3D printing may be a breakthrough technology, but it isn’t sustainable. Most printers still rely on petroleum-based plastics, while greener alternatives are too brittle to use in parts that need strength.

That trade-off has left researchers searching for a way to make printing both eco-friendly and durable.

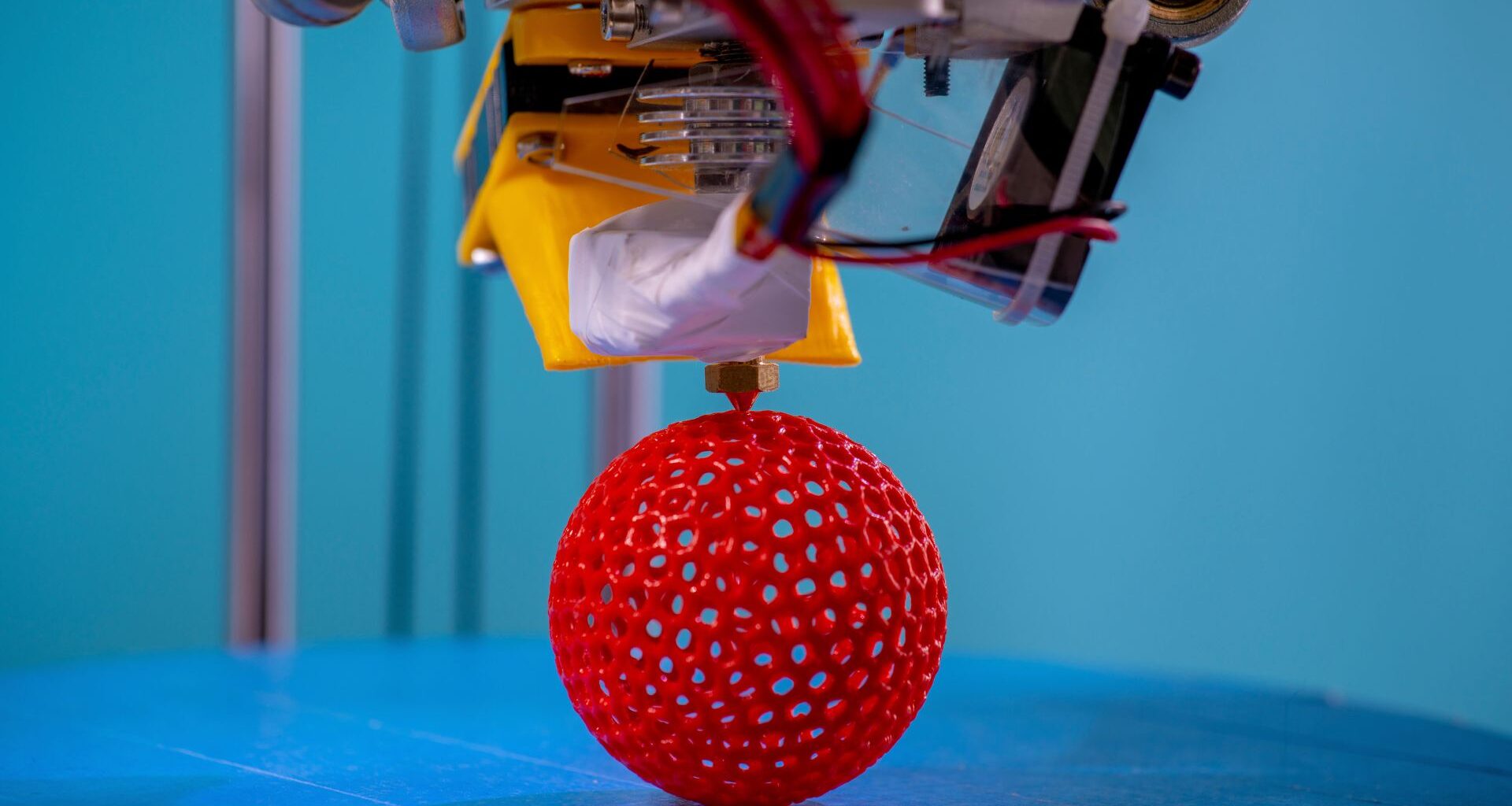

A team from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) and the Hasso Plattner Institute has unveiled a new system called SustainaPrint.

The toolkit combines software and hardware to strategically reinforce only the most stressed areas of a design with stronger filament while keeping the rest of the part eco-friendly.

The system runs simulations to predict where stress will build up in a 3D model, then reserves high-performance plastics for those regions. Everything else is printed with biodegradable or recycled filament, cutting plastic use without giving up structural performance.

“Our hope is that SustainaPrint can be used in industrial and distributed manufacturing settings one day, where local material stocks may vary in quality and composition,” says MIT PhD student Maxine Perroni-Scharf, a lead author of the project.

Testing the balance between strength and sustainability

For experiments, the team used Polymaker’s PolyTerra PLA as the eco-friendly filament and Ultimaker’s PLA for reinforcement.

Just 20 percent reinforcement was enough to recover up to 70 percent of the strength of a fully strong print.

The researchers printed dozens of objects—rings, beams, wall hooks, headphone stands, and plant pots—using three methods: all-eco, all-strong, and the hybrid SustainaPrint approach. Each was tested by pulling, bending, or snapping it to measure strength.

In several cases, the hybrid prints matched or exceeded the fully reinforced versions. In one test with a dome-shaped object, the hybrid version outperformed the all-strong print. “This indicates that in certain geometries and loading conditions, mixing materials strategically may actually outperform a single homogenous material,” Perroni-Scharf says.

Open-source and classroom-ready

SustainaPrint starts with a custom interface where users upload 3D models. A simulation maps where forces are most likely to act, highlighting zones for reinforcement.

To make the approach widely accessible, the team also built a low-cost DIY testing toolkit that uses 3D-printed modules with everyday items like pull-up bars or digital scales.

The software and toolkit will be released as open-source, making them freely available for modification and use.

The team also sees strong educational value. “In a classroom, SustainaPrint isn’t just a tool, it’s a way to teach students about material science, structural engineering, and sustainable design, all in one project,” Perroni-Scharf says.

Co-author Patrick Baudisch, professor at the Hasso Plattner Institute, adds: “The project addresses a key question: What is the point of collecting material for the purpose of recycling, when there is no plan to actually ever use that material?”

The work will be presented at the ACM Symposium on User Interface Software and Technology in September. With SustainaPrint, the researchers say the future of 3D printing doesn’t have to choose between strength and sustainability.