Acid Filling and Leveling Machine Market Forecast and Outlook (2025-2035)

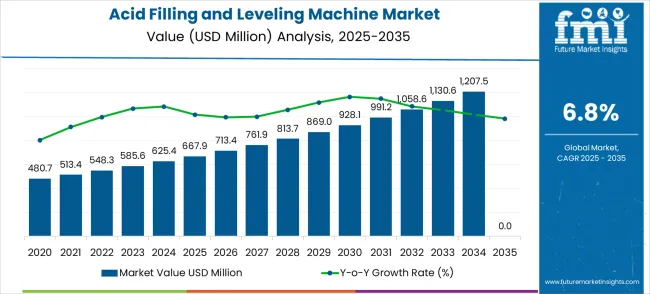

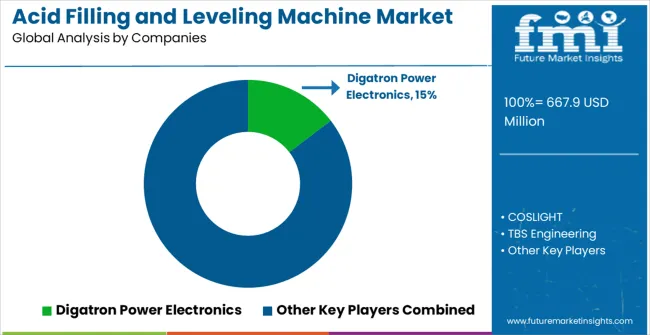

The acid filling and leveling machine market is expected to experience robust growth from USD 667.9 million in 2025 to USD 1,289.6 million by 2035, with a compound annual growth rate (CAGR) of 6.8%. The increasing demand for precision filling and leveling solutions in industries such as pharmaceuticals, food and beverages, and chemicals is driving this growth. Acid filling and leveling machines are integral to maintaining product quality and consistency, ensuring accurate and uniform filling levels in production lines. The need for these machines is further amplified by the growing trend of automation in manufacturing processes. As industries increasingly focus on efficiency and cost-effectiveness, the use of acid filling and leveling machines has become indispensable. These machines provide enhanced productivity, minimize operational waste, and reduce human errors, making them essential in environments that demand stringent quality control.

Quick Stats for Acid Filling and Leveling Machine Market

Acid Filling and Leveling Machine Market Value (2025): USD 667.9 million

Acid Filling and Leveling Machine Market Forecast Value (2035): USD 1,289.6 million

Acid Filling and Leveling Machine Market Forecast CAGR: 6.8%

Leading Automation Level in Acid Filling and Leveling Machine Market: Fully Automatic Acid Filling and Leveling Machine (48.0%)

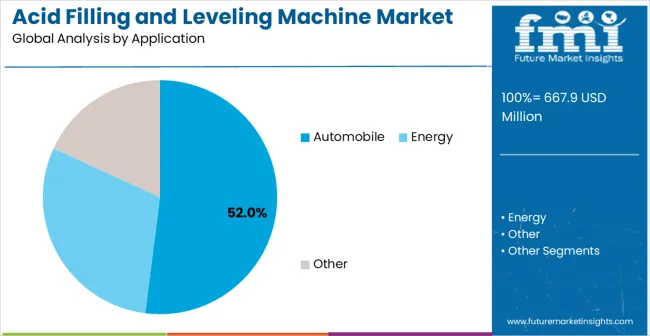

Leading Application in Acid Filling and Leveling Machine Market: Automobile (52.0%)

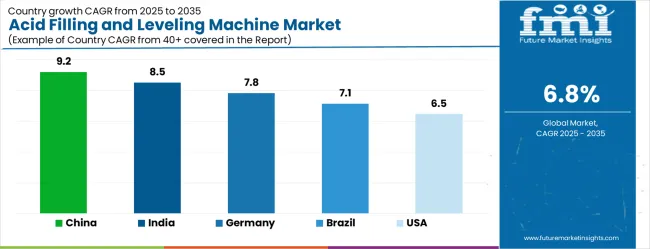

Key Growth Regions in Acid Filling and Leveling Machine Market: China, India, and Germany

