Taiwanese tech entrepreneur Thomas Yen (顏伯勳) turned fiction into reality after being inspired by the maneuverability of a car in the Hollywood science-fiction film I, Robot.

“There were these futuristic cars with ball-shaped wheels that I thought were really cool,” Yen, 25, said of the Audi RSQ concept car used in the movie, which was equipped with spheres instead of wheels.

The founder of satellite solutions company Tensor Tech said that while sphere-based motor technology had existed for more than 20 years, it was limited to the academic world.

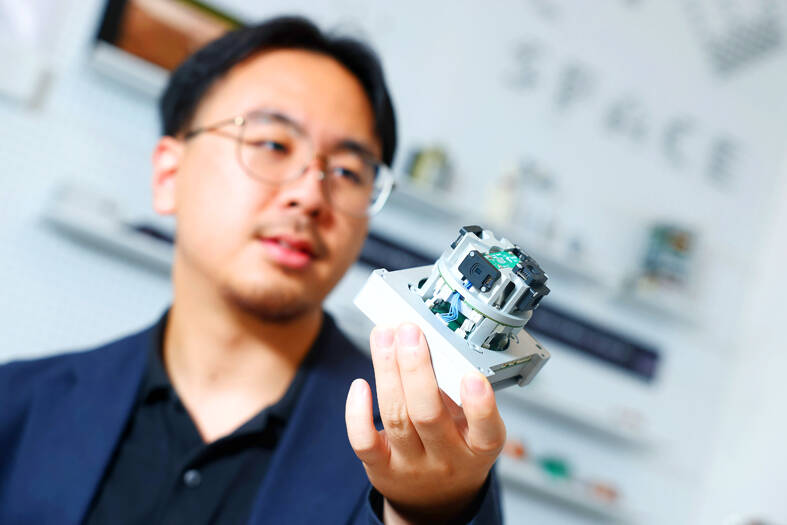

Photo: CNA

His company became the first start-up to engineer the motors for commercial use in space satellites.

From a young age, Yen said he knew his passion was in technology, but Taiwan’s education system was too rigid for what he wanted to accomplish, and as a result, his family homeschooled him for high school, enabling him to concentrate on engineering.

It was during those years that the early concept of his company’s flagship product took shape.

Through the support of a tech personnel cultivation project initiated by the Ministry of Education, he and a friend were given permission in high school to use the Department of Electrical Engineering lab at National Cheng Kung University, Yen said.

As the university works with the Taiwan Space Agency, the teenagers were introduced to single-axis motors, commonly used to control a satellite’s attitude, or its orientation in relation to a center such as the Earth or the sun.

Yen started to think of ways to replace single-axis motors in satellites with spherical ones by using one of his favorite fictional technologies.

“Engineers enjoy challenges and creating new objects, and that was how I got started,” he said.

Yen was accepted into the Department of Electrical Engineering at National Taiwan University, but dropped out and started his own company in 2019.

A singular spherical motor enables a satellite to smoothly adjust its attitude toward Earth in different directions, while single-axis motors used in most traditional satellites require three motors to rotate hardware in space, Yen said.

Not only do spherical motors allow for better and smoother maneuverability of a satellite, they also drastically cut costs, he said.

In addition to providing satellites with spherical attitude, the single unit also enables better electricity allocation, as the hardware only has to focus on one motor rather than three, facilitating the redirection of power to other parts of a satellite, he said.

However, the most alluring aspect of a single-motor system is that it lightens the weight of a payload, he added.

Customers often pay more than NT$1 million (US$33,306) per kilogram to rocket companies such as Elon Musk’s Space Exploration Technologies Corp (SpaceX) for payloads sent into space, Yen said.

That means Tensor Tech could save customers NT$1 million for every kilogram of weight eliminated from a satellite, he said.

SpaceX carries the satellites of his customers into space every season, he said.

The Taiwanese start-up’s first satellite with a spherical motor was launched by SpaceX in January 2022. The motor ran until the satellite disconnected a year later.

Although the company initially only made spherical motors for small satellites, it gradually created complimentary control systems to pair with the motors, Yen said.

Tensor Tech also aims to make large-scale spherical motors that can be used to adjust the attitude of big satellites, he said.

From his perspective, the most valuable asset the company possesses is the power of its engineering, he said, adding that he hopes his company will continue to uphold engineering excellence as its core value.