The FlexArray solar array uses thin-film membranes to deploy solar cells, delivering high power-to-volume ratios.

MMA Space has developed a low-cost solar array capable of generating tens of kilowatts that can be manufactured in a fraction of the time of conventional solar arrays. The new FlexArray Solar Array system utilizes proprietary thin-film membranes to mount and deploy solar cells, resulting very high power-to-volume ratios.

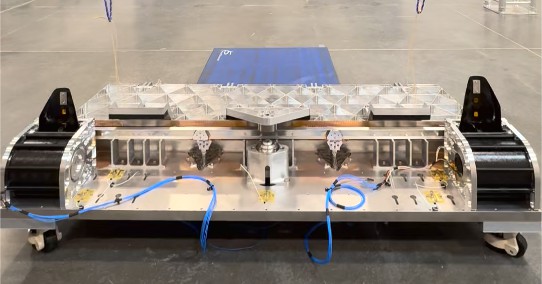

FlexArray Standard SmallSat class solar array deployed front.

FlexArray Standard SmallSat class solar array deployed front.

As satellite power requirements grow, there is increasing demand for solutions that deliver more power at lower cost. Access to traditional solar cells has also become more limited and expensive in recent years. To address this, MMA developed a solar array designed to lower cost per watt and reduce lead times. MMA Space has long produced rigid-panel solar arrays optimized for peak power within a compact stowed envelope. The FlexArray design builds on this experience, using efficient packing methods, materials, and processes to support larger platforms.

The FlexArray Standard SmallSat class solar array in its stowed state.

The FlexArray Standard SmallSat class solar array in its stowed state.

This new approach comes at a fraction of the cost of traditional solar arrays especially when populated with more readily available, next-generation silicon solar cells. MMA combats the lower efficiency of the silicon solar cells by creating larger deployed areas. The FlexArray system, however, is cell agnostic and can leverage any traditional solar cells desired. FlexArray can be produced at high volumes due to the simplicity of its design and is tailored for constellation platforms.

MMA developed the FlexArray under Internal Research + Development funding, and leverages core subsystems that have been previously flight proven on other MMA deployable solutions to ensure high system reliability. Furthermore, the Flexarray has undergone rigorous ground qualification testing, including thermal and vibration, raising the entire system to TRL6.

For more information, visit mma.space.