Chinese robotics player UBTECH has marked a major milestone with the rollout of its 1,000th Walker S2 humanoid robot from its Liuzhou manufacturing plant.

The achievement signals a shift from experimental prototypes to scalable, real-world deployment. More than 500 Walker S2 units have already been delivered and are operational across multiple applications.

UBTECH now plans to significantly ramp up production capacity, targeting output of up to 10,000 units annually by 2026.

In November, the Shenzhen-based firm claimed that it had already shipped hundreds of its Walker S2 humanoid robots to active industrial facilities.

Humanoids power factories

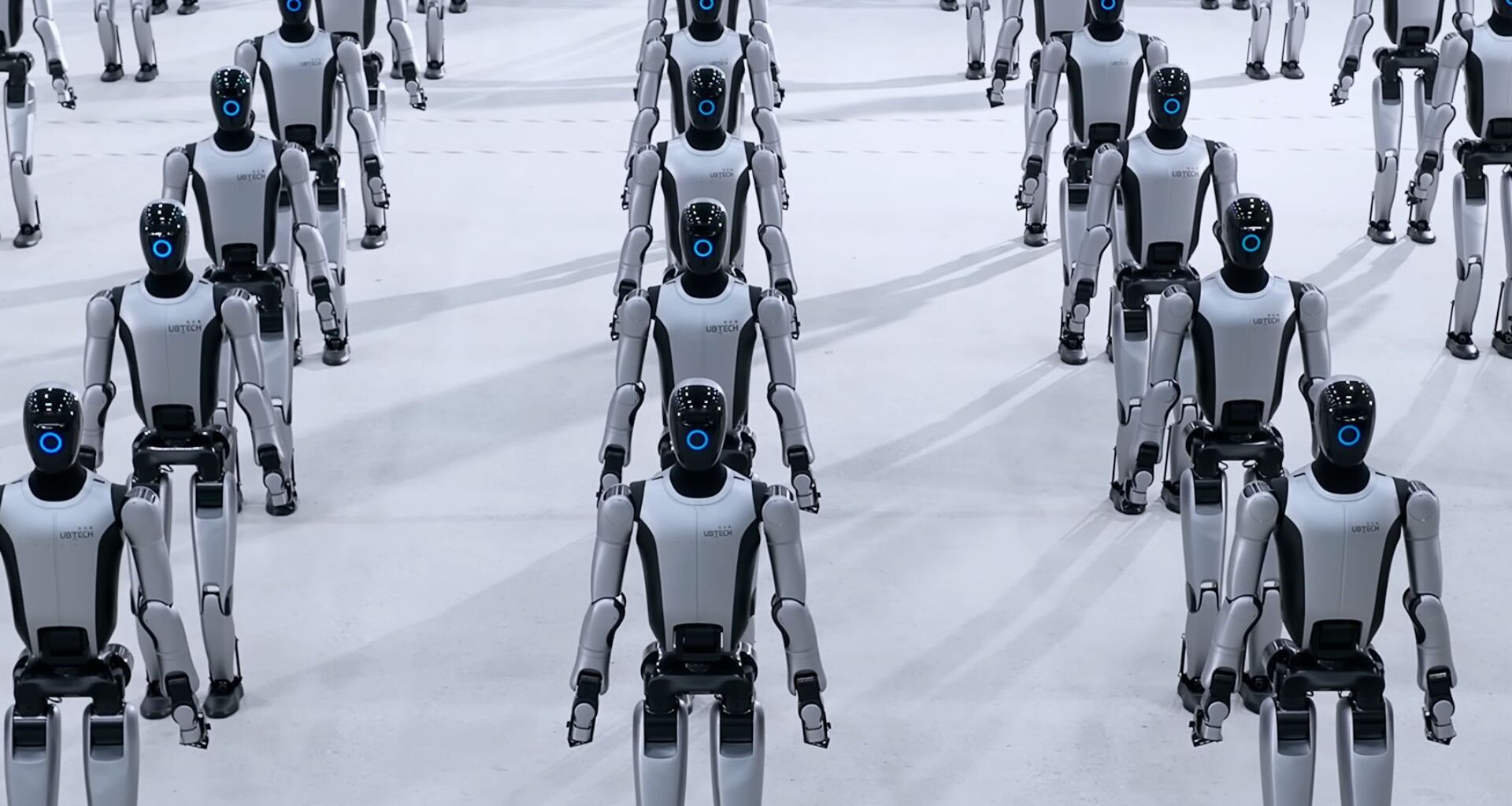

A video shared by the company on YouTube shows hundreds of Walker S2 humanoid robots lined up in perfect formation in front of a poster marking the 1,000th rollout. The footage also features a humanoid robot wearing a cap and scarf, performing a stylish celebratory dance to mark the occasion.

The company is seeing strong interest from organisations looking to automate physically demanding tasks typically carried out by workers who spend long hours on their feet.

This year, UBTECH secured orders worth about 800 million yuan (roughly $113 million), covering everything from customised installations to large-scale deployments. One of the biggest deals was signed in September, when a well-known Chinese company placed a 250 million yuan ($35 million) order for an advanced robotic system. Another major customer in Sichuan committed 159 million yuan ($22.5 million).

According to the South China Morning Post, a project in Guangxi has pledged 126 million yuan ($17.9 million), while Midea Auto in Hubei has committed more than 100 million yuan ($14.2 million). UBTECH has planned to deliver 500 Walker robots by the end of December and says it remains on track to meet that goal, which it has now achieved.

According to UBTECH, automakers are driving much of the demand. Companies such as BYD, Geely Auto, FAW Volkswagen, and Dongfeng Liuzhou Motor have signed on, while Foxconn is deploying robots to support logistics operations. These customers are seeking stable, round-the-clock operations with minimal supervision, and early trials show the robots performing reliably in real factory and warehouse environments.

Humanoids spark debate

Recently, UBTECH drew global attention after releasing footage showing hundreds of its humanoid robots moving in synchronized formation inside a warehouse, prompting both fascination and skepticism. The video, widely shared online, even led US robotics executive and Figure CEO Brett Adcock to question whether the scenes were computer-generated publicly.

The Shenzhen-based company has firmly rejected those claims, defending the video’s authenticity and pointing to China’s large-scale manufacturing capacity and highly coordinated supply chains. The footage, reminiscent of scenes from the sci-fi film I, Robot, shows rows of Walker S2 humanoid robots turning their heads, waving, and marching into shipping containers.

UBTECH says the video marks a major milestone, claiming it has begun mass deliveries of its Walker S2 robots to real industrial partners. According to the company, production was ramped up in mid-November, with the first batch already shipped to customers seeking additional labour for assembly lines. UBTECH says the rollout demonstrates that humanoid robots are moving beyond laboratory prototypes into practical, real-world deployment.

However, doubts persist. Adcock argued on social media that visual inconsistencies, particularly reflections on the robots, suggested heavy CGI use. In response, UBTECH released additional footage, filmed with a first-person drone and raw audio, insisting the material was shot on site.

Looking ahead, UBTECH aims to sharply expand its manufacturing capacity, with plans to produce 5,000 industrial humanoid robots annually by 2026 and further scale up to 10,000 units a year by 2027.