Top Key Players in Acid Filling and Leveling Machine Market: Digatron Power Electronics, COSLIGHT, TBS Engineering, Bitrode Corporation, Wirtz Manufacturing, MAC Engineering & Equipment, Shandong Time High-Tech, Hadi Equipment, Shenzhen Haoneng Technology, Kshama Equipments, Zesar, Batek Makina, Manz AG, MACCOR, Kaizen Technology

Over the forecast period, the market is expected to see steady adoption across various sectors due to its ability to meet the rising need for high precision in filling and leveling. In particular, the pharmaceutical sector’s focus on ensuring the correct dosage and formulation is likely to drive significant demand for these machines. The rising investments in automation also fuel the market growth, as companies seek to reduce labor costs while improving operational reliability. Furthermore, the expansion of the food and beverage industry, particularly in areas requiring large-scale, high-speed production, is contributing to the growing need for acid filling and leveling solutions. These machines offer a critical solution for maintaining product integrity and improving manufacturing throughput, which explains the expected upward trajectory of the market through 2035.

Acid Filling and Leveling Machine Market Key Takeaways

Metric

Value

Market Value (2025)

USD 667.9 million

Market Forecast Value (2035)

USD 1,289.6 million

Forecast CAGR (2025-2035)

6.8%

The acid filling and leveling machine market contributes about 6% to the overall filling machinery market, with its specialized role in accurately filling and leveling chemical products in various industries. Within the packaging machinery market, it holds roughly 8%, driven by the increasing need for precise packaging in sectors such as chemicals and pharmaceuticals. In the chemical processing equipment market, the market share is about 7%, as these machines are essential for safely handling and processing hazardous materials.

The industrial automation market holds a 5% share, reflecting its use in automated production lines for enhanced efficiency and safety. In the pharmaceutical packaging market, acid filling and leveling machines account for approximately 4% of the market share, primarily due to their use in the filling and leveling of pharmaceutical liquids.

Why is the Acid Filling and Leveling Machine Market Growing?

Market expansion is being supported by the rapid advancement of electric vehicle manufacturing across developing economies and the corresponding need for automated battery production systems for precision acid filling in lead-acid battery manufacturing processes. Modern battery production operations require precise electrolyte management and level control to ensure optimal battery performance and quality standards. The superior accuracy and consistency characteristics of acid filling and leveling machines make them essential equipment in demanding battery manufacturing environments where product quality is critical.

The growing emphasis on production automation and quality control is driving demand for advanced filling and leveling machine technologies from certified manufacturers with proven track records of reliability and precision. Battery manufacturers are increasingly investing in automated systems that offer enhanced accuracy and reduced manual intervention over traditional filling methods. Industry standards and quality requirements are establishing performance benchmarks that favor precision-engineered acid filling and leveling solutions with advanced control capabilities.

Segmental Analysis

The market is segmented by automation level, application, and region. By automation level, the market is divided into manual acid filling machine, semi-automatic acid filling machine, and fully automatic acid filling and leveling machine configurations. Based on application, the market is categorized into automobile, energy, and other applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

By Automation Level, Fully Automatic Acid Filling and Leveling Machine Segment Accounts for 48% Market Share

Fully automatic acid filling and leveling machine configurations are projected to account for 48% of the acid filling and leveling machine market in 2025. This leading share is supported by the increasing demand for production efficiency and consistency in battery manufacturing applications and growing requirements for reduced manual intervention. Fully automatic machines provide superior precision and throughput capabilities, making them the preferred choice for automotive battery production, large-scale energy storage manufacturing, and high-volume battery applications. The segment benefits from technological advancements that have improved the control systems and reliability of fully automatic filling machines while reducing operational complexity and maintenance requirements.

