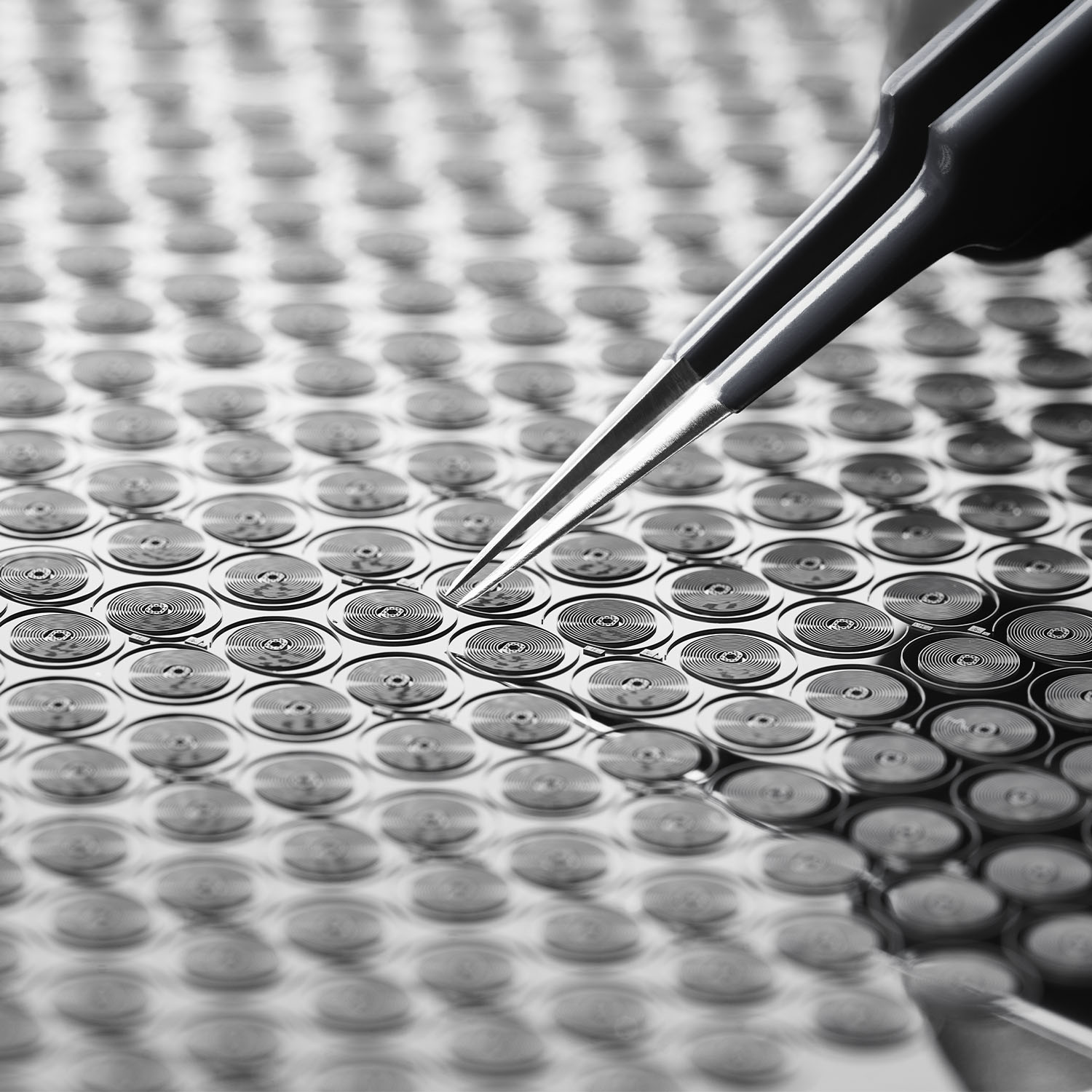

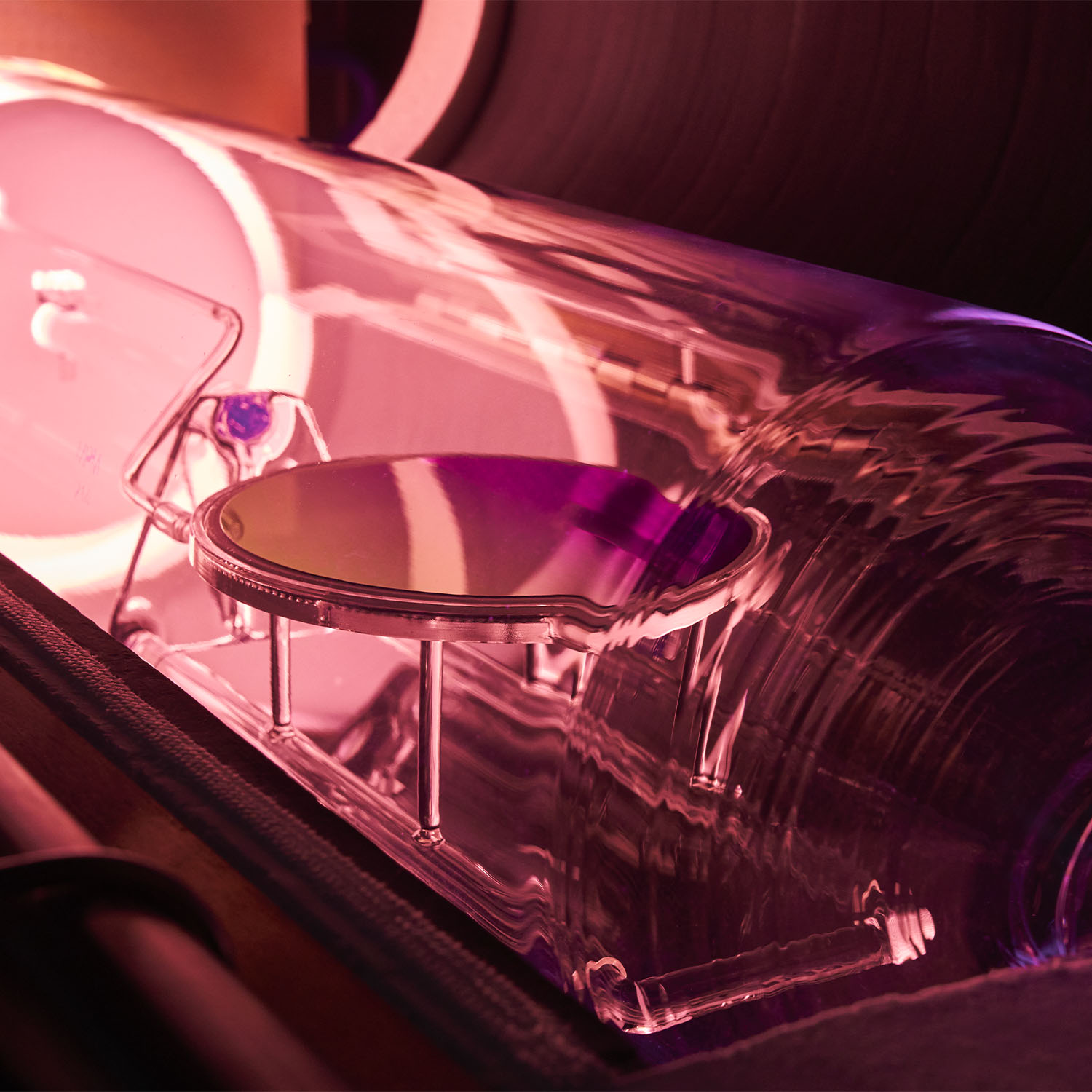

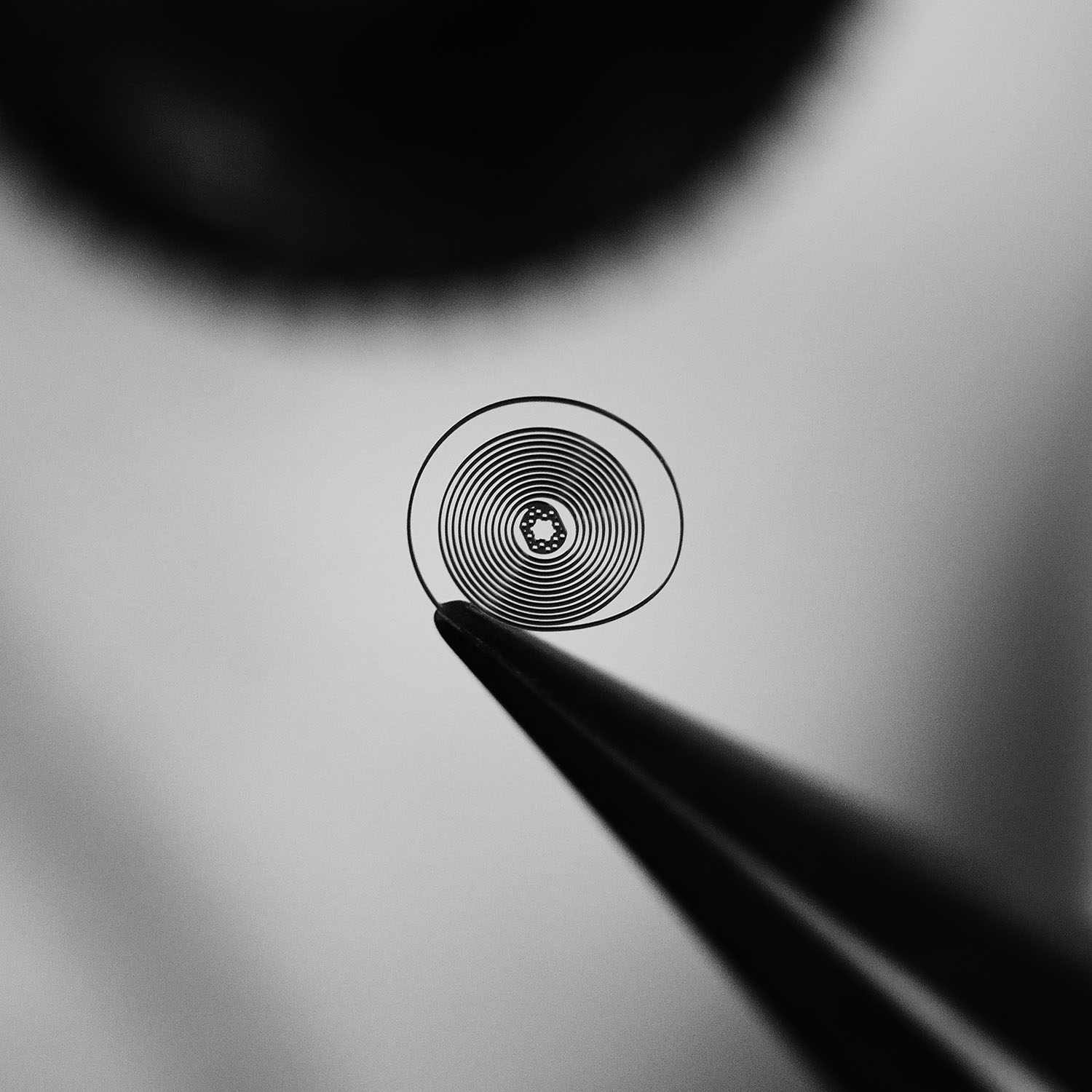

Unlike metal or silicon, the TH-Carbonspring is grown using a Chemical Vapour Deposition (CVD) process. Carbon nanotubes are cultivated in a controlled environment, then infiltrated with amorphous carbon to stabilise the structure. This produces a homogenous spiral of extremely low density. Critically, the collet, the tiny component that attaches the spring to the balance staff, is formed directly during growth, eliminating a separate and error-prone assembly step. Each batch undergoes refinement of layer thickness, geometry, and heat treatment to achieve concentric breathing of the spring. The result is a hairspring that can be produced consistently at scale, entirely within TAG Heuer’s own facilities, with four patents filed to protect the process. And this means that TAG Heuer doesn’t have to rely on patent-protected silicon to obtain almost identical benefits from a hairspring that’s made from carbon.

The TH-Carbonspring delivers three decisive upgrades over its predecessors. First, amagnetism: everyday magnetic fields no longer disturb the spring, eliminating a major source of rate deviation. Second, shock resistance. Reportedly, in laboratory testing, where steel bends and silicon fractures at impacts of up to 5,000 g, the carbon spring remains intact. Then, low mass: being lighter than silicon, it reduces inertia, improving isochronism and vertical-position stability. These factors result in more stable chronometry and less sensitivity to the environment. Finally, TAG Heuer has worked on reducing as much as possible the porosity of the material, which could be affected by humidity.

