Williams can easily be considered the ‘best of the rest’ this season, with the FW47 having helped deliver a fifth place finish for the team from Grove.

However, they’ve done so on a string-shoe budget when it comes to the amount of resources spent on improving their car during the season, so let’s take a look at some of the details that have helped them throughout their campaign and some of the limited changes that have been made too.

A good base

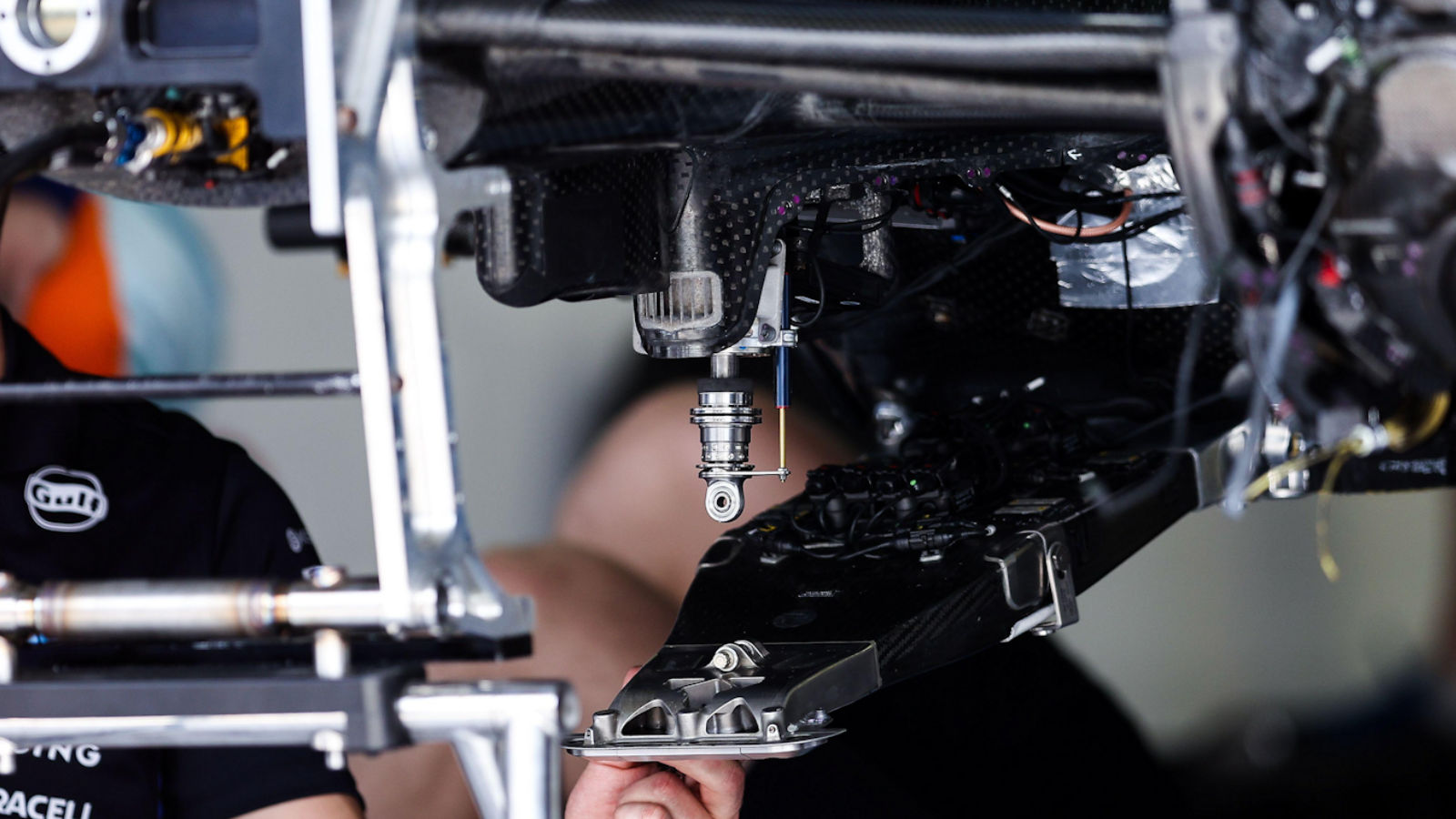

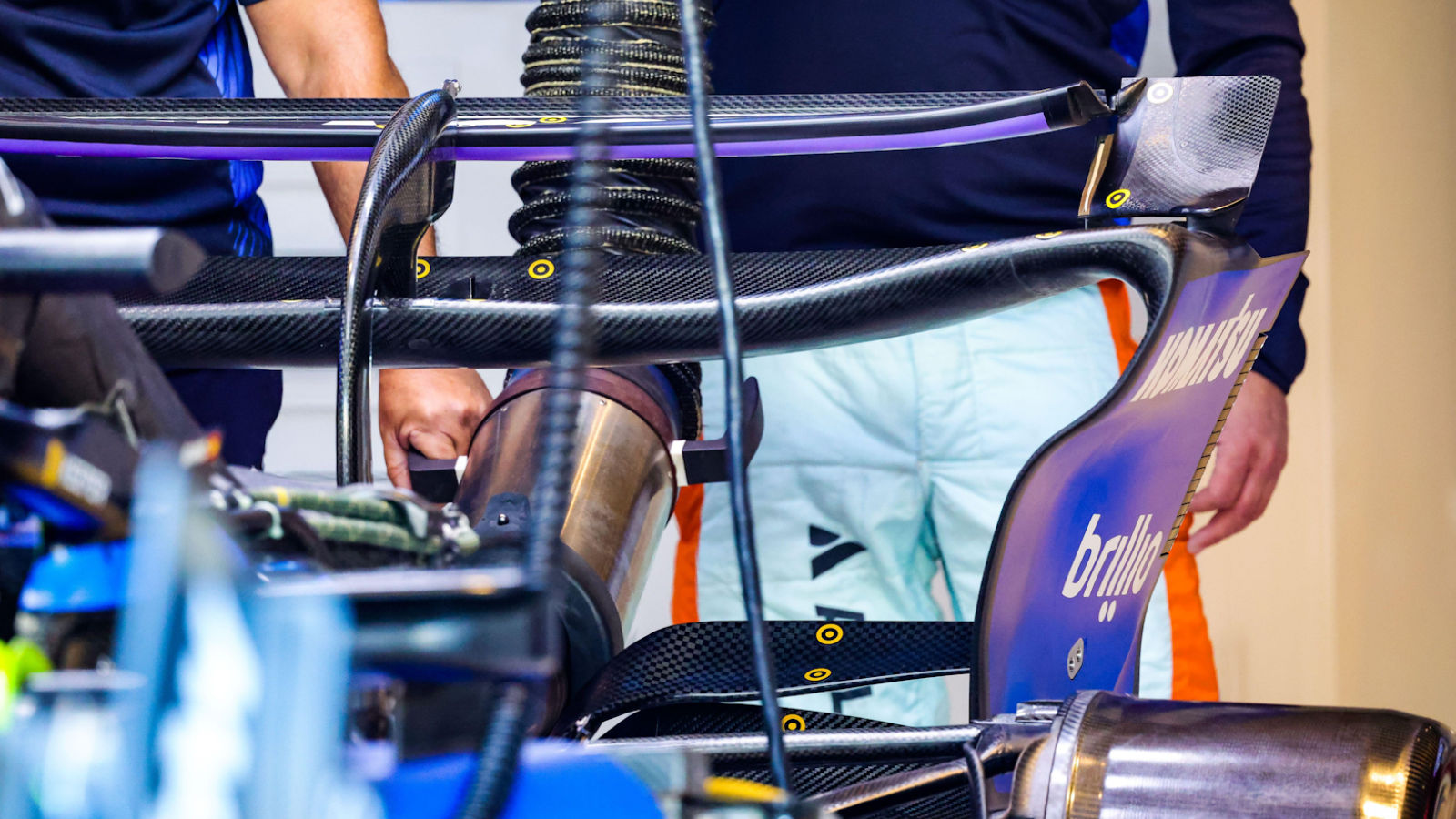

A mechanic works on the attachment of the FW47’s bib to the spring mechanism hung from the underside of the chassis.

