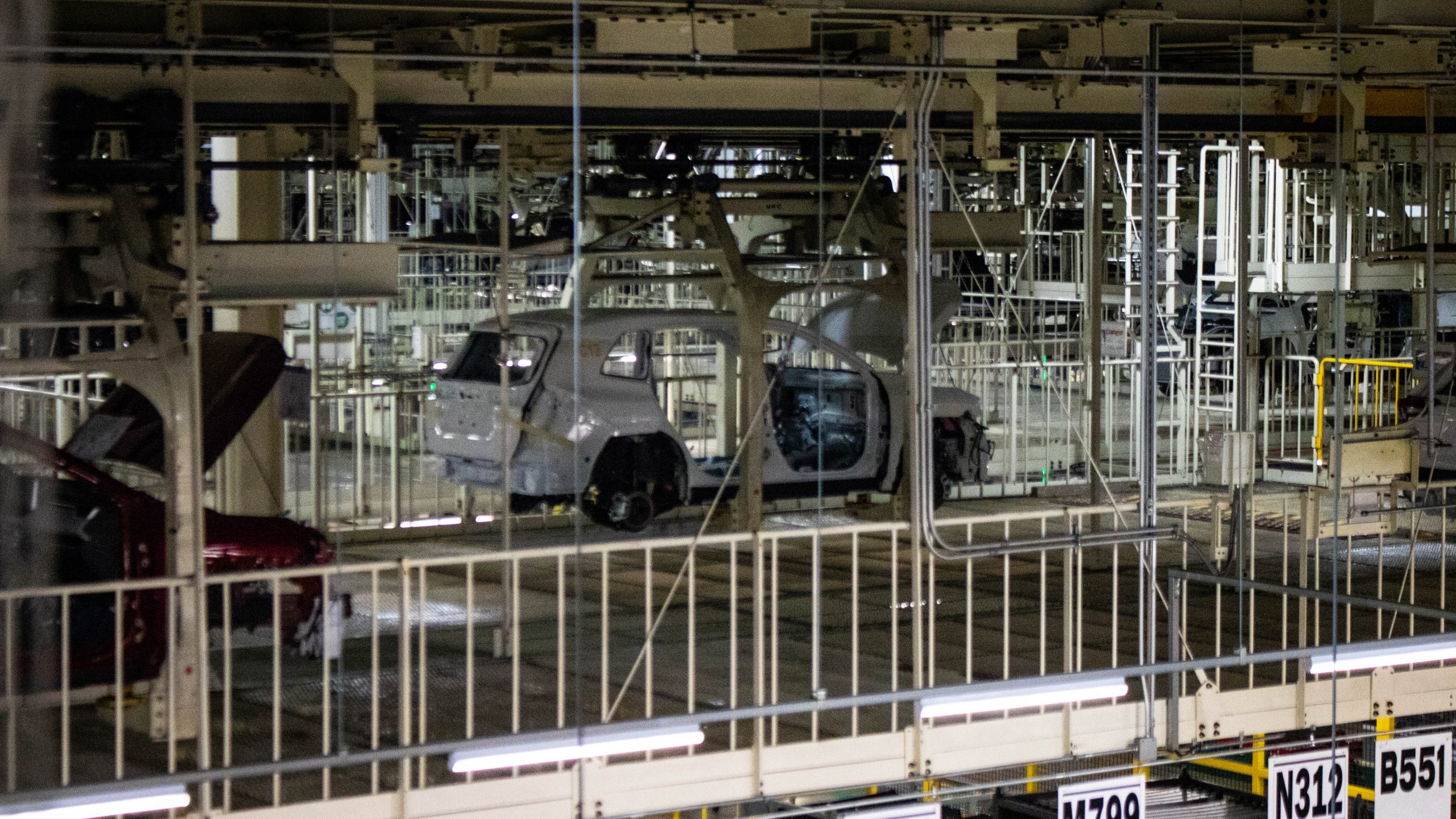

The new 2026 Toyota RAV4 is just about here, and while developing a new generation of the world’s best-selling car is a gargantuan undertaking, the process of actually assembling the thing is arguably even more impressive. See, Toyota Motor Manufacturing Canada’s West plant in Woodstock, Ont. is running at full-tilt with maxed-out overtime. Demand for the outgoing RAV4 remains so strong, you can’t just shut down a major assembly plant willy-nilly. So how do you gear up for a new RAV4 while still quenching the public’s thirst? By building two different generations of RAV4 on the same line at the same time, of course.

