A new study by solar recycling firm SOLARCYCLE and Arizona State University (ASU) has confirmed that solar panels manufactured with recycled glass perform identically to new panels.

The finding is a significant development for creating a sustainable, domestic supply chain for the renewable energy sector.

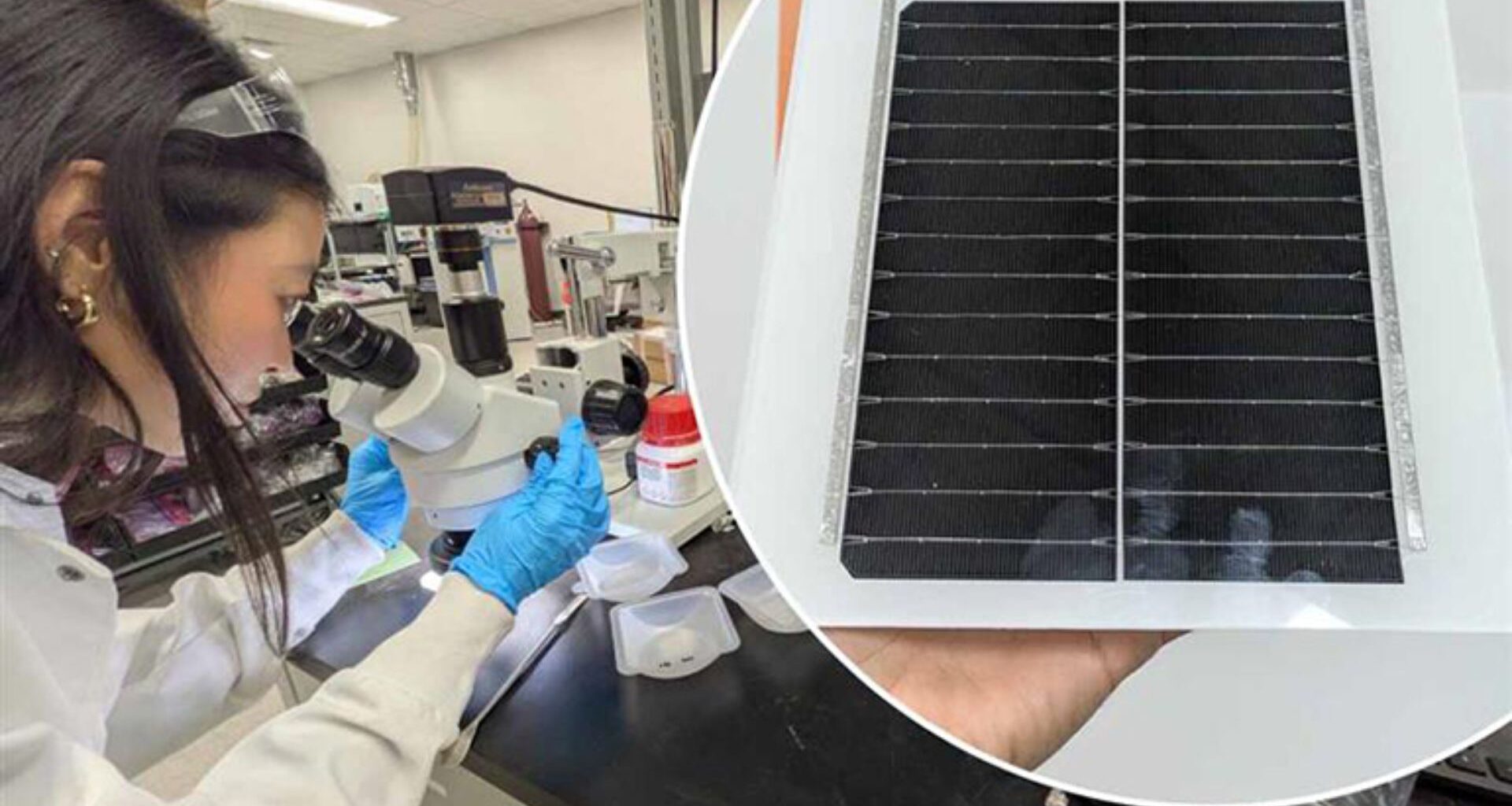

The joint research project successfully produced and tested prototype solar panels, called “mini modules,” using a blend of 50% recycled glass and 50% new glass.

No difference in power-conversion

When evaluated, these modules showed no statistically significant difference in power-conversion efficiency or performance compared to control panels made entirely from virgin materials.

“Using industry-standard power-conversion efficiency tests, researchers evaluated both sets of modules and found that the modules built with recycled glass performed as well as those made with virgin glass, with no statistically significant differences across any key metrics,” said SOLARCYCLE in a press release.

The study was conducted at ASU’s Ira A. Fulton Schools of Engineering, under the leadership of Dr. Zachary Holman, the university’s vice dean for research and innovation.

ASU researcher Kate Fisher fabricated the modules for the experiment. The recycled glass cullet used in the test panels was sourced from end-of-life solar panels processed using SOLARCYCLE’s proprietary technology.

“Together, we proved that you don’t have to sacrifice performance to build solar panels more sustainably,” said Dr. Holman.

“It’s not just a lab success—it’s a path forward for the industry.”

Validating SOLARCYCLE’s technology

This research validates SOLARCYCLE’s mission to create a closed-loop system for solar panel manufacturing. By using recycled materials, the company aims to reduce waste and strengthen the solar supply chain.

“By proving we can manufacture new solar panels using recycled materials that produce at peak performance levels, we’re taking a major step toward making the solar industry more sustainable, scalable, and self-reliant,” stated Pablo Dias, Chief Technology Officer and Co-Founder at SOLARCYCLE.

Building on these results, SOLARCYCLE is moving forward with plans to construct a solar glass factory in Cedartown, Georgia.

The facility will be the first of its kind to use recycled glass cullet as a primary input, directly applying the process validated by the ASU study.

Growing trend of recycling

Earlier, SOLARCYCLE had announced plans to set up a massive recycling plant in Cedartown, Georgia. The new 5 gigawatts (GW) facility, slated for completion in 2025, will initially have the capacity to recycle 2 million panels per year, with expansion plans as demand grows.

There is a growing trend of recycling solar panels. A California-based company, PV Circonomy, has unveiled a proprietary automated technology for solar panel recycling. With a 99.3% material recovery rate, the company’s technology reduces waste and allows for the reuse of valuable resources.

Researchers in Sweden have developed a novel method that recycles all parts of solar cells repeatedly without environmentally hazardous solvents. Also, the recycled solar cell delivers the same output as the original one.