Modern fully automatic acid filling and leveling machines incorporate advanced sensor systems, precision pumps, and sophisticated control algorithms that enable consistent filling accuracy and automated quality monitoring. These innovations have significantly improved battery production quality while reducing total cost of ownership through enhanced efficiency and elimination of human error in filling processes. The automotive and energy storage sectors particularly drive demand for fully automatic solutions, as these industries require absolute precision to maintain battery quality and comply with stringent performance standards.

Additionally, the industrial battery manufacturing sector increasingly adopts fully automatic systems to achieve production scalability and meet international quality certifications. Operational efficiency requirements and labor cost initiatives further accelerate market adoption, as fully automatic systems provide enhanced productivity while reducing dependency on skilled operators and manual processes.

By Application, Automobile Segment Accounts for 52% Market Share

Automobile applications are expected to represent 52% of acid filling and leveling machine demand in 2025. This substantial share reflects the critical role of lead-acid batteries in automotive applications and the need for reliable filling systems capable of meeting automotive quality and performance requirements in vehicle battery production. Automotive battery manufacturers require effective and precise filling machines for starter batteries, auxiliary power systems, and hybrid vehicle applications. The segment benefits from ongoing electric and hybrid vehicle production growth in developing countries and increasing automotive battery quality requirements demanding enhanced filling systems in automotive battery manufacturing facilities.

Automotive battery applications demand exceptional filling precision and consistency to ensure battery performance and reliability. These applications require machines capable of handling various battery sizes, electrolyte formulations, and production volumes while maintaining consistent quality throughout the manufacturing process. The growing emphasis on automotive battery standards, particularly in electric and hybrid vehicle applications, drives consistent demand for high-performance acid filling and leveling solutions. Emerging automotive markets in Asia-Pacific, Latin America, and European regions contribute significantly to market growth as automotive manufacturers invest in modern battery production technologies to improve vehicle reliability and market competitiveness.

Additionally, the trend toward automotive electrification and advanced battery systems creates opportunities for specialized filling machines equipped with enhanced precision capabilities and compatibility with next-generation battery technologies. The segment also benefits from increasing automotive production volumes and battery replacement market demand driven by growing vehicle populations and battery service requirements.

What are the Drivers, Restraints, and Key Trends of the Acid Filling and Leveling Machine Market?

The acid filling and leveling machine market is advancing rapidly due to increasing battery production automation and growing recognition of precision manufacturing technology importance. However, the market faces challenges including high equipment costs, need for specialized technical expertise, and varying filling requirements across different battery applications. Standardization efforts and certification programs continue to influence machine quality and market development patterns.

Integration of Industry 4.0 and Smart Manufacturing Technologies

The growing deployment of IoT-enabled monitoring systems and digital control interfaces is enabling real-time production optimization and predictive maintenance capabilities in acid filling and leveling machine installations. Smart sensors and automated quality control systems provide continuous monitoring of filling parameters while optimizing production efficiency and extending equipment service life. These technologies are particularly valuable for large battery manufacturing facilities that require comprehensive production monitoring and minimal unplanned downtime.

Development of Precision Control and Environmental Compliance Solutions

Modern acid filling machine manufacturers are incorporating advanced flow control systems and environmental safety features that improve filling accuracy while ensuring operator safety and regulatory compliance through sophisticated ventilation and containment technologies. Integration of precision metering systems and advanced safety protocols enables superior filling consistency and significant environmental protection compared to traditional manual filling methods. Advanced manufacturing processes and quality control systems also support development of more reliable and environmentally compliant acid filling machines for demanding battery production environments.

