A professor at Boise State University has succeeded in producing and commercializing a new plastic polymer that offers resilience and recyclability, opening up a pathway for closed-loop recycling.

Scott Phillips is a professor at the university’s Micron School of Materials Science and Engineering, and after 15 years of research, he managed to create a new plastic polymer that can be broken down into its original state for successful reuse, according to a Boise State University report.

“Modern plastic recycling processes often use heat and mechanical force to recycle an item, which ends up breaking some of the polymers, and as polymers get shorter, the mechanical properties — the strength, flexibility, recyclability, and so forth — of the resulting plastic that you want to make gets diminished,” Phillips said.

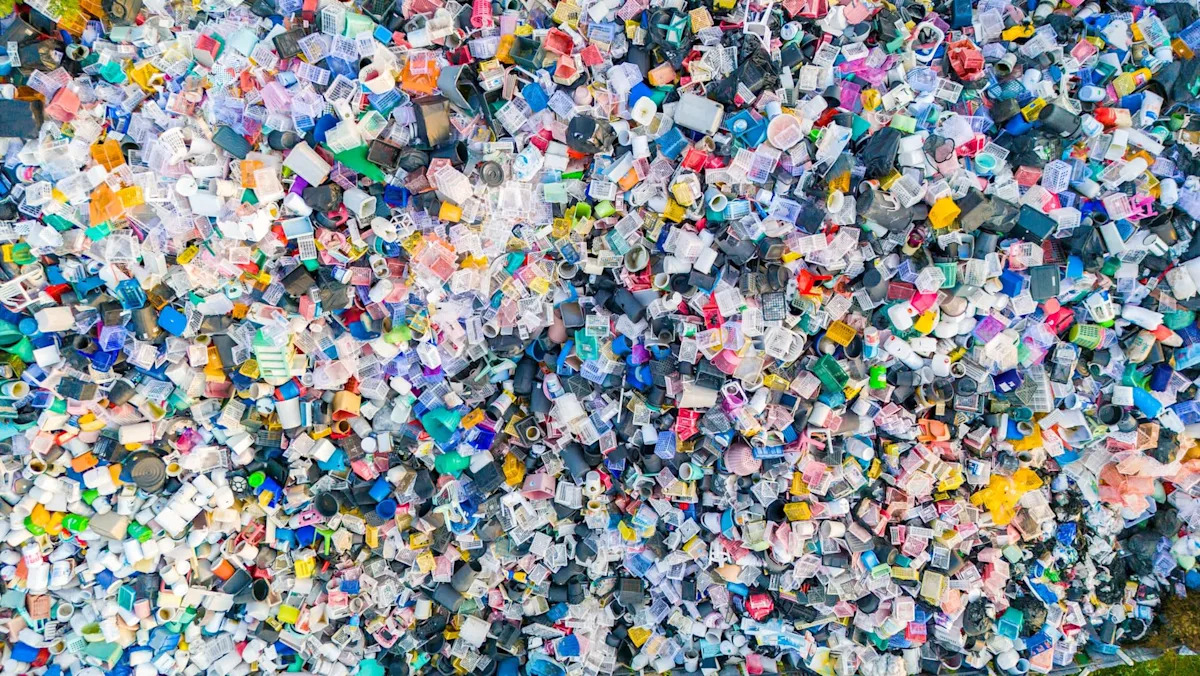

The world has a plastic problem. The World Economic Forum shared that more than 460 million metric tons of the stuff are produced every year. An estimated 20 million tons of that end up leaking into aquatic ecosystems, polluting lakes, rivers, and seas, especially those broken down into microplastic particles.

Recycling efforts to date have been underwhelming, with only about 9% of global plastic waste actually being recycled. About 46% of plastics end up in landfills, which are notorious for planet-warming methane pollution, while the other portions end up incinerated or as litter.

“We know that plastic is in our nature, in our oceans, and yes, even in our bodies … What is sure is that no one wants to live with the plastic pollution,” said Inger Andersen, executive director of the UN Environment Program, during a global discussion about plastic waste.

The polymer that Phillips invented is a stable polyacetal — or engineered thermoplastic — that, with the right processing, can be depolymerized and returned to its original state for reuse in manufacturing.

It has also remained solid and unreactive at room temperature in open air, where, historically, other plastics have shown degradation, the report explained.

In 2008, Professor Phillips started his own group to work on developing a special polymer that could open up a path for closed-loop recycling and potentially reduce the amount of plastic waste through more effective processes.

“I had never made a polymer in my life,” Phillips shared in the report. “People told me I was wasting my time, and that nobody was ever gonna change from polyethylenes (very common plastics), and that there was no need for this.”

When Nishad Dhopatkar, a senior researcher at advanced materials group Avery Dennison, discovered Phillips’ research at a 2019 conference, that all changed.

According to Boise State University’s report, the company licensed Phillips’ technology in 2025 and plans to use it to develop new materials and reduce waste in various markets, including packaging, eco-friendly graphics, and more.

There are plastic-free alternatives for consumers looking to do their part in reducing waste, but this new polymer joins a variety of other novel approaches that are helping to bolster recycling efforts.

A biorecycling company is using plastic-eating enzymes to speed up recycling processes, while others are helping transform old plastic waste into useful fuels and even everyday products like soaps, cleaners, and lubricants.

Join our free newsletter for weekly updates on the latest innovations improving our lives and shaping our future, and don’t miss this cool list of easy ways to help yourself while helping the planet.