Hydrogen – New research could lead to greener, faster metal production

Most metals found in nature are actually in their oxide forms. To extract those metals to use in critical applications — ranging from infrastructure such as bridges and buildings to advanced technologies like airplanes, semiconductors or even quantum materials — those oxides must be reduced with gases. A new study illuminating how different gases can affect oxide reduction, however, has the potential to revamp scientific understandings and current industrial practices.

Hydrogen or carbon monoxide are typically used as reductants, presumed to get the job done similarly enough. This research highlights, for the first time, distinct variations between the two that affect the critical chemical reactions fueling metal production.

Published in Nature, one of the world’s leading scientific journals, the new paper was a collaboration between Binghamton University and Brookhaven National Laboratory, as well as Stony Brook University and Columbia University.

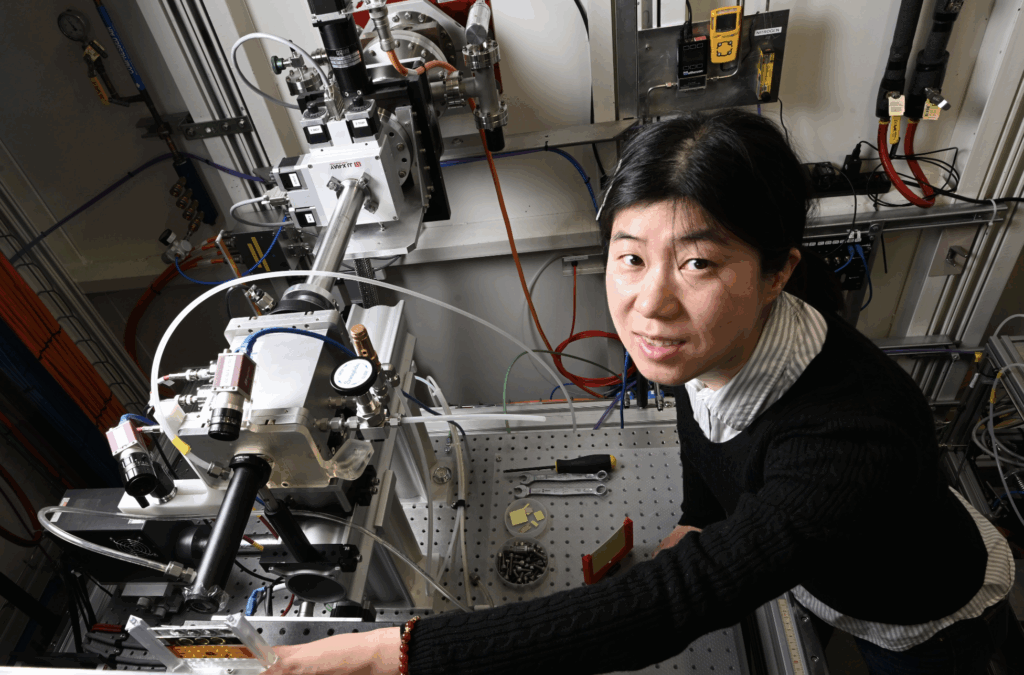

Guangwen Zhou, a SUNY distinguished professor at the Thomas J. Watson College of Engineering and Applied Science and deputy director of Binghamton University’s Materials Science and Engineering program, said :

For metal production, the key challenge is efficiently removing atomic oxygen from metal oxides to yield pure metals,

“The goal is to drive this reduction process using less energy, at lower temperatures, and with minimal carbon dioxide emissions. Our study offers insights that can help guide the choice of gases or reductants to accelerate reaction kinetics, making metal extraction faster, cleaner and more energy efficient.”

Carbon monoxides have raised concerns for their role in releasing harmful greenhouse gases during manufacturing. The findings of this study point to hydrogen as a greener alternative for metal production, capable of speeding up the process in a more sustainable manner. All this happens while generating benign water vapor as a much more benign chemical consequence.

Members of Zhou’s research group have been working on oxides for a long time, according to Binghamton doctoral student and first author Xiaobo Chen, but they gradually began noticing discrepancies in reduction reactions when using one gas versus another.

After prying into the mechanisms of each reducing agent, they found that carbon monoxide and hydrogen reductants aren’t actually so similar. When carbon monoxide was used to reduce nickel oxide, the oxide’s surface gradually grew coated with a thin layer of metal — essentially stopping any more catalytic reactions from occurring as oxygen depleted from the top. Trapped and unable to migrate into the bulk, those pockets lacking oxygen accumulated at the surface and drove the local conversion of nickel oxide into metallic nickel.

This newly formed metallic “crust” further blocked oxygen from being removed deeper within the oxide, slowing the overall reduction process. In addition to carbon dioxide emissions, continuing to wring any reactions out of a now inactive oxide would be even more costly and time-consuming.

Zhou said,

If we look at CO — because it’s mostly used as a method for metal production — if metal forms on the surface, it can block active sites and slow down the reaction kinetics,

“That makes the extraction process more difficult, which means you need to use more energy and higher temperatures.”

In contrast, when hydrogen was used, oxygen vacancies formed at the surface could migrate into the bulk of the oxide, enabling metal formation throughout the interior. Importantly, the surface remained largely intact with hydrogen, still capable of the catalytic reactions that are crucial for jumpstarting chemical reactions.

Zhou said,

All this difference is related to the difference in the fundamental mechanisms,

“I think that’s the reason the community has a strong interest in this work, because we’ve provided this fundamental insight to understand these two basic reductant gases in controlling reactions — in both kinetics and reaction products.”

And because hydrogen protons help oxygen vacancies more easily migrate away from the surface, that also raises the possibility of replenishing them through counterdiffusion of atomic oxygen from the oxide’s interior to its surface — a self-healing behavioral quirk that oxides exhibit. Zhou has also studied this mechanism in a paper published earlier in June, in the Proceedings of the National Academy of Sciences.

Zhou said,

If we use hydrogen, we can facilitate this process. For industrial applications, we can have that catalyst regeneration, without interrupting the catalytic process,

“The reaction itself may actually build or provide some self-healing capabilities to make the catalyst last longer.”

READ the latest news shaping the hydrogen market at Hydrogen Central

Hydrogen – New research could lead to greener, faster metal production, source