How the Cadillac Formula 1® Team makes a brake duct

2026-02-02

By: Chris Perkins, writer and editor, GM News

A Formula 1® car can slow down from 200-plus miles per hour at well over four times the force of gravity. Doing so generates incredible heat as the brake system converts the kinetic energy of the wheel rotating into thermal energy. Brake discs glow bright orange as they regularly reach in excess of 1,300 degrees Fahrenheit. To help manage that heat, Formula 1® cars have ducts to vent cooling air to all the components that make up the braking system and designing one is not easy.

The front brake ducts are the focus of Episode 5 of GM’s docuseries on the Cadillac Formula 1® team, What Makes Fast. “We want to make sure [the braking system] doesn’t melt itself, and that it doesn’t melt all the things adjacent to it,” explains GM Motorsports Aerodynamics Surface Designer Chad Vermeulen.

Sounds simple, right? The reality is anything but.

The Fédération Internationale de l’Automobile (FIA) sets out the rules for Formula 1®, and there are very specific regulations regarding brake ducts. “We are operating in a space that has a lot of restraints and constrictions,” explains Nick Schaut, design engineer with GM Motorsports.

Aerodynamicists lead off the effort here, making sure that the brake duct fits both FIA rules and the team’s cooling requirements. Then, it’s off to design and manufacturing to turn sketches and computer models into reality, adhering as close to the original design as possible. On the way there, the team 3D-prints prototype parts to prove in physical space what computer simulation predicts.

All of that work is just for one version of a front brake duct. That front brake duct is also one of thousands of parts that make up a Formula 1® car. Designing all those components is the challenge the Cadillac Formula 1® Team faces in creating a chassis from scratch.

“If you hear anything about brake ducts, it’s probably because there’s an issue,” Schaut says. It’s his job – and the job of over 500 of his teammates – to make sure that each part of the car works as designed.

When the Cadillac Formula 1® Team’s car hits the grid in Australia in March, fans will see GM’s vast motorsports experience in design, simulation, prototyping, and aerodynamics at play. If the team has done its job well, thousands of components will all work in harmony.

Including the brake ducts.

Watch Episode 5 below.