If someone tells you that the 2026 RAV4 is all-new, feel free to correct them. It’s really a heavy evolution of the previous model. While 60 percent of its parts aren’t shared with the old RAV4, it still rides on the same platform and wheelbase, meaning we’re not looking at a complete retool here. Sure, it requires new dies in stamping and new molds in the plastics department that makes stuff like the bumpers and the dashboards, but a certain level of commonality means Toyota is running a production pilot concurrent to fifth-generation RAV4 production. This means that a handful of new RAV4s and a whole bunch of old RAV4s run down the same assembly line, with machines like crane systems and pallet systems permitting workers to take these pre-production 2026 models, stop them, pull them aside, inspect them, and then put them back on the assembly line to continue both its path and employee training.

![]()

![]()

While the short-lived third-generation RAV4 EV was built in Woodstock, Toyota Motor Manufacturing Canada’s West Plant previously hadn’t assembled the RAV4 Hybrid at all. Now it’s gearing up for the all-hybrid sixth-generation model, and that includes assembling battery packs. Not plug-in hybrid packs, but the 1.1 kWh packs found in all non-plug-in models. It’s a big change, so here’s an overview of how that crucial process works.

Photo credit: Thomas Hundal

Photo credit: Thomas Hundal

It all starts in Toyota’s North Carolina battery plant, where individual cells are assembled into the modules that make up a battery pack. Those modules are then shipped all the way up to Woodstock, Ont. where five new bay doors have been installed in the side of the plant just to keep modules flowing into the facility. At the same time, stamping takes care of pressing out the actual battery pack casing, and the components that make up individual battery packs are shuttled from holding locations to the battery pack assembly line using in-plant autonomous vehicles.

