The Founder of BatteryIQ has revealed that the business has hit a funding round target that will help bring to fruition a technology that aims to enhance the battery management software supply chain.

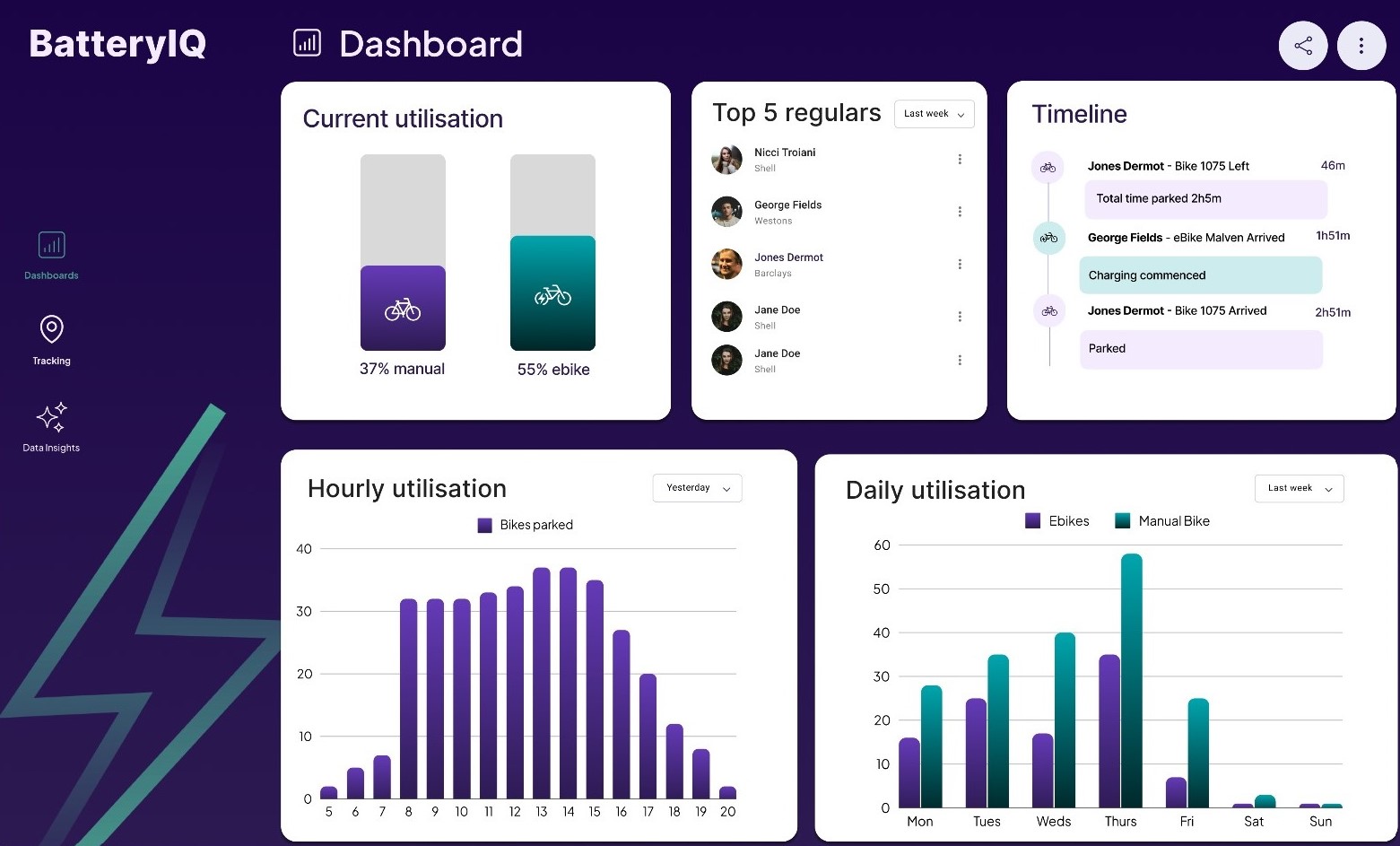

We first reported on BatteryIQ’s business back in November last year, with the offshoot to Boost Bikes taking its learnings from producing electrical systems for electric bikes, then deploying into batteries a real-time software that can monitor the current status of a battery. This information is fed back via a software dashboard to any interested party.

This means that buildings management concerned about the quality of e-bikes on site could have information to hand the moment an e-bike enters the premises, and, in the rare instance of a thermal escalation, an alarm would alert via the software likely before the first physical signs of thermal runaway occur. The goal is essentially to confirm that all batteries on site are UL2271 compliant.

This product’s idea has its foundations in the noise around electric bike battery safety and the often misrepresented narrative around the technology. While lab tests have shown the vast majority of electric bike batteries to be incredibly hard to provoke a thermal runaway from, that has not stopped a narrative developing around e-bike battery safety that has since seen them banned from Transport for London services, with some landlords and even larger buildings and bike shops. The backdrop to this is an insurance underwriting industry that has bought into the poor press and thus put the brakes on coverage for some businesses.

It works across a multitude of metrics, the chipset being able to detect increased humidity, among other suspicious cell behaviours, yet likely in advance of major issues. The AI-driven algorithm also live records the voltage of every cell in a battery, plus the temperature.

BatteryIQ brings forward a circuit board that it now aims to get into the supply chain, the Founder Nick Bailey telling us ‘Given that the technology now exists and is a tiny additional cost, why wouldn’t all battery manufacturers consider implementing it?’

The firm is not a battery manufacturer and so the chip would have to be fitted at source by e-bike battery brands. Nick says it will be available to brands that can demonstrate their quality control and production standards as being up to scratch. The technology won’t remain here on earth, so says Nick, aerospace customers are also invited to get in touch.

BatteryIQ has early interest from a handful of e-bike and scooter brands, so expect to see the technology branch out soon. The technology, it is said, could help pre-warn brands to batches of batteries that may have defects and be subject to a recall, before real problems emerge and cost the business.

Initially, Nick says that the funding round will go toward more product testing, recruitment of sales leadership and outreach to brands and manufacturers.