Analysis of Acid Filling and Leveling Machine Market by Key Country

Country

CAGR (2025-2035)

China

9.2%

India

8.5%

Germany

7.8%

Brazil

7.1%

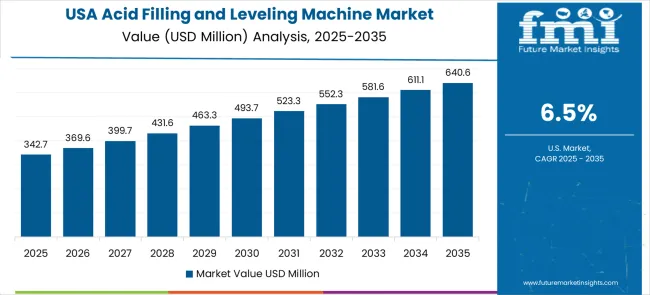

United States

6.5%

United Kingdom

5.8%

Japan

5.1%

The acid filling and leveling machine market is growing rapidly, with China leading at a 9.2% CAGR through 2035, driven by massive electric vehicle production expansion, battery manufacturing growth, and automotive industry development. India follows at 8.5%, supported by rising automotive investments and increasing adoption of automated battery manufacturing technologies in automotive and energy storage applications. Germany records strong growth at 7.8%, emphasizing precision engineering, automotive excellence, and advanced manufacturing technology capabilities. Brazil grows steadily at 7.1%, integrating acid filling and leveling machines into expanding automotive production and energy infrastructure facilities. The United States shows moderate growth at 6.5%, focusing on battery technology innovation and manufacturing automation improvements. The United Kingdom maintains steady expansion at 5.8%, supported by automotive manufacturing programs. Japan demonstrates stable growth at 5.1%, emphasizing technological innovation and manufacturing precision.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

Opportunity Analysis for Acid Filling and Leveling Machine Market in China

The acid filling and leveling machine market in China is projected to exhibit the highest growth rate with a CAGR of 9.2% through 2035, driven by rapid electric vehicle production expansion and massive battery manufacturing development programs across automotive sectors. The country’s growing automotive battery production and expanding energy storage industries are creating significant demand for automated filling and leveling systems. Major battery manufacturers are establishing comprehensive production installations to support large-scale electric vehicle battery production operations and meet national electrification standards.

China’s automotive sector continues expanding rapidly, with major investments in electric vehicle production, battery manufacturing, and automotive electrification programs. The country’s position as a global electric vehicle manufacturing hub drives substantial demand for reliable acid filling solutions that ensure battery quality and production efficiency across diverse automotive applications.

Electric vehicle production modernization programs are supporting widespread adoption of advanced acid filling technologies across battery manufacturing facilities, driving demand for automated and high-precision production solutions.

Automotive electrification and battery manufacturing expansion initiatives are creating substantial opportunities for specialized filling machine applications in demanding production environments requiring consistent quality standards.

Demand Assessment for Acid Filling and Leveling Machine Market in India

The acid filling and leveling machine market in India is expanding at a CAGR of 8.5%, supported by increasing automotive investments across manufacturing sectors and growing adoption of automated battery manufacturing technologies in automotive and energy storage applications. The country’s expanding automotive industry is driving demand for specialized filling systems capable of handling diverse battery production and quality requirements. Battery manufacturers are investing in advanced filling technologies to improve production efficiency and comply with automotive quality standards.

India’s automotive development initiatives and battery manufacturing expansion create significant opportunities for acid filling machine applications. The country’s growing electric vehicle market drives demand for automotive batteries and energy storage systems, requiring reliable filling solutions to maintain production quality and operational efficiency.

Automotive sector growth and battery manufacturing expansion are creating opportunities for specialized filling machine applications across diverse production facilities requiring reliable battery manufacturing solutions.

Government automotive programs and electrification initiatives are driving investments in advanced filling systems for battery production throughout major automotive manufacturing regions.