Photo credit: Thomas Hundal

Photo credit: Thomas Hundal

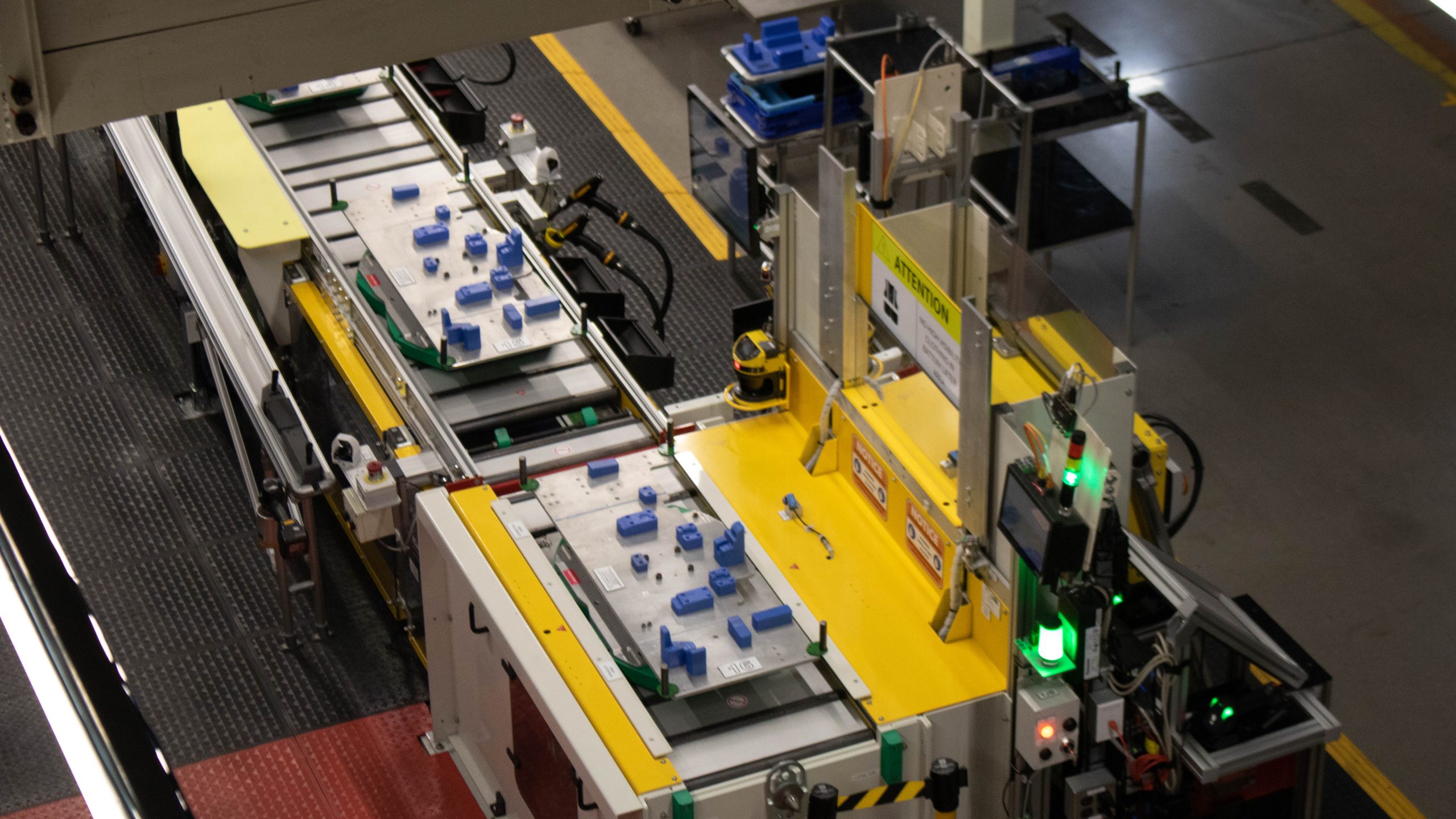

Perhaps the most surprising thing about the battery pack assembly line itself is how relatively small it is. In terms of total footprint, I’ve seen larger apartments, which says a lot about the efficiency of the line. Considering a new RAV4 rolls off the line at TMMC West every 58 seconds, the battery pack assembly line runs slightly faster just for the sake of margin, and it features some cool worker-led innovation. Obviously, you’re going to want to isolate battery terminals when building high-voltage packs, and custom tools to do just that were rapid-prototyped using 3D printing, then injection-molded for durability once an ideal fit was achieved. Speciality equipment like this makes building packs such a snap, Toyota even has time to take them for a ride.

