In a major leap for adaptive robotics, researchers at the Korea Advanced Institute of Science and Technology (KAIST) have developed a programmable robotic sheet that can change shape, move, and grasp objects, all without mechanical hinges or external reconstruction.

The innovation could pave the way for next-generation robots that physically adapt to their environment in real time.

Led by Professors Kim Jeong and Park In-kyu of KAIST’s Department of Mechanical Engineering, the team unveiled what they call a “field-programmable robotic folding sheet.” The work combines physical artificial intelligence with software-controlled reprogrammability.

This approach offers solutions to a long-standing problem in robotics—creating systems that can change form based on task or environment without needing to be rebuilt or redesigned each time.

Folding without fixed hinges

Folding-based transformation has been a go-to strategy in robotics for years. It’s efficient, intuitive, and inspired by origami. But traditional systems rely on pre-designed hinges and fixed folding paths, limiting their flexibility and adaptability.

The KAIST team overcame this by designing a thin, flexible polymer sheet embedded with a dense network of metallic resistors.

These resistors act as both heaters and sensors.

When heated, the material bends; when cooled, it resets. This dual-function network allows the sheet to fold, monitor, and correct its movements without needing external sensors or actuators.

In contrast to earlier systems that required physical reconfiguration to switch tasks, this robotic sheet responds to software commands.

Users can reprogram the shape, fold positions, and directions on the fly using a simple interface.

The sheet then executes these commands autonomously, using real-time temperature feedback to maintain precision.

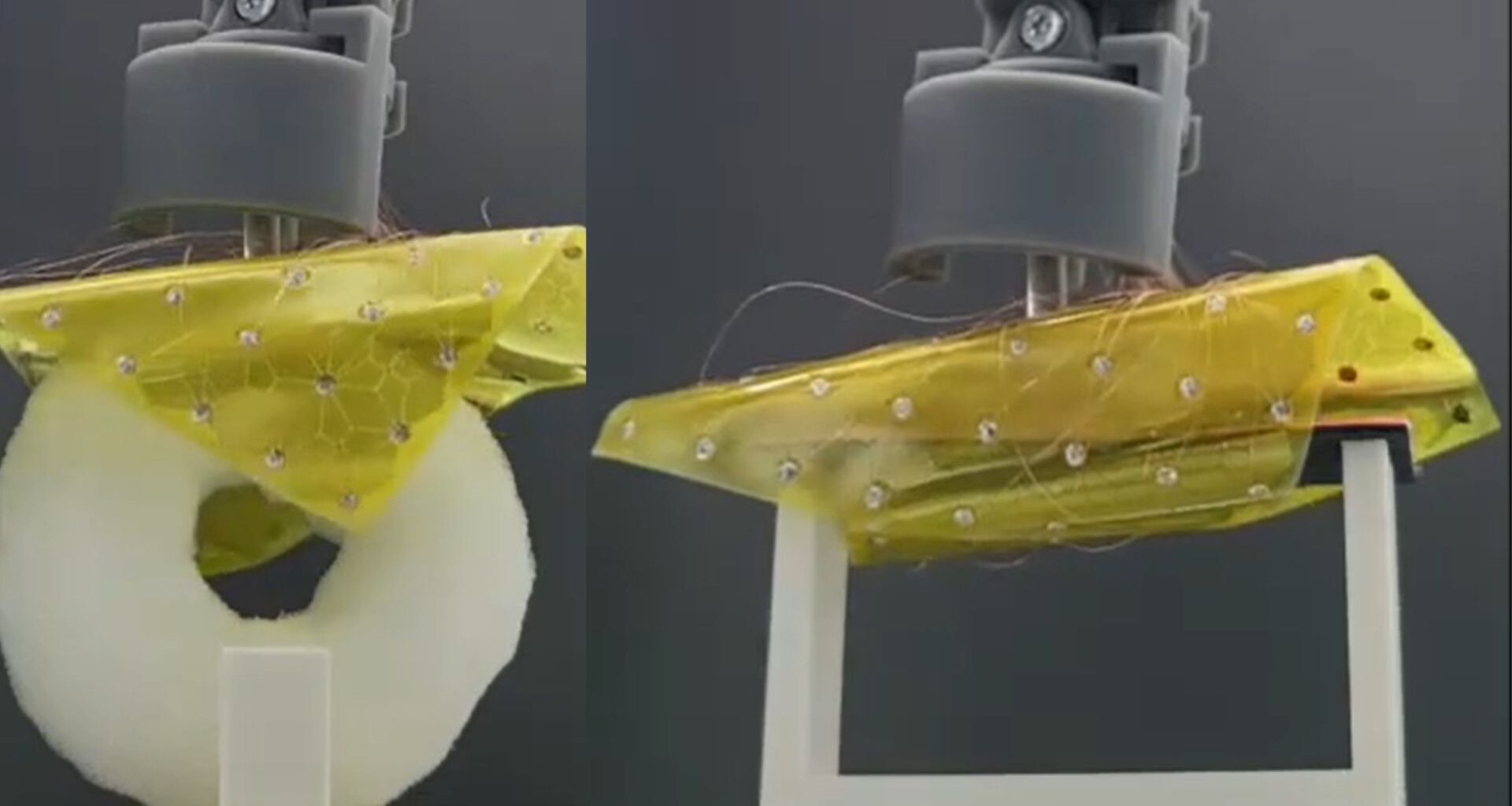

A 40 cm² prototype embedded with 308 resistor units demonstrated the technology’s potential.

The researchers programmed it to walk, crawl, and even grip objects like petri dishes and wooden sticks. It achieved folding angles between -87° and 109° and functioned across a wide temperature range of 30°C to 170°C.

AI-powered adaptability

To enhance performance, the system integrates genetic algorithms and deep neural networks.

These power the decision-making process behind the folding behavior, enabling adaptive responses to various inputs.

A closed-loop control system further refines the output by correcting for environmental changes, such as temperature fluctuations that usually impair heat-based systems.

The result is a material that not only morphs but thinks through its shape, what the researchers refer to as “morphological intelligence.”

In one test, the sheet served as a gripper that adjusted its hold based on an object’s form. In another, the same material crawled like a biological organism, mimicking natural motion.

“This research takes us one step closer to what we call ‘morphological intelligence,’ where the robot’s shape becomes part of its intelligence,” said Professor Kim.

The team plans to improve the sheet’s load-bearing capacity, speed up cooling times, and develop integrated electrodes without external wiring.

Long term, they aim to turn this into a deployable AI platform for disaster response, personalized medical devices, and even space exploration.

The National Research Foundation of Korea supported the research under the Ministry of Science and ICT.