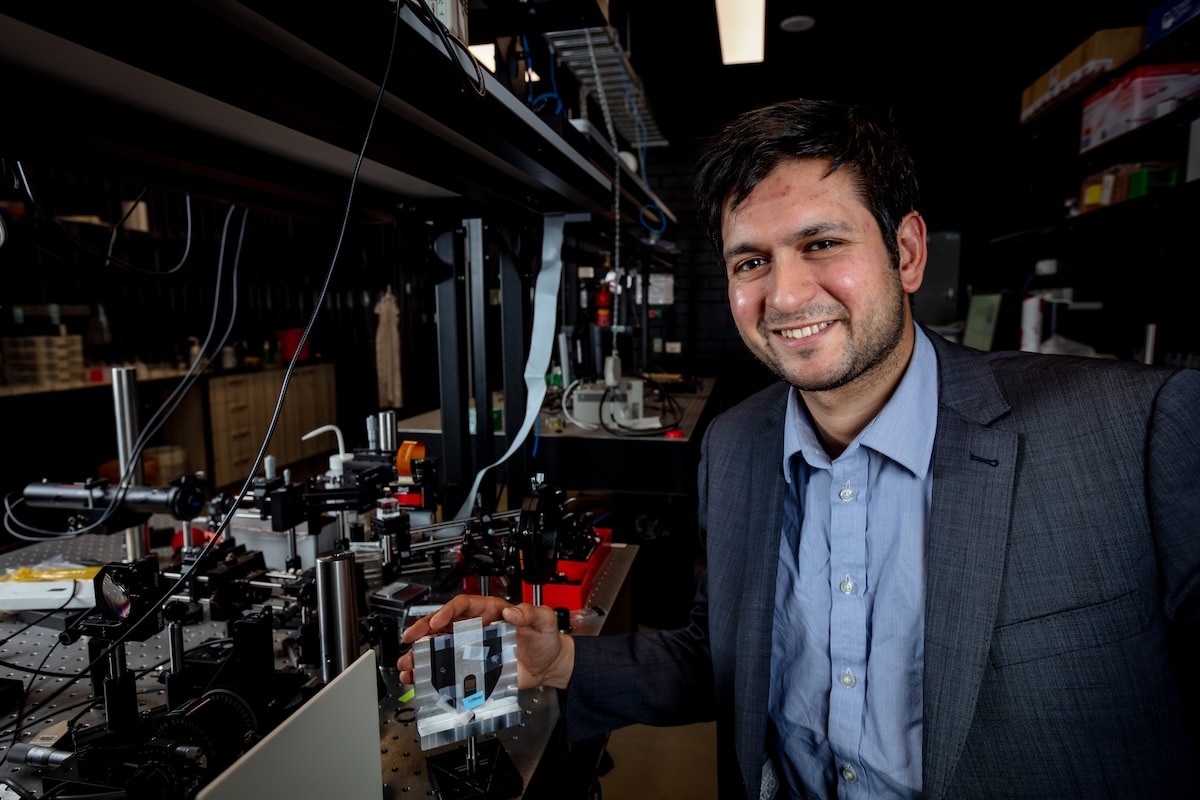

Manufacturers’ Monthly spoke with Professor Brain Abbey from La Trobe University on the scale up manufacturing of nanotechnology devices.

In 2023, the Federal Government introduced the $1.6 billion Economic Accelerator (AEA) scheme, a government initiative designed to help commercialise Australian based academic research.

One notable recipient of an AEA grant was Professor Brian Abbey from La Trobe University’s School of Computing, Engineering and Mathematical Sciences (SCEMS) and the La Trobe Institute for Molecular Science (LIMS). In July of this year, he was awarded a fund of $2.5 million to scale up the manufacture of nanotechnology devices as a part of an $8.1 million package for three La Trobe research projects.

With the funding, Abbey is partnering with AlleSense, a La Trobe start-up, which aims to commercialise their nanotechnology device, NanoMslide, and scale up its manufacture.

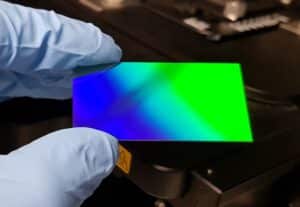

The NanoMslide is a nanofabricated sensor technology that enhances the contrast of microscopic tissue samples. Abbey shared its benefits in allowing easier, faster and more accurate diagnostic images. It is the same size as a standard microscope slide, with 14 billion sensors embedded in it. These sensors enable the detection of abnormal cells, such as cancer, directly in the tissue without using chemicals.

Abbey outlined the product’s potential, its scalable manufacturing process, and opportunities for future expansion. He highlighted the benefits it could bring to the manufacturing sector and its role in supporting national industrial growth.

Benefits to the Australian manufacturing industry

Abbey explained that while NanoMslide production has previously relied on overseas facilities, scaling up manufacturing in a new Australian facility will have a broader impact on the local manufacturing and medical industries. This will allow those later impacts to stay within Australia.

