The 3D-printed DIY telescope (pictured in hands-on photos) uses carbon rods for structural support. (Image source: Lucas Sifoni)

The 3D-printed DIY telescope (pictured in hands-on photos) uses carbon rods for structural support. (Image source: Lucas Sifoni)

Lucas Sifoni documents a pocket-sized, 3D-printed Dobsonian telescope built around a 76 mm mirror. The project details its compact mechanical design, materials, optical testing, and limits, showing it is small but genuinely functional.

A personal project shared by developer and hobbyist Lucas Sifoni from November 18, 2025 documents the design and testing of a very compact, fully functional Dobsonian telescope, which was built with portability as its primary constraint.

According to the project notes, the telescope was designed to fit inside the inner pocket of a jacket, with the exception of its carbon rods – which is still quite impressive. The build is based around a 76 mm parabolic mirror with a 300 mm focal length, which becomes a part of a fast f/4 optical system. The structure itself is entirely 3D-printed, using PETG carbon-fiber filament for rigidity’s sake, all while keeping the overall weight low.

The mechanical design follows classic Dobsonian principles – prioritizing balance, smooth movement, and simplicity. The altitude and azimuth motions (changes in the horizontal direction of an object) rely mostly on improvised Teflon-style pads made from UHMW or HDPE furniture feet, which are then paired with rubber backing. Carbon rods are used for structural support and intentionally forced into a slight arch so as to lock the assembly in place. Nylon screws are present for collimation of both primary and secondary mirrors, all while magnets hold the secondary mirror in position.

Regarding focusing, it is handled through a friction-based eyepiece holder. The eyepiece slides directly within a printed tube and is held in place through plastic flexion, which eliminates the need for any additional hardware. A light Lycra shroud is used both to block stray light and slow down dew formation on the mirrors.

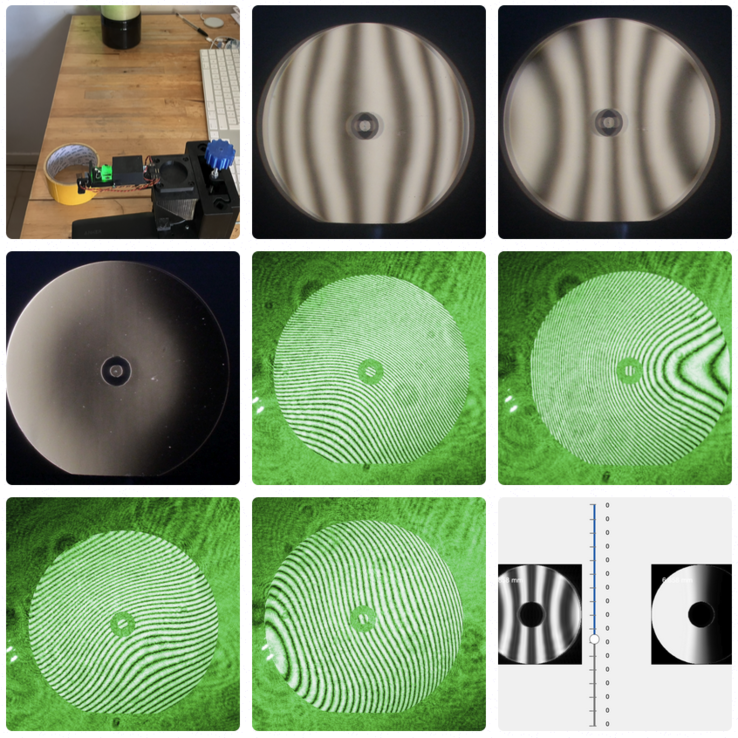

Optical testing shown in the screenshots includes interferograms and star tests conducted before and after mirror refiguring. Initial results show that the mirror was significantly overcorrected out of the box, which is a pretty common issue with inexpensive spherical mirrors. After refiguring, however, the builder reported improved star symmetry and usable performance at around 0.9 Strehl (which means it delivers about 90% of the maximum sharpness that a theoretically perfect mirror of the same size could achieve), though the small mirror size does limit resolution.

The project documentation explicitly states that while the telescope isn’t competing with larger commercial instruments, it does succeed as a genuinely usable optical device at an unusually small scale. The 3D files are publicly available, along with assembly notes and optical test results, in case you’re interested in replicating or modifying the design.

Buy the Celestron Travel Scope 80 Portable Refractor Telescope on Amazon.

Pre-refiguring test pictures from the telescope. (Image source: Lucas Sifoni)

Pre-refiguring test pictures from the telescope. (Image source: Lucas Sifoni) Anubhav Sharma – Tech Writer – 1237 articles published on Notebookcheck since 2024

Anubhav Sharma – Tech Writer – 1237 articles published on Notebookcheck since 2024

Most of my time goes into writing – and somehow it hasn’t stopped being fun yet.

My work mainly revolves around everyday tech, gaming, watches, DIY modding, and the occasional piece on tech-policy chaos when companies and governments clash. I try to keep things simple and honest, without sounding like a product brochure.

I have a Bachelor’s degree in Computer Science Engineering and an Associate Degree in English Studies from the College of New Caledonia in British Columbia, Canada.

Away from articles and deadlines, life usually shifts to making music, taking photos, or trying to finish games that should have been completed months ago.

Anubhav Sharma, 2025-12-13 (Update: 2025-12-13)

10