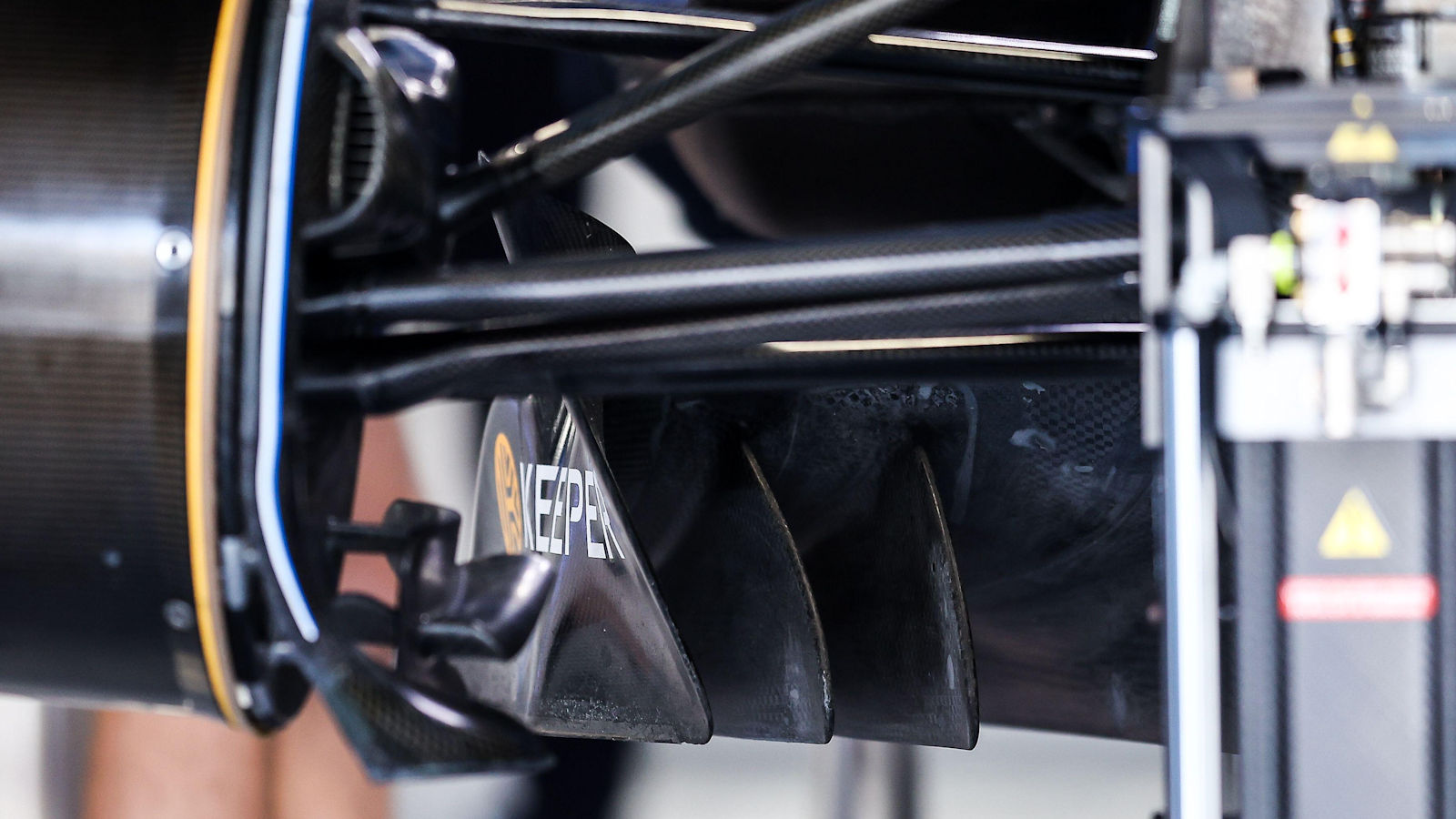

A close-up of the outer three fences on the FW47’s floor, which are shaped to help reduce the negative effect the turbulence from the front wheel might have on the flow to the underfloor.

A large quantity of flo-viz was painted on the FW47 during pre-season testing as the team looked for visual confirmation that those areas were performing, aerodynamically, as they expected.