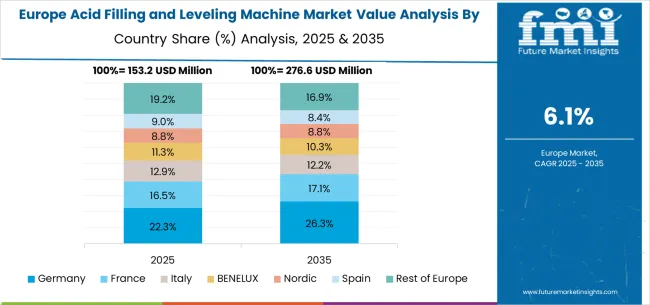

Sales Forecast for Acid Filling and Leveling Machine Market in Germany

The acid filling and leveling machine market in Germany is projected to grow at a CAGR of 7.8%, supported by the country’s emphasis on automotive excellence and advanced manufacturing technology capabilities. German automotive facilities are implementing high-performance filling systems that meet stringent quality standards and production reliability requirements. The market is characterized by focus on technological innovation, precision engineering, and compliance with comprehensive automotive regulations.

Germany’s advanced automotive sector and manufacturing excellence capabilities drive demand for high-quality filling machine solutions. The country’s emphasis on automotive innovation, technological advancement, and manufacturing precision creates opportunities for advanced filling technologies that meet demanding automotive specifications.

Automotive industry investments are prioritizing advanced filling machine technologies that demonstrate superior performance and reliability while meeting German automotive quality and environmental standards.

Manufacturing excellence programs and automotive innovation initiatives are driving adoption of high-performance filling systems that support optimal production conditions and enhanced battery reliability.

In-depth Review of Acid Filling and Leveling Machine Market in Brazil

The acid filling and leveling machine market in Brazil is growing at a CAGR of 7.1%, driven by expanding automotive production and increasing energy infrastructure development across industrial sectors. The country’s growing automotive industry is investing in advanced filling systems to improve battery production quality and performance in competitive market conditions. Manufacturing facilities are adopting modern filling technologies to support growing automotive requirements and quality standards.

Brazil’s expanding automotive infrastructure and industrial development create substantial opportunities for filling machine applications. The country’s growing vehicle production market and energy expansion drive investments in battery manufacturing solutions that enhance production competitiveness and operational efficiency.

Automotive production expansion and industrial development are facilitating adoption of reliable filling machine systems capable of consistent performance in diverse manufacturing environments.

Industrial modernization programs and automotive enhancement initiatives are increasing demand for advanced filling solutions that meet evolving production standards and quality requirements.

Growth Outlook for Acid Filling and Leveling Machine Market in United States

The acid filling and leveling machine market in the United States is expanding at a CAGR of 6.5%, driven by ongoing battery technology innovation and increasing emphasis on manufacturing automation solutions. Battery manufacturing facilities are upgrading existing production systems with advanced technologies that provide improved performance and enhanced production capabilities. The market benefits from replacement demand and facility modernization programs across multiple battery manufacturing sectors.

The United States market emphasizes battery innovation, technology advancement, and manufacturing improvement in filling machine applications. Advanced research and development activities drive the adoption of next-generation filling technologies that offer superior performance and production reliability.

Battery manufacturing facility upgrades and innovation programs are driving demand for advanced filling machine systems that offer superior production precision and enhanced manufacturing capabilities.

Technology development initiatives and manufacturing advancement mandates are supporting adoption of innovative filling technologies that demonstrate compliance with quality standards and production requirements.

Market Penetration Analysis for Acid Filling and Leveling Machine Market in United Kingdom

The acid filling and leveling machine market in the United Kingdom is projected to grow at a CAGR of 5.8%, supported by ongoing automotive manufacturing programs and battery production facility upgrades. Manufacturing operators are investing in reliable filling systems that provide consistent performance and meet regulatory compliance requirements. The market is characterized by focus on production reliability, quality compliance, and manufacturing efficiency across diverse automotive applications.

The United Kingdom’s focus on automotive manufacturing and battery production drives demand for high-performance filling machine solutions. The country’s emphasis on production quality, manufacturing efficiency, and automotive compliance creates opportunities for advanced filling technologies.