By: Chris Perkins, writer and editor, GM News

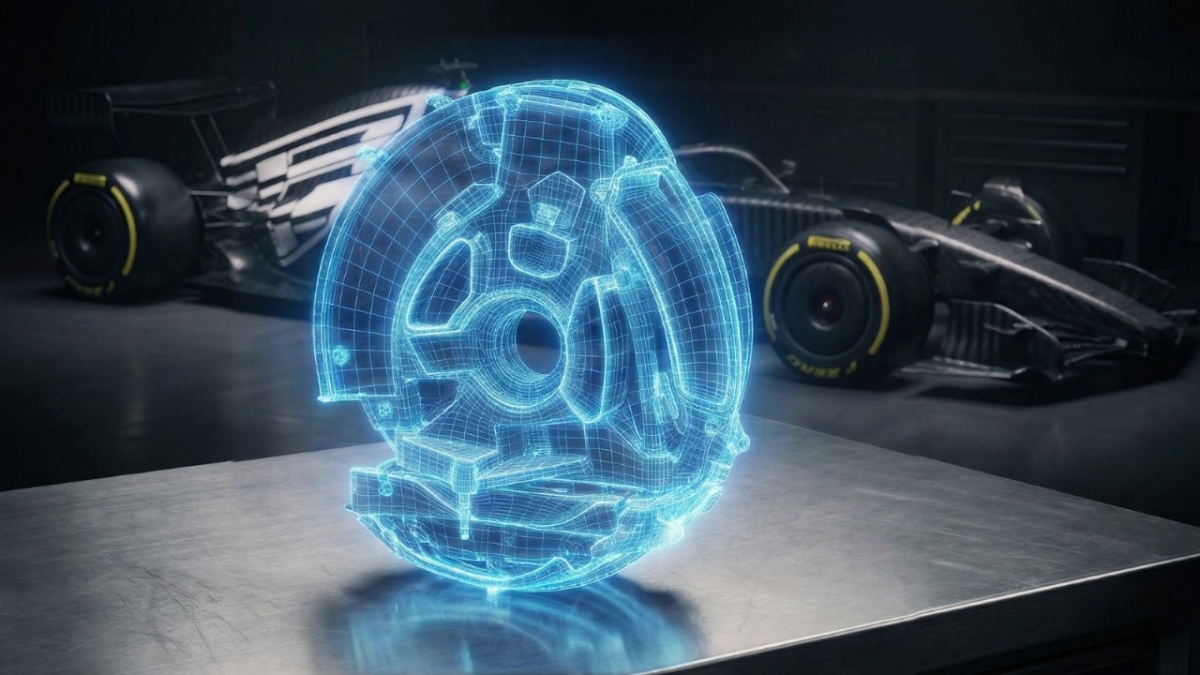

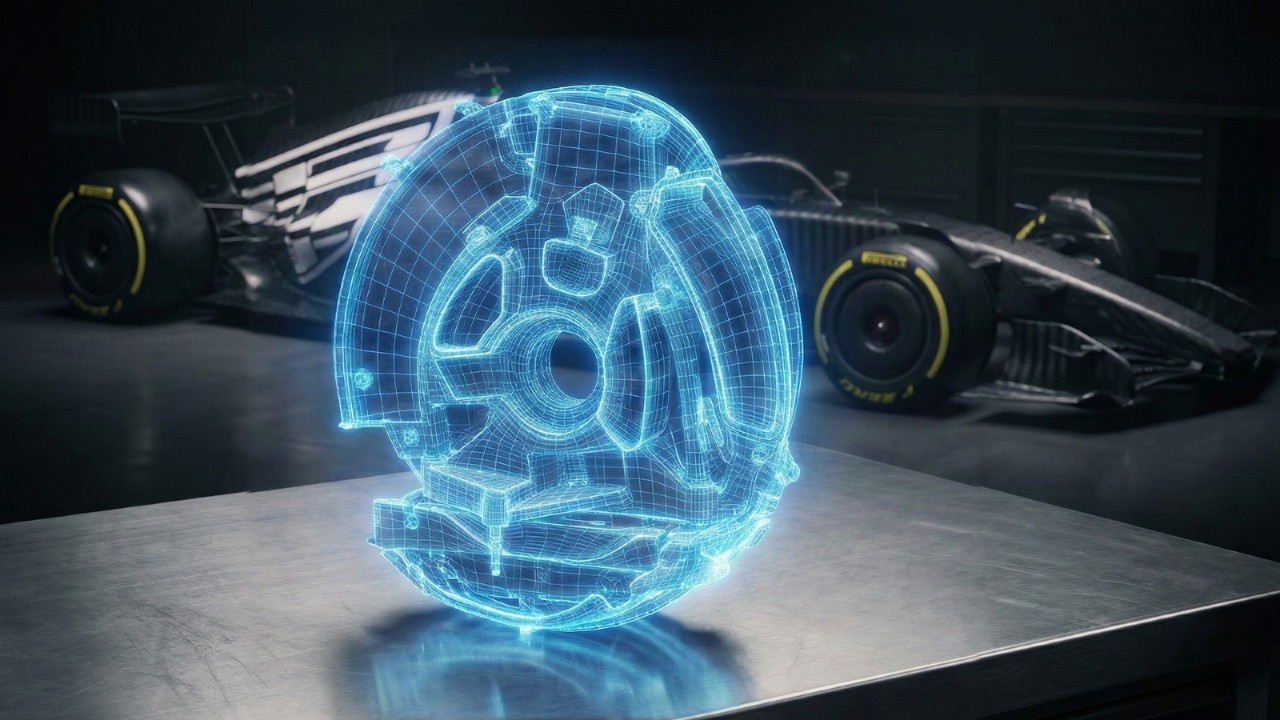

F1 brake duct rendering

A Formula 1® car can slow down from 200-plus miles per hour at well over four times the force of gravity. Doing so generates incredible heat as the brake system converts the kinetic energy of the wheel rotating into thermal energy. Brake discs glow bright orange as they regularly reach in excess of 1,300 degrees Fahrenheit. To help manage that heat, Formula 1® cars have ducts to vent cooling air to all the components that make up the braking system and designing one is not easy.

The front brake ducts are the focus of Episode 5 of GM’s docuseries on the Cadillac Formula 1® team, What Makes Fast. “We want to make sure [the braking system] doesn’t melt itself, and that it doesn’t melt all the things adjacent to it,” explains GM Motorsports Aerodynamics Surface Designer Chad Vermeulen.

Sounds simple, right? The reality is anything but.

The Fédération Internationale de l’Automobile (FIA) sets out the rules for Formula 1®, and there are very specific regulations regarding brake ducts. “We are operating in a space that has a lot of restraints and constrictions,” explains Nick Schaut, design engineer with GM Motorsports.

Aerodynamicists lead off the effort here, making sure that the brake duct fits both FIA rules and the team’s cooling requirements. Then, it’s off to design and manufacturing to turn sketches and computer models into reality, adhering as close to the original design as possible. On the way there, the team 3D-prints prototype parts to prove in physical space what computer simulation predicts.

All of that work is just for one version of a front brake duct. That front brake duct is also one of thousands of parts that make up a Formula 1® car. Designing all those components is the challenge the Cadillac Formula 1® Team faces in creating a chassis from scratch.

“If you hear anything about brake ducts, it’s probably because there’s an issue,” Schaut says. It’s his job – and the job of over 500 of his teammates – to make sure that each part of the car works as designed.

When the Cadillac Formula 1® Team’s car hits the grid in Australia in March, fans will see GM’s vast motorsports experience in design, simulation, prototyping, and aerodynamics at play. If the team has done its job well, thousands of components will all work in harmony.

Including the brake ducts.

Watch Episode 5 below.