Ferrari 2026 and flexible suspensions represent one of the most important technical directions that the Scuderia has chosen to pursue in Formula 1 for the upcoming regulatory cycle. This is a parameter on which the team has invested extensive development work over many months, aiming to give the car a very specific characteristic capable of delivering superior competitiveness in managing vehicle dynamics and, as a direct consequence, optimising tyre behaviour under all track conditions. It is therefore worth examining in detail how this solution functions and what Ferrari is ultimately aiming to achieve through this advanced engineering approach. The aim is not only to improve lap times but also to give the car a balanced behaviour that allows its drivers to exploit tyres fully, in both qualifying and race conditions, on every type of circuit that Formula 1 will visit during the 2026 season.

Ferrari has a clearly defined objective for the upcoming 2026 regulations: to firmly establish itself at the very top of the pinnacle of global motorsport, a goal that represents the absolute priority for the team. As highlighted by detailed analysis of the Formula 1 season that has just concluded, ensuring a correct and efficient interface between the tyres and the track surface through the optimisation of suspension dynamics has proven to be one of the most challenging aspects for Ferrari in recent years. Achieving consistency in tyre performance, maintaining mechanical grip, and ensuring stable aerodynamic behaviour have all remained significant hurdles for the team, especially when attempting to maintain optimal performance across different circuits with varying track layouts, surfaces, and weather conditions.

This is precisely why, well before the conclusion of the 2025 Formula 1 season, specifically on 10 December, our editorial team published a detailed article focusing on the central role that tyre management will play in the Ferrari 2026 project. The technical director, Loic Serra, working on his first full-scale Formula 1 project with the Prancing Horse, has made it a priority to provide the new car with the maximum capacity to exploit the full potential of the tyres under all circumstances. This is considered one of the primary objectives of Ferrari’s entire vehicle design philosophy for the new season, underlining the importance of integrating suspension and tyre dynamics. Loic Serra’s approach reflects a deep understanding of how the interaction between suspension, aerodynamics, and tyre behaviour can influence race pace, overtaking potential, and overall competitiveness.

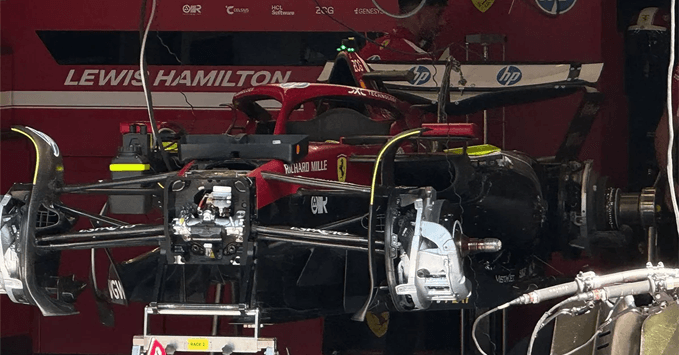

The creation and development process of the Ferrari 2026 car has been meticulously structured to allow Lewis Hamilton and Charles Leclerc to compete on fully equal terms with the other leading Formula 1 teams, as Red Bull, Mercedes, and McLaren are expected to once again be the Maranello team’s main rivals. Every single detail of the vehicle has been carefully considered, with a high level of attention paid to maximising the potential of each individual component. Only through this kind of meticulous engineering and detailed focus is it possible to reach the level of excellence demanded by the pinnacle of motorsport. At this stage, it is possible to provide additional insights into this highly technical approach, which involves not only computational simulations and wind tunnel testing but also extensive on-track trials and data collection with both Lewis Hamilton and Charles Leclerc to validate every design choice.

Clear indications are emerging from Maranello regarding the technical direction that Ferrari has taken with its 2026 car. One of the most prominent areas of focus concerns the flexibility of the front suspension wishbones, an aspect which involves several technical departments working together within the team, from structural engineering to aerodynamics and materials science. The suspension assembly of a modern Formula 1 car is typically designed to be extremely stiff, ensuring that the aerodynamic platform of the car remains as stable as possible in all running conditions, including high-speed corners, braking zones, and changes in track gradient. Maintaining this balance between stiffness for aerodynamic efficiency and controlled flexibility for tyre management is one of the most delicate challenges for engineers.