Automotive manufacturing initiatives and battery production enhancement programs are supporting adoption of advanced filling machine systems that meet contemporary quality and production standards.

Manufacturing modernization programs and efficiency improvement initiatives are creating demand for specialized filling applications that provide reliable performance and manufacturing excellence.

Strategic Insights for Acid Filling and Leveling Machine Market in Japan

The acid filling and leveling machine market in Japan is expanding at a CAGR of 5.1%, driven by the country’s emphasis on technological innovation and manufacturing excellence in battery production applications. Japanese manufacturers are developing advanced filling machine technologies that incorporate precision engineering and efficiency-optimized design principles. The market benefits from focus on quality, reliability, and continuous improvement in manufacturing technology performance.

Japan’s technological leadership and manufacturing expertise drive the development of advanced filling machine solutions. The country’s emphasis on innovation, quality control, and production optimization creates opportunities for cutting-edge filling technologies that set industry standards.

Manufacturing excellence programs and technological innovation initiatives are driving development of advanced filling machine systems that demonstrate superior performance and production reliability.

Battery technology and precision manufacturing programs are supporting adoption of precision-engineered filling solutions that optimize production conditions and enhance manufacturing quality.

Competitive Landscape of Acid Filling and Leveling Machine Market

The acid filling and leveling machine market is defined by competition among established industrial equipment manufacturers, specialized battery production equipment companies, and emerging automation solution providers. Companies are investing in advanced control technologies, precision engineering, standardized safety systems, and technical support capabilities to deliver reliable, accurate, and cost-effective acid filling and leveling solutions. Strategic partnerships, technological advancement, and geographic expansion are central to strengthening product portfolios and market presence.

Digatron Power Electronics, operating globally, offers comprehensive acid filling and leveling solutions with focus on precision control, reliability, and technical support services. COSLIGHT, multinational manufacturer, provides advanced battery manufacturing systems with emphasis on production efficiency and automation integration capabilities. TBS Engineering, specialized provider, delivers innovative filling machine solutions for battery applications with focus on accuracy and durability. Bitrode Corporation offers comprehensive battery testing and production technologies with standardized procedures and technical service support.

Wirtz Manufacturing provides industrial filling systems with emphasis on automotive applications and technical expertise. MAC Engineering & Equipment, Shandong Time High-Tech deliver specialized filling solutions with focus on precision manufacturing. Hadi Equipment, Shenzhen Haoneng Technology offer comprehensive filling and leveling technologies for demanding battery production environments with established manufacturing and service capabilities.

Kshama Equipments, Zesar, Batek Makina, Manz AG, MACCOR, Kaizen Technology provide advanced filling systems with regional manufacturing capabilities, battery industry expertise, and specialized knowledge across production automation and battery manufacturing sectors.

Global Acid Filling and Leveling Machine Market – Stakeholder Contribution Framework

The acid filling and leveling machine market underpins battery manufacturing excellence, automotive electrification advancement, production automation optimization, and energy storage solutions. With safety mandates, stricter quality requirements, and demand for automated production systems, the sector must balance cost competitiveness, precision reliability, and environmental compliance. Coordinated contributions from governments, industry bodies, OEMs/technology integrators, suppliers, and investors will accelerate the transition toward automation-optimized, environmentally sustainable, and technologically advanced acid filling and leveling systems.

How Governments Could Spur Market Growth and Adoption

Electric Vehicle Manufacturing Incentives: Provide subsidies or tax credits for manufacturers upgrading to advanced or automated acid filling and leveling machine solutions.

Battery Quality Standards: Enforce stringent battery manufacturing quality, safety compliance, and production efficiency standards, boosting demand in automotive, energy storage, and industrial battery sectors.

Automotive Electrification Programs: Embed advanced filling technologies into electric vehicle manufacturing initiatives, battery production projects, and automotive modernization enhancement programs.