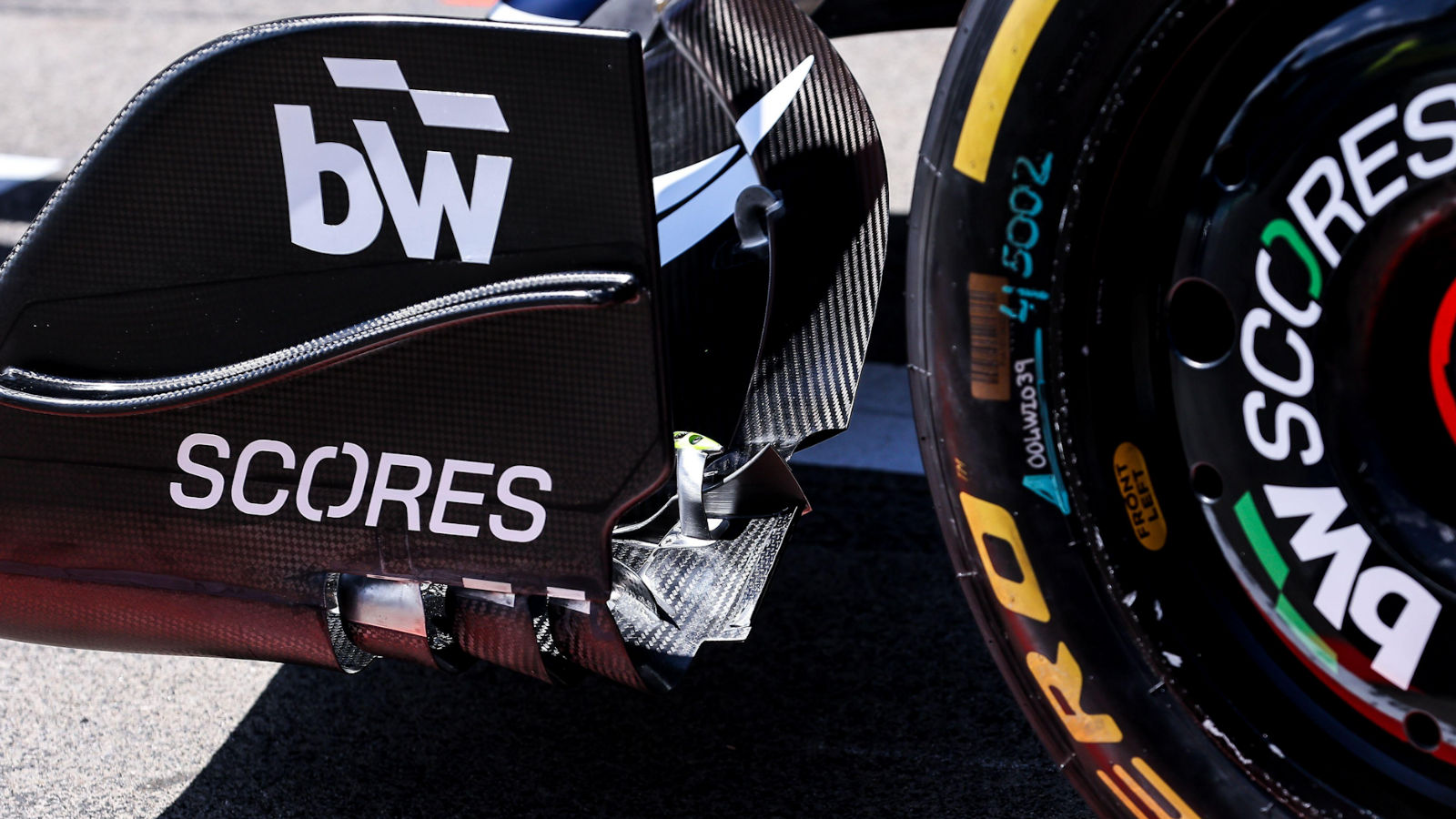

A close-up of the metal brackets,separators and adjuster mounted around the flap split line on the FW47’s front wing.

An unusual view of the front wing and nosecone is captured during pitstop practice at Williams.

A side view of the front wing provides insight into the outermost section of the assembly, with the semi-detached flap layout skewed relative to the endplate.

Perhaps taking inspiration from Aston Martin, who’d already ran a similar solution, Williams altered the front wing upper flap’s DNA by adding a V-shaped notch at the Japanese Grand Prix (arrowed).

A top-down overview of the front wing and sidepod and engine cover bodywork from the FW47, as they sit waiting to be installed outside the garage.

Williams mechanics work separately on the rear crash structure, gearbox and suspension on the FW47 before it’s attached to the chassis.

A close up of the halo’s rear leg and the bodywork around it and where it’s connected to the chassis. Notably it has a thin topline and a winglet mounted on the side to help minimise some of the aerodynamic losses associated with the overall installation of the safety structure.

The Williams FW47 sat on the stands in the garage with just the sidepod and engine cover bodywork left to go on. Notably the outer front brake drums are in place too.

