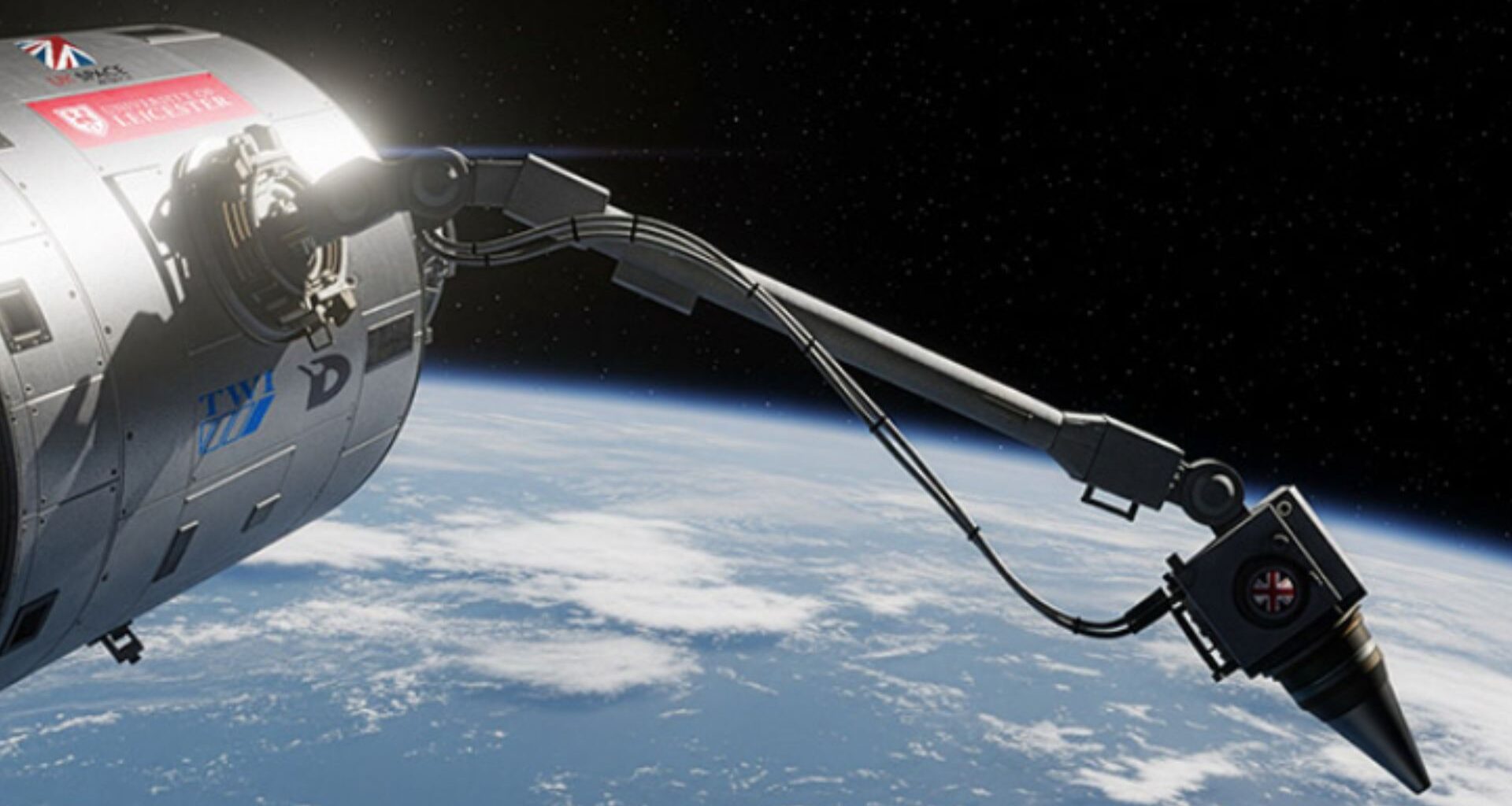

The University of Leicester, in partnership with welding specialist TWI Ltd, is leading the development of the UK’s first robotic welding capability for use in space.

The project, called ISPARK (Intelligent SPace Arc-welding Robotic Kit), has secured £560,000 in funding — including £485,000 from the UK Space Agency’s National Space Innovation Programme (NSIP).

Under this initiative, experts will create a robotic arc-welding system that can be mounted on a robot to perform in-space repair, joining, and manufacturing.

It will be specifically designed to work in the extreme challenges of space, including vacuum, microgravity, and thermal instability.

Robotic welding technology

Currently, if a satellite breaks or a large structure needs to be built, the entire component must be designed to fit on a rocket and survive the extreme forces of launch.

Welding in space removes these limitations. However, it is not a straightforward task, and it becomes brutally difficult.

It faces a host of extreme and dangerous factors: vacuum, microgravity, intense thermal instability, and high radiation.

Astronauts would face severe physical strain while performing welding tasks under these harsh conditions.

For decades, these barriers have made in-orbit repair incredibly rare and complex, pushing space agencies toward a costly “use and discard” paradigm.

ISPARK is here to change that with new, space-qualified robotic welding technology.

Dr Daniel Zhou Hao, Principal Investigator from the University of Leicester, emphasized the project’s global impact. He said, “By combining Leicester’s strengths in AI robotics and space engineering with TWI’s world-leading welding expertise, we are developing an enabling technology that could redefine how large structures are built and maintained in orbit.”

The key to mastering these cosmic conditions lies in digital-twin modelling.

Scientists will simulate the harsh vacuum and complex thermal environments of space on Earth.

Every robotic weld performed in the lab will be validated against this digital model, ensuring the technology is robust enough for real-world application before it ever leaves the atmosphere.

Professor Dirk Schaefer, Pro-Vice-Chancellor at the University of Leicester, framed ISPARK as a milestone in this new era.

“Developing the UK’s first in-space robotic welding capability is not only a scientific and engineering milestone, but it also supports a more responsible and resilient space economy,” he explained.

This technology promises to reduce waste, extend mission lifetimes, and enable the eventual construction of larger, more complex orbital infrastructure, from advanced telescopes to future space stations.

Other initiatives for welding in orbit

Efforts to develop space-based welding systems for satellite repair and extended mission life are global, with several teams actively pursuing this technology.

For instance, US-based ThinkOrbital has successfully demonstrated the world’s first autonomous in-space welding system through experiments.

Meanwhile, a team at the University of Texas is tackling the challenge by creating a virtual environment that precisely simulates conditions on the lunar surface.

It will allow them to safely and cost-effectively test and troubleshoot various techniques, including electrical arc, laser, and electron-beam welding, before moving to actual missions.

If these endeavors come to fruition, space welding will be able to transform space operations from a series of expensive, one-off missions into a self-sustaining, long-term economic and exploratory ecosystem.