“I think having the opportunity not only to generate valuable new IP, but also to establish commercial manufacturing and commercialise here in Australia, is a huge advantage for us,” he said. “It means the jobs associated with that manufacturing will now be based in Australia rather than overseas, and that all the downstream infrastructure and support for those facilities will remain here – something I believe is a really positive outcome.

“It brings a capability that we don’t currently have in Australia, the mass production of nanoscale structures at whole wafer scales and at the highest quality.”

Additionally, Abbey explained that scaling up manufacturing can support local industry growth. By undertaking the bulk of commercialisation efforts in Australia for as long as possible, it can keep the downstream benefits of manufacturing remain within the local economy.

Opportunities for international growth

While manufacturing is underway in Australia, Abbey sees strong potential for the product on a global scale with positive feedback from collaborations with companies in the United States and Europe already emerging. Industry feedback and early engagement suggest it could successfully scale beyond domestic markets, with the potential to enter global markets in the near future.

“The end goal with this product, I think is absolutely to achieve a global impact, and I think our current intellectual property position supports that pathway,” said Abbey.

Demonstrating strong progress, Abbey said that the technology is showing potential to deliver a range of benefits. With these benefits in mind, one consideration in approaching the market will be whether current capabilities will be able to keep up with demand.

“Even though we’ve now got this scale-up facility, if the product takes off as we hope, demand may even exceed our current capabilities,” said Abbey.

A facility built for innovation

Behind the innovation is a new facility helping to prove that the team is able to make their device in scale. A part of this is a new clean room established by Abbey and his colleagues that is dedicated to manufacturing a product made for commercialisation.

“For us, a cleanroom means that all manufacturing equipment must operate in a tightly controlled environment, allowing no more than 100 particles per cubic foot,” said Abbey.

“We need that process to take place in a tightly controlled and regulated environment, which is defined by ISO certification, and we need to establish those new sovereign capabilities in Australia to enable high-volume manufacturing.”

While gaining access to shared clean room facilities is valuable for research and early-stage development, maintaining quality control can be challenging when multiple users share the same space. For commercial work that demands the highest standards, a dedicated clean room is essential.

“The facility we’ve been supported by the AEA to develop is essential for demonstrating that we can manufacture our medical devices at scale while maintaining the same quality standards and rigorous checks used during prototype production,” said Abbey.

With the new facility, Abbey outlined his goal of maximising device production to meet demand, while maintaining quality and achieving full circular wafer fabrication.

“We want to scale up our manufacturing so that we can produce thousands of devices per month. That’s our target, and we need to achieve it while meeting all our quality controls, as this will demonstrate our ability to manufacture at a scale sufficient to meet market demand and support large-scale clinical validation,” said Abbey. “We want to achieve a whole wafer – defined as a six-inch circular disc typically made of silicon, or in our case, glass – with high-quality, reproducible nanoscale features across the entire area.”

Abbey said that successfully navigating this complex stage will be crucial for the device to transition from a lab scale innovation to market-ready product in a widespread adoption.

Challenges for the scale up

Transforming the nanotechnology device from a lab scale to a manufacturing scale involves various challenges. With the aim to expand production capacity while maintaining quality, it is essential to make sure that the process delivers the consistent result and effect. There are different preparations that needs to be done throughout the process.

The main challenge in commercialising medical devices is to shift the product’s scale of manufacturing, as it is necessary to demonstrate that the performance of the device remains consistent when produced at scale.

Given that medical devices are highly regulated, clinical trials are required to validate the technology and for regulatory approval. Furthermore, large-scale manufacturing often differs from prototyping.

“There are significant differences between the way in which you manufacture at small scale versus the way you manufacture at large scale, that could potentially be a barrier to commercializing because you then need to revalidate using your scaled manufacturing process,” said Abbey. “For medical technologies we typically need to present regulatory bodies with clinical evidence and data that includes describing how you manufacture the technology.”

Abbey mentioned that producing high-tech nano scale manufacture in a large volume while maintaining high quality standards is important, but challenging.

“That’s a difficult combination and it is quite a challenge to manage both of those competing priorities,” said Abbey. “If large-scale manufacturing differs from the prototyping process, the technology may need to be revalidated, as the new manufacturing method must be submitted for regulatory approval.”

It is critical to enable validation and provide sufficient evidence and data to demonstrate the relevance and reliability of the performance prior to ideally submitting the product for regulatory approval. Additionally, it is also important to determine whether these devices are produced enough to meet the market demand.

“Scaling up manufacture is often a big hurdle for companies and particularly in the medical space,” said Abbey.

While the scale-up presents potential opportunities, Abbey said it is vital to address these challenges, ensuring its successful implementation and long-term growth. As there are different issues and dynamics that can involve in the transition, early preparation will be an advantage, enhancing the overall effectiveness of the scale-up process.

“Being able to have that chain of evidence prior going to the regulatory body is very powerful for us to streamline the time to market,” said Abbey.