Photo credit: Thomas Hundal

Photo credit: Thomas Hundal

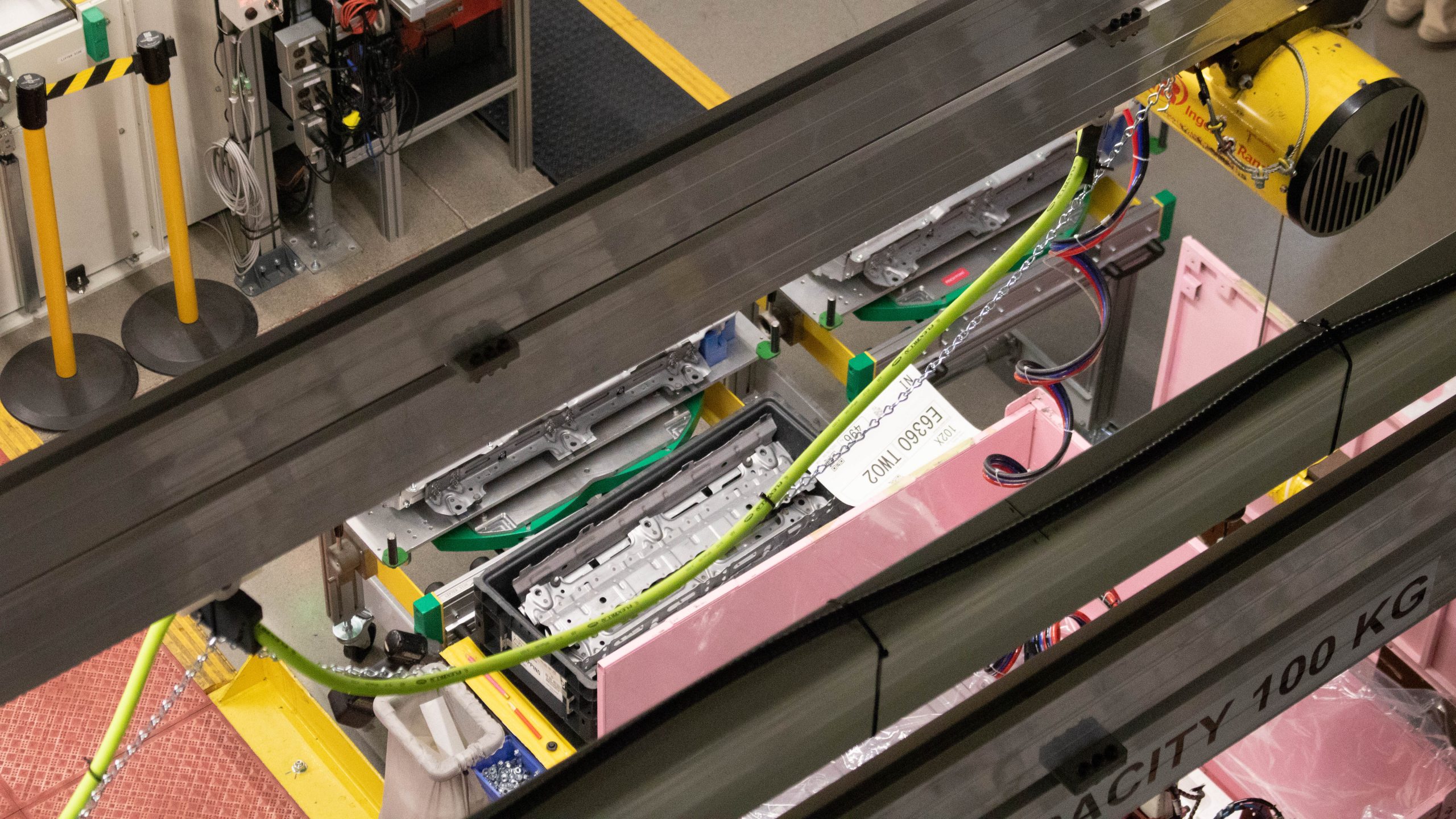

See, between the battery pack assembly line and the vehicle assembly line sits a massive passageway for parts and people that simply can’t be interrupted by battery pack cross-traffic every minute or so. As a result, each battery pack rides an elevator up to a conveyor that runs well above the passageway on the ground floor below, ending at another elevator that lowers each battery pack to the vehicle assembly line level. Oh, and if you think that’s cool, wait until you hear about documentation.

It’s no secret that assembling a modern vehicle requires huge amounts of documentation to maintain quality. We’re talking petabytes of data from scans of spot weld accuracy and penetration to torque values of installed components to which batches of which parts from which suppliers made it into which vehicles. Not only does keep quality up, it can also make identifying and repairing problems easier after a car’s rolled off the assembly line.

Because Toyota collects so much data when building the new RAV4, each hybrid battery pack sports a QR code that leads to a database, telling a franchise dealer or third-party repairer when a particular pack was made, what sort of cells are inside, when the cells were made, and it sounds like Toyota’s even thinking of sharing torque values from the pack assembly process in this database.

Photo credit: Thomas Hundal

Photo credit: Thomas Hundal

Speaking of data, Toyota’s North American assembly plants now all feature vision-based artificial intelligence, not to replace trained safety and quality control professionals, but to augment them. The goal is to spot potential issues humans might miss, and then leave it up to humans to actually make improvements. For instance, cameras and image recognition are great for spotting quality control concerns that might not be visible at a glance, then humans assess what the computers have found, solve any problems on the spot, and implement new processes for improved quality control. It seems like a logical evolution of Jidoka, which Toyota describes as automation with a human touch, and so long as it continues with the mindset that a computer can never be held accountable or be responsible for decisions the same way a human can, it seems like a responsible way of using machine learning.

While we’re on the subject of automation, it’s worth noting that there are some tasks that would just be grunt work for humans. Manually installing a spare tire on a vehicle every minute or so is a real pain in the neck, so Toyota’s invested in developing a robot that automates the entire process, from placing the spare tire in its well to closing the hatch properly with different techniques depending on if a vehicle’s equipped with a manual or power liftgate. Once assembly’s done, it’s off to quality control where each new RAV4 gets checked over under the bright lights, put on a chassis dynamometer, and any last little issues can be corrected.

Photo credit: Thomas Hundal

Photo credit: Thomas Hundal

By trialling production of the new RAV4 while cranking out the old one, Toyota’s able to dramatically shorten the time required for a full changeover. In the case of TMMC West, it’ll happen mostly over the winter break, meaning the actual downtime involved is rather small. Shortly after the holidays, things will get busy again. After all, TMMC West is running full-tilt, and it’s expected to keep that pace when full-scale 2026 RAV4 production starts.

Top graphic image: Thomas Hundal