Another view of the FW47 on the stands as it’s prepared for action, albeit this time the outer front brake drums aren’t installed, which provides us with a view of the disc and caliper fairings below.

A close up of the rear brake duct assembly, with the caliper and disc fairings in place but the outer drum has yet to be installed.

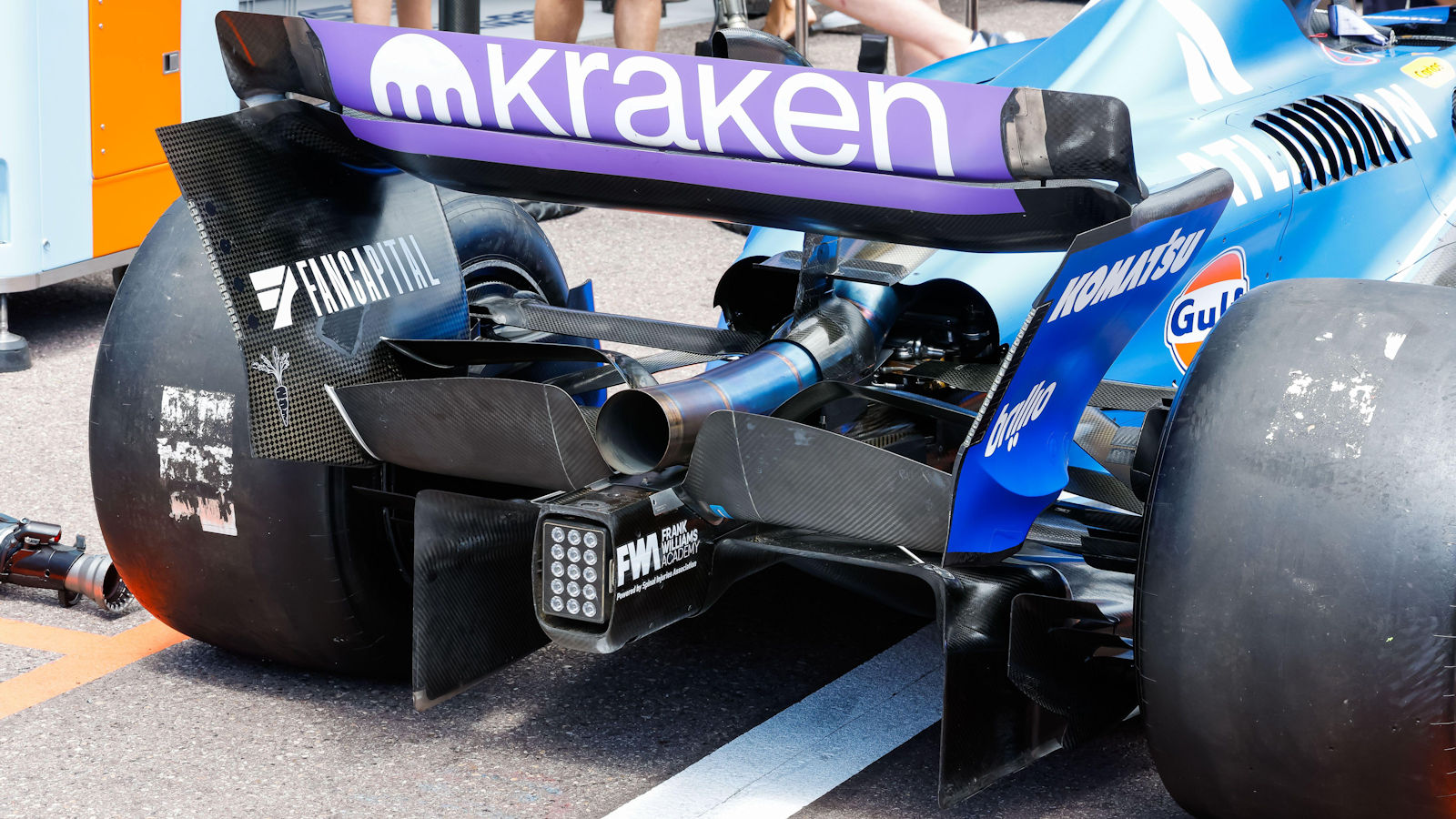

The rear end of the FW47 in high downforce trim, including a bi-plane style beam wing arrangement, a T-Wing mounted to the rear wing support pillar and a rear wing arrangement that takes up most of the allowable box region.

Williams tried a different approach for their rear wing tip section at the beginning of the season, taking a notch out of the upper corner.