If the Carrera Nanograph proved the concept with a tourbillon regulator, the Autavia Isograph demonstrated its potential for mainstream calibres, though production at the time lagged behind ambition, and the concept had to be removed from stores. The Only Watch Carbon Monaco confirmed the technology’s maturity with a showcase of Heuer 02. Today, after all the failures and improvements, testing and refinement, TAG Heuer has validated the TH-Carbonspring for large-scale use, ensuring precision performance and warranty-grade durability. The technology is now offered within two iconic shapes: Monaco and Carrera.

TAG Heuer Monaco Flyback Chronograph TH-Carbonspring

To match the technical leap inside, the Monaco Flyback Chronograph TH-Carbonspring has been crafted almost entirely in forged carbon. The 39mm case, with a 14.1mm thickness, retains the bold geometry of the 1969 original but gains lightness and strength through the use of high-tech materials, featuring a crown at 3 o´clock and rectangular pushers also executed in carbon. The square sapphire caseback confirms the watch´s exceptional status, while its 100m water resistance keeps it practical.

The forged carbon dial is engraved with a spiral pattern that directly nods to the geometry of the hairspring, with three sub-registers arranged at 3, 6, and 9 o’clock. The running seconds indicator at 6 o´clock is nearly invisible, with a black gold hand devoid of any lume. Carbon indices, hour, minutes, and all chronograph hands are treated with white Super-LumiNova, providing crisp legibility, with a white chronograph seconds hand cutting across the dial.

The watch is powered by the new COSC-certified Calibre TH20-60, an automatic flyback chronograph with an extended 80-hour reserve, now regulated by the TH-Carbonspring oscillator. The watch is worn on a black rubber strap with textile embossing, closed with a DLC titanium folding clasp, completing a stealthy but unmistakably Monaco look. Only 50 pieces will be made, priced at CHF 17,000, and they will be available from December 2025.

Quick Facts: 39mm x 14.1mm – forged carbon case – domed sapphire front, sapphire back – 100m water resistance – forged carbon spiral-engraved dial – three sub-registers at 3, 6, 9 – black-gold hands and indices with Super-LumiNova – Calibre TH20-60 automatic flyback chronograph – COSC-certified – TH-Carbonspring oscillator – 28,800vph – 80h power reserve – black rubber strap with textile embossing – DLC titanium folding clasp – limited to 50 pcs – CHF 17,000.

TAG Heuer Carrera Chronograph Tourbillon Extreme Sport TH-Carbonspring

If the Monaco leans on pure design iconography, the Carrera Tourbillon Extreme Sport TH-Carbonspring doubles down on mechanical bravado. Housed in a 44mm forged carbon case with a tachymeter bezel in the same material, the watch combines the new oscillator with a flying tourbillon integrated into TAG Heuer’s latest chronograph calibre.

The black opaline registers at 3 and 9 o’clock keep the chronograph readout familiar, and the tourbillon at 6 o’clock is framed by a black-gold circlet and left exposed. Spiral engraving on the carbon dial again nods to the spring. Rhodium-plated indexes and faceted hands are treated with Super-LumiNova for clarity against the complex backdrop.

The Calibre TH20-61 features a column-wheel chronograph design, COSC certification, and a new carbon oscillator, offering a 65-hour power reserve. The water resistance is 100m, and a black rubber strap with a DLC titanium folding clasp keeps the watch secure. Limited to 50 pieces, the Carrera Tourbillon Extreme Sport TH-Carbonspring will be available at select TAG Heuer boutiques in early 2026, priced at CHF 40,000.

Quick Facts: 44mm x 15.4mm – forged carbon case – forged carbon tachymeter bezel – sapphire front, DLC titanium back – 100m water resistance – forged carbon dial with spiral engraving – sub-registers at 3 and 9, tourbillon at 6 – black-gold and rhodium-plated hands and indices with Super-LumiNova – Calibre TH20-61 automatic chronograph with flying tourbillon – COSC-certified – TH-Carbonspring oscillator – 28,800vph – 65h power reserve – black rubber strap – DLC titanium folding clasp – limited to 50 pcs – CHF 40,000.

More information can be found at www.tagheuer.com.

https://monochrome-watches.com/in-depth-return-of-the-tag-heuer-th-carbonspring-oscillator-carbon-hairspring-new-monaco-and-carrera-models-2025-review/