Germany has taken another major step toward realizing scalable quantum computers with the launch of SmaraQ, a collaborative research initiative that integrates quantum optics directly onto a chip. The project, driven by QUDORA Technologies GmbH, AMO GmbH, and Fraunhofer IAF, aims to replace bulky optical assemblies with compact, chip-based systems that promise to make ion-trap quantum computers more efficient and scalable.

Reinventing optical control for ion-trap systems

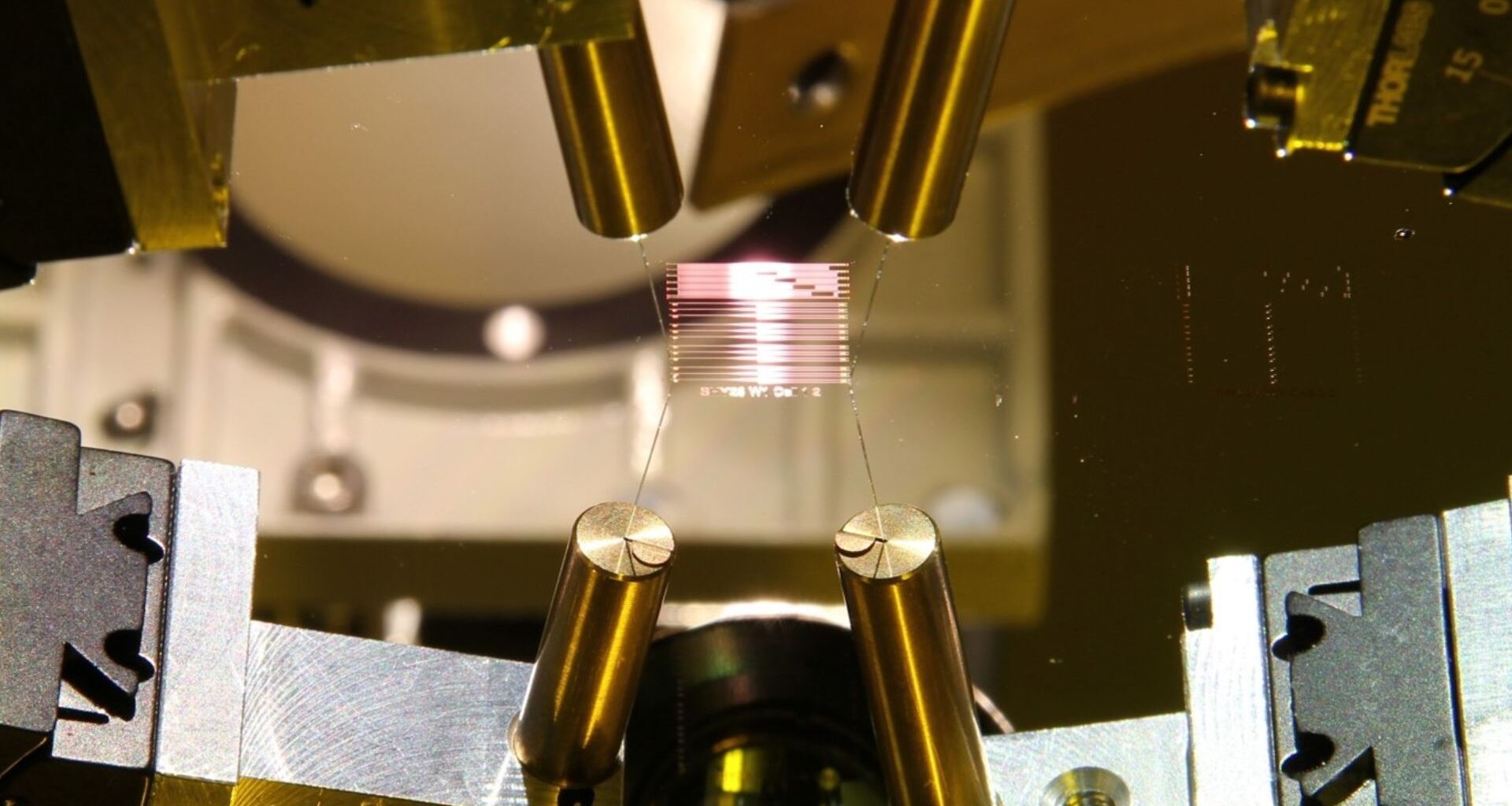

At the heart of SmaraQ lies a breakthrough in photonic integration. Traditional ion-trap quantum computers rely on intricate arrangements of mirrors and lenses to direct laser beams for qubit control, a setup that becomes increasingly complex as systems grow larger. Each ion, acting as a qubit, must be precisely addressed with laser light for operations like initialization and cooling. Maintaining that precision across hundreds or thousands of qubits has remained a fundamental challenge for scaling up.

SmaraQ addresses this issue by developing ultraviolet (UV) waveguides and photonic components composed of aluminum nitride (AlN) and aluminum oxide (Al₂O₃). These materials are being used to fabricate on-chip waveguides that can channel light directly to the qubits with nanometer-scale precision. The approach eliminates the need for large free-space optics, drastically reducing system size and improving reliability.

“On-chip integration represents the path forward for ion-trap quantum computing,” said Dr. Maik Scheller, Head of Photonics at QUDORA, in a press release. “We are engineering waveguide structures at the nanometer scale, ten thousand times thinner than a human hair, that deliver light with pinpoint precision exactly where our ion qubits demand it.”

This integration not only enhances optical stability but also facilitates the mass production of quantum processors using established semiconductor fabrication methods, a crucial step toward the broader deployment of quantum computing technology.

A collaboration rooted in complementary expertise

SmaraQ brings together three key partners, each contributing distinct technical expertise. QUDORA Technologies, serving as the project coordinator, is responsible for integrating the photonic systems into its trapped-ion quantum computing architecture and driving commercialization beyond the project’s duration. The company’s proprietary NFQC (Next-Generation Field Quantum Computing) technology is known for achieving high qubit coherence and precision control, setting benchmarks in trapped-ion systems.

Fraunhofer IAF contributes its specialization in materials science by developing epitaxial thin-film AlN wafers of exceptional quality, which serve as the foundation for the photonic components. Meanwhile, AMO GmbH applies its advanced nanofabrication capabilities to create and pattern these components onto chips using cutting-edge lithography. Together, these efforts form a Germany-based supply chain for critical quantum computing materials and components, a strategic advantage for maintaining technological independence.

The project’s name, SmaraQ, is inspired by the Smaragdkolibri, also known as the Blue-tailed Emerald Hummingbird, which is renowned for its precision and ability to perceive ultraviolet light. The analogy captures the project’s focus on miniaturization and control at microscopic scales, essential qualities in the world of quantum technology.

Toward sustainable and sovereign quantum technologies

Running from 2025 to 2028, SmaraQ is funded by Germany’s Federal Ministry of Research, Technology, and Space (BMFTR) under a program supporting enabling technologies in quantum research. The initiative is part of a broader national effort to strengthen Europe’s leadership in quantum computing and secure critical supply chains within the continent.

By focusing on scalable, integrated optical technologies, SmaraQ addresses one of the most significant bottlenecks in ion-trap quantum computing. Maintaining precise optical access as qubit numbers increase. If successful, the project could establish a blueprint for industrial-scale quantum processor manufacturing, bridging the gap between laboratory prototypes and commercially viable systems.