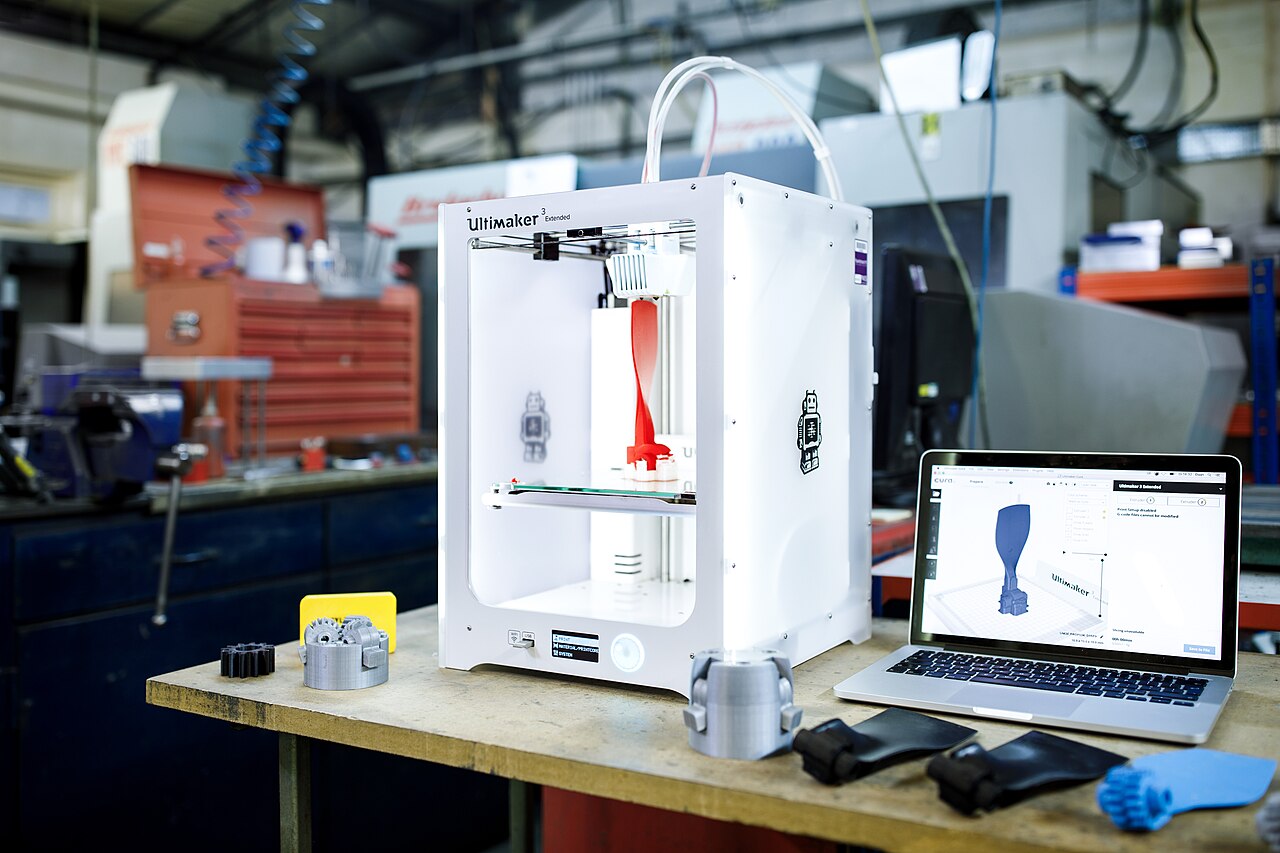

Scientists at McGill University in Quebec say they have developed a flexible 3D printer designed to help rebuild injured vocal cords. Credit: Svitlana Lozova – CC BY-SA 4.0 via Wikimedia commons.

Scientists at McGill University in Quebec say they have developed a minimally invasive, flexible 3D printer designed to help rebuild injured vocal cords, a technique the team says could reduce scarring after throat surgery and improve voice outcomes.

The device, described by the research team as a minimally invasive in-situ bioprinter (MIISB), uses a 2.7-millimeter flexible endoscopic printhead that fits through the working channel of standard suspension laryngoscopy, the common approach used in phonosurgery.

Surgeons would control nozzle position in real time to reconstruct the natural geometry of the vocal fold body by depositing a regenerative hydrogel into defects left after removal of polyps, lesions, or other pathologies.

Voice disorders affect an estimated 3% to 9% of the global population, and post-surgical fibrosis, scarring that stiffens the vocal folds and degrades voice quality, occurs in roughly 5% to 18% of patients, the paper notes. Current preventative approaches rely on percutaneous hydrogel injections, which the authors say lack the spatial precision needed for some superficial lesions.

The team says their 3D Printer achieved minimal error margins for potential vocal cord repairs

The McGill team reports that their system achieved a mean nozzle-positioning error of 1.33 millimeters (0.052 inches), repeatability better than 0.2 mm (0.008 inches), and position drift under 0.8 mm (0.031 inches) within a 20 mm (0.787-inch) workspace.

The smallest consistent line width the printer produced was 1.2 mm (0.047 inches). The researchers demonstrated manual printing of 20-mm (0.787-inch) constructs on flat surfaces and reconstruction of simulated vocal-fold defects, including a sulcus and cavity models, in an ex vivo surgical setup.

The research used a dopamine-grafted hyaluronic acid–silk fibroin hydrogel developed by the group for vocal-fold regeneration. That material, the team says, combines adhesive and mechanical properties tailored to the vocal fold’s high-frequency vibrations and is designed to promote healthy tissue repair while degrading over time to reduce scarring.

The Minimally Invasive In-Situ Bioprinter (MIISB) developed by the McGill team combines a cable-driven soft robotic printhead housed in a 3.2 mm (0.126-inch) stainless-steel tube and an actuator unit mounted outside the surgeon’s workspace. A data-driven kinematic model translates surgeon commands into coordinated cable actuations to bend and position the nozzle; hydrogel extrusion is controlled by a pressurized syringe and solenoid valve. The device is intended to integrate with existing operating-room microscopes and laryngoscopy equipment.

McGill researchers say the development is not yet ready for human trials

Researchers caution that the work remains preclinical. The study identifies several limitations that will need addressing before human trials, including printhead stiffness, current low stiffness improves safety but magnifies vibration, variation between fabricated printheads, and challenges tied to manual control, such as over-extrusion. The authors say improvements to actuation hardware, nozzle geometry, and automated control algorithms are planned, and that in-vivo animal studies to assess tissue integration and long-term safety are underway.

The team also notes broader potential for the approach, suggesting the technique could be adapted to other internal tissues that would benefit from accurate, minimally invasive hydrogel deposition.

If MIISB proves safe and effective in future animal and clinical testing, the authors say it could offer surgeons a new tool to precisely rebuild vocal-fold structure and reduce the number of patients who suffer persistent voice problems after surgery.