Trade Facilitation: Lower tariffs for importing precision equipment and automation components while supporting local exports of battery manufacturing systems.

Innovation Mandates: Recognize automated and precision filling solutions within national automotive competitiveness and electrification frameworks.

How Industry Bodies Could Support Market Development

Standardization & Certification: Develop harmonized guidelines for filling accuracy, safety benchmarks, and battery manufacturing quality testing procedures.

Training & Workforce Development: Create curricula for machine operation, maintenance techniques, and advanced filling technologies to reduce skill shortages.

Global Recognition: Position regional manufacturers as leaders in precision-engineered and automated acid filling and leveling solutions.

Policy Advocacy: Engage with automotive regulators to shape favorable procurement policies and inclusion of filling machines in battery manufacturing standards.

How OEMs and Technology Integrators Could Strengthen the Ecosystem

Technology Integration: Embed IoT monitoring, automated controls, and quality assurance into acid filling and leveling systems.

Partnerships: Collaborate with battery manufacturers, automotive companies, and energy storage providers to design application-specific filling configurations.

Product Innovation: Advance precision control systems, safety technologies, and enhanced automation capabilities.

Comprehensive Solutions: Bundle filling machines with complete battery production lines, offering end-to-end manufacturing effectiveness.

How Suppliers Could Navigate the Market Evolution

Advanced Components: Provide precision pumps, control systems, and safety-enhancing components to extend filling accuracy and operational reliability.

Localized Manufacturing: Establish regional production facilities to reduce logistics costs and improve battery manufacturing market access.

Portfolio Diversification: Expand into specialty filling components, automation solutions, and battery production technologies.

Customer Engagement: Build trust via equipment traceability, performance guarantees, and comprehensive manufacturing service excellence.

How Investors and Financial Enablers Could Unlock Value

Infrastructure Financing: Fund filling machine manufacturing facilities, regional service centers, and production plants in high-growth battery manufacturing markets.

Innovation Finance: Channel automotive-linked capital toward automated and precision filling machine solutions.

M&A and Consolidation: Back cross-border mergers to integrate fragmented regional players into scalable global battery equipment suppliers.

Technology Funding: Support startups developing advanced automation technologies, IoT integration platforms, or specialized filling applications.

Risk Management Tools: Provide insurance and hedging products against component cost volatility and automotive market fluctuation risks.

Key Players in the Acid Filling and Leveling Machine Market

Digatron Power Electronics

COSLIGHT

TBS Engineering

Bitrode Corporation

Wirtz Manufacturing

MAC Engineering & Equipment

Shandong Time High-Tech

Hadi Equipment

Shenzhen Haoneng Technology

Kshama Equipments

Zesar

Batek Makina

Manz AG

MACCOR

Kaizen Technology

Scope of the Report

Item

Value

Quantitative Units

USD 667.9 million

Automation Level

Manual Acid Filling Machine, Semi-Automatic Acid Filling Machine, Fully Automatic Acid Filling and Leveling Machine

Application

Automobile, Energy, Other

Regions Covered

North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa

Country Covered

United States, Germany, India, China, United Kingdom, Japan, Brazil, and other 40+ countries

Key Companies Profiled

Digatron Power Electronics, COSLIGHT, TBS Engineering, Bitrode Corporation, Wirtz Manufacturing, MAC Engineering & Equipment, Shandong Time High-Tech, Hadi Equipment, Shenzhen Haoneng Technology, Kshama Equipments, Zesar, Batek Makina, Manz AG, MACCOR, Kaizen Technology

Additional Attributes

Dollar sales by automation level and application segments, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established manufacturers and emerging suppliers, buyer preferences for fully-automated versus manual filling systems, integration with Industry 4.0 and battery manufacturing technologies, innovations in control systems and safety technologies for enhanced precision and environmental compliance, and adoption of smart filling solutions with embedded monitoring and quality control capabilities for improved production efficiency.