The Williams FW47’s rear wing with the upper flap open, as if DRS was being employed, allows us to see how it has a cutout section so it overlaps with the tip section when it closes.

Williams painted flo-viz on the FW47’s rear wing assembly during pre-season testing to assess if it was performing as their simulations had predicted.

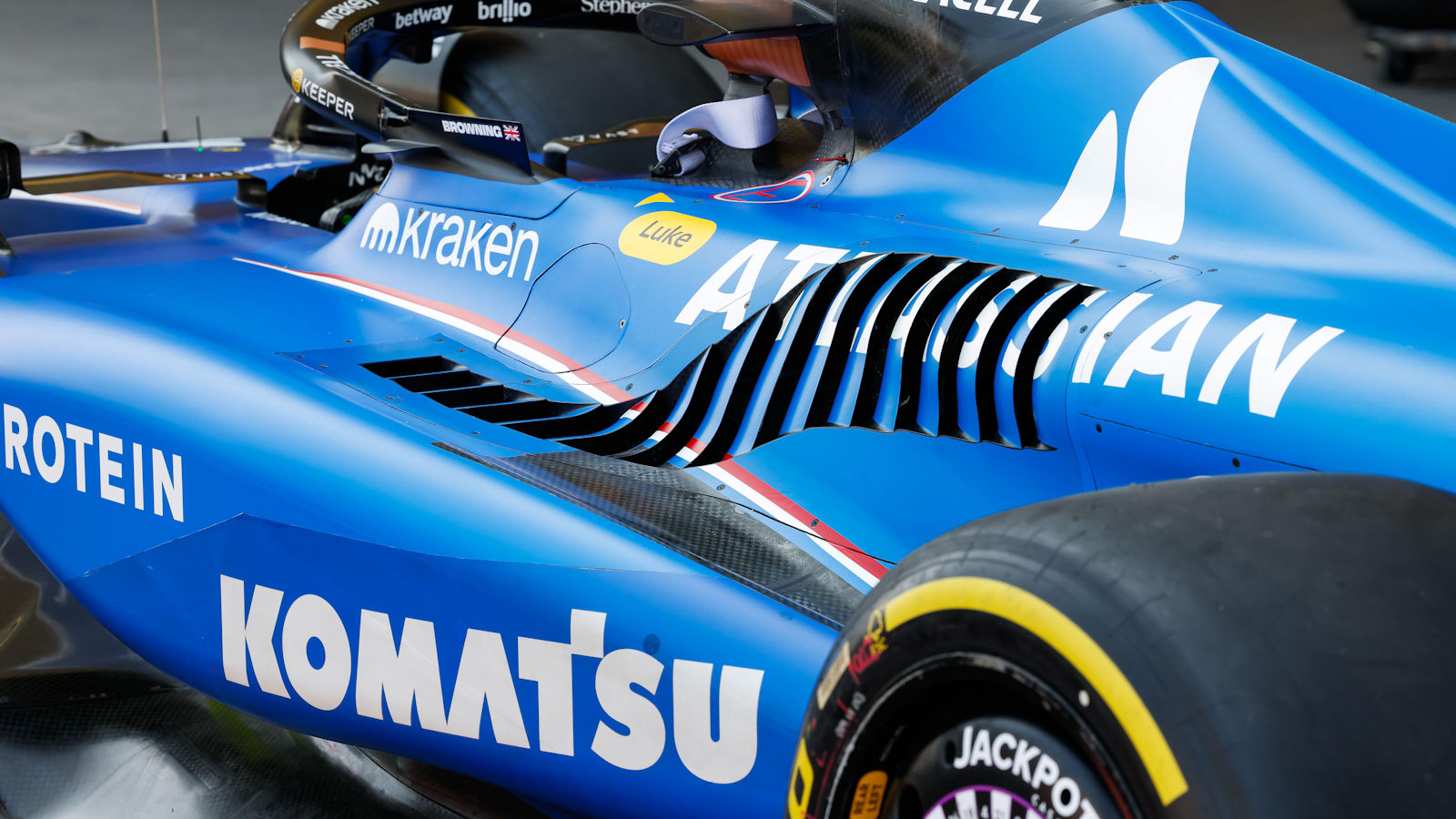

An elongated cooling louvre layout could be seen working down the sidepod and over the engine cover of the FW47 when extra cooling was required.