As analysed over recent weeks, the 2026 cars will continue to use suspension layouts that limit floor movement. Although their role is less dominant than in the era of purely ground-effect wing cars, the floor still remains strategically important for generating aerodynamic downforce, particularly when negotiating high-speed corners and maintaining tyre temperature consistency. The flexing of suspension arms is, of course, regulated under the 2026 Formula 1 technical rules, but the FIA’s required checks remain purely static in nature, creating opportunities for intelligent engineering solutions within these constraints. Ferrari’s engineers have explored materials and carbon fibre layering techniques that allow the front suspension wishbones to flex dynamically under specific load conditions without breaching the regulations during static tests, an approach that requires deep expertise in both materials engineering and vehicle dynamics.

Successfully passing these FIA static tests confirms the legality and compliance of the solution. The flexibility is achieved through an intelligent layering of carbon fibre skins, with fibres arranged in a manner that gives anisotropic properties to the final component. In this way, the wishbone can pass all FIA compliance checks while still allowing deformation when applied loads act in directions different from those defined by the regulations during official scrutineering procedures. This approach enables Ferrari to manage dynamic changes in suspension geometry, particularly camber, which has a direct influence on tyre contact patch, grip levels, and overall stability, giving both Lewis Hamilton and Charles Leclerc more confidence during aggressive cornering or under braking.

From an engineering perspective, allowing controlled flexing of the first link of the upper wishbone triangle inevitably requires a targeted approach to the overall stiffness of the suspension system. Achieving this effect under dynamic, real-world track conditions is extremely complex, as the suspension system must remain effective on-track while staying fully compliant with the regulations established by the FIA, the governing body of Formula 1. Every decision regarding material choice, layer orientation, and suspension geometry must balance structural integrity with performance gains, creating a system that is both reliable and optimised for dynamic performance.

The objective of this regulated flexing on Ferrari’s front suspension is to develop a system capable of producing a dynamic variation in camber recovery at specific speeds and under specific load conditions. When the link flexes under defined loads, its apparent length is reduced, generating a controlled camber change with significant positive effects on the overall vehicle dynamics of the Formula 1 car, improving both cornering performance and tyre longevity. This dynamic camber adjustment allows Ferrari to maintain optimal tyre contact, reducing excessive wear while increasing mechanical grip and downforce generation, which is particularly crucial on circuits with high-speed turns or variable surface conditions.

Controlling these parameters allows the suspension to be tuned in direct response to tyre behaviour, optimising both grip and stability in specific operating conditions, whether in fast sweepers or tight technical corners. Defining the correct camber angle is always a compromise between multiple, often conflicting objectives, including aerodynamic efficiency, tyre degradation management, and mechanical grip. The combination of targeted stiffness, anisotropic flexing of the suspension arms, and the management of variable loads represents a very delicate balance that requires high levels of precision and engineering insight. Ferrari’s engineering team has spent countless hours iterating on computer simulations, virtual modelling, and real track testing to ensure that both Lewis Hamilton and Charles Leclerc can fully exploit the car’s dynamic capabilities in qualifying and race conditions.

As is easy to understand in Formula 1, precision in defining the interaction of these suspension elements has a direct and measurable impact on on-track performance. To implement this solution, Ferrari has followed a carefully structured development plan, involving simulation, wind tunnel testing, and extensive track testing with Lewis Hamilton and Charles Leclerc. The Italian team believes that this approach can make a crucial difference between producing a car that is merely competitive and one that is consistently at the front of the grid, capable of fully exploiting the potential of the tyres in every race situation. This meticulous approach is essential in a sport where even a few hundredths of a second per lap can be decisive over a full race distance.

This engineering approach, despite its inherent complexity, demonstrates how the Ferrari 2026 project has pushed several technical concepts to their absolute limits. As always, while these insights provide a unique technical perspective, the final verdict will ultimately come from the performance on-track, which remains the only true judge of whether the extensive suspension-focused work undertaken by Ferrari in Maranello will deliver the expected performance improvements within a technical landscape set to feature an almost limitless series of innovations and refinements. The interaction between Lewis Hamilton, Charles Leclerc, and the car itself will provide the most accurate measure of the effectiveness of these advanced suspension solutions throughout the 2026 season, on circuits ranging from Monaco to Monza, and from Spa-Francorchamps to Singapore.

Dec 31, 2025Luca Marini

Let other Scuderia Fans know about us