Williams introduced a revised sidepod layout at the Belgian Grand Prix, which altered the shape of the G-line and undercut.

The Belgian Grand Prix update also resulted in a revised layout for the inlet, with a new shape and size employed to improve cooling.

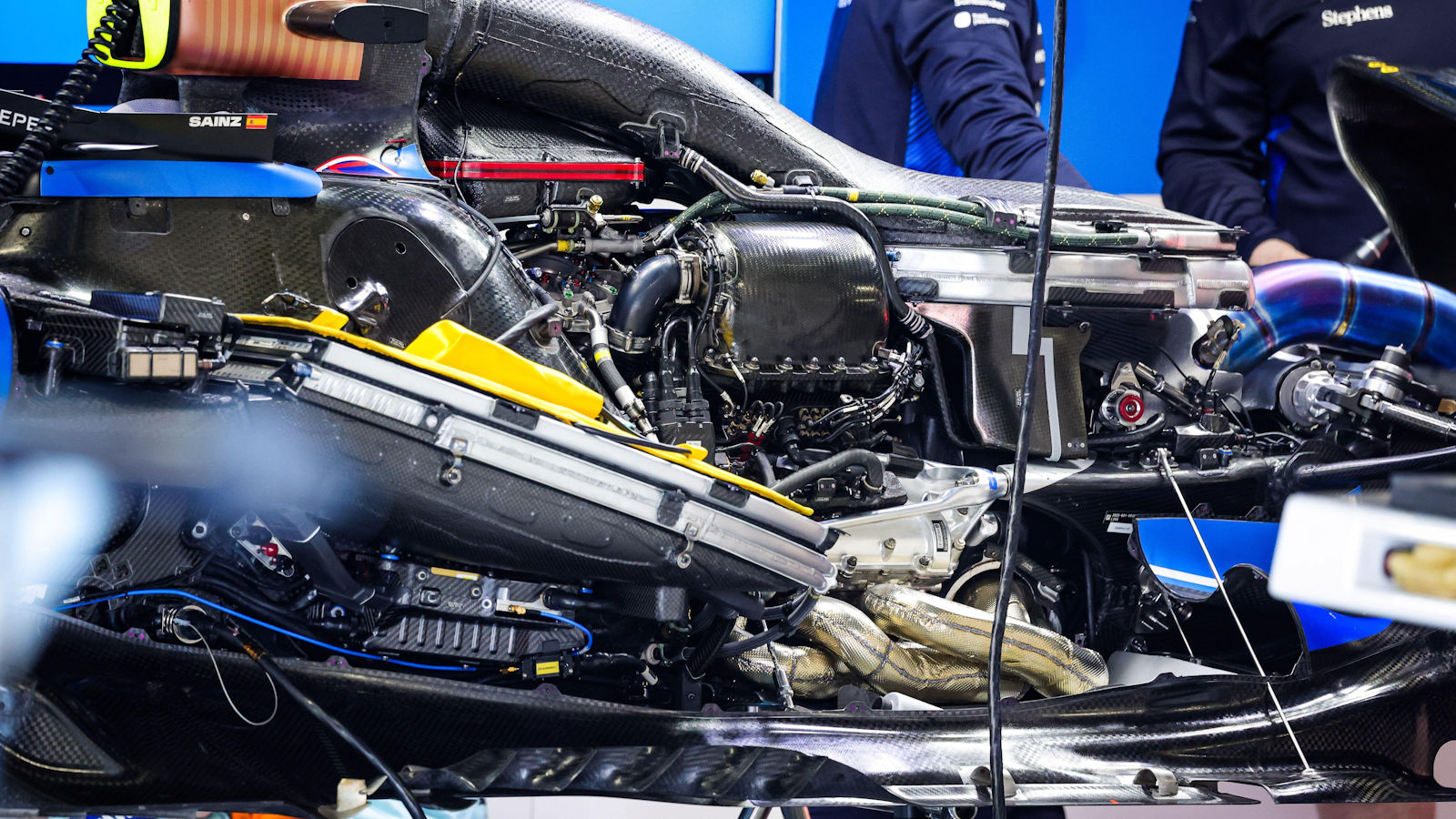

A side-on view of the powerunit and ancillaries installation within the FW47, with it apparent how the exhaust has to snake its way over the top of the inboard suspension components.

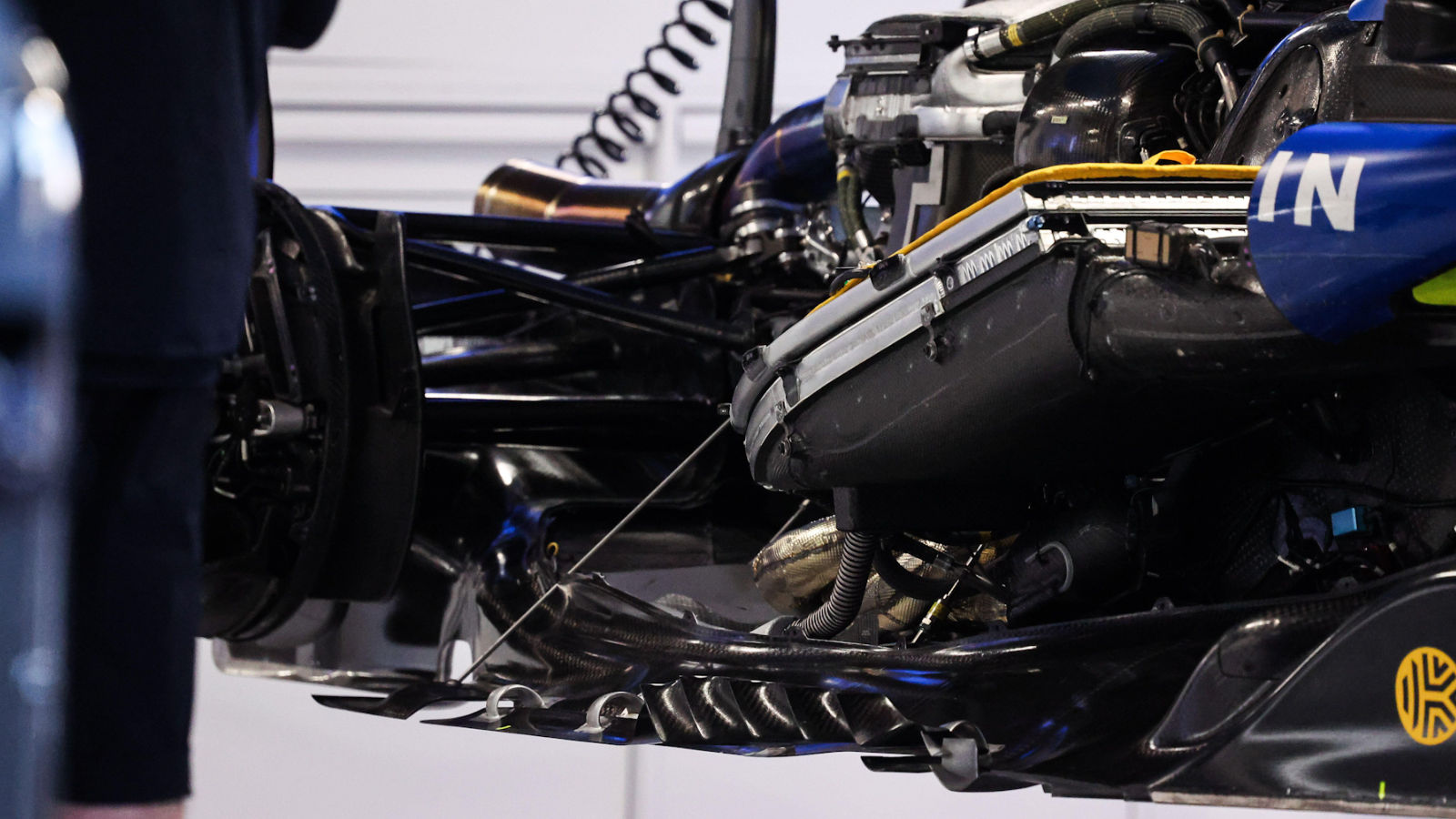

Another look at the internal layout of the Williams FW47, including the more horizontally stacked coolers within the sidepod and metal stays used to support the floor. It also provides a nice view of the floor’s edge wing, including the various strakes and metal supports used to help control the airflow around the assembly.

Want to be the first to know exclusive information from the F1 paddock? Join our broadcast channel on WhatsApp to get the scoop on the latest developments from our team of accredited journalists.

You can also subscribe to the PlanetF1 YouTube channel for exclusive features, hear from our paddock journalists with stories from the heart of Formula 1 and much more!

Read next: F1 uncovered: Under the skin of the Racing Bulls VCARB02