Researchers at FOM Institute for Atomic and Molecular Physics (AMOLF) in the Netherlands have developed a new type of soft, flexible material that can perform complex calculations, much like computers do matrix-vector multiplications.

Unlike traditional rigid electronics, this elastic metamaterial utilizes “floppy modes”—movements that require almost no energy—to perform computations.

By carefully designing repeating units, researchers can control these deformations to perform different calculations and even reprogram the material after it has been made.

According to the team, this breakthrough could pave the way for smarter soft robots, tiny mechanical sensors, and advanced devices that process information directly within materials, opening new frontiers in soft-matter computing.

Mechanical matrix multiplier

Traditional computing separates the physical world from digital processing: motions, light, or sound are first converted into electrical signals, then sent to processors and memory. This made sense when early computers were large, power-hungry, and costly. However, each conversion step consumes energy, introduces delay, and loses some of the information carried by the original signal.

Researchers are now exploring ways to compute directly in materials, bypassing these conversions. Emerging systems, including optical setups and resistive arrays, focus on matrix-vector multiplication—a key operation in machine learning.

Mechanical systems, especially those involving soft materials, offer low-power alternatives; however, controlling their motion can be challenging. Using floppy modes—motions requiring almost no resistance—can guide predictable deformations, allowing materials to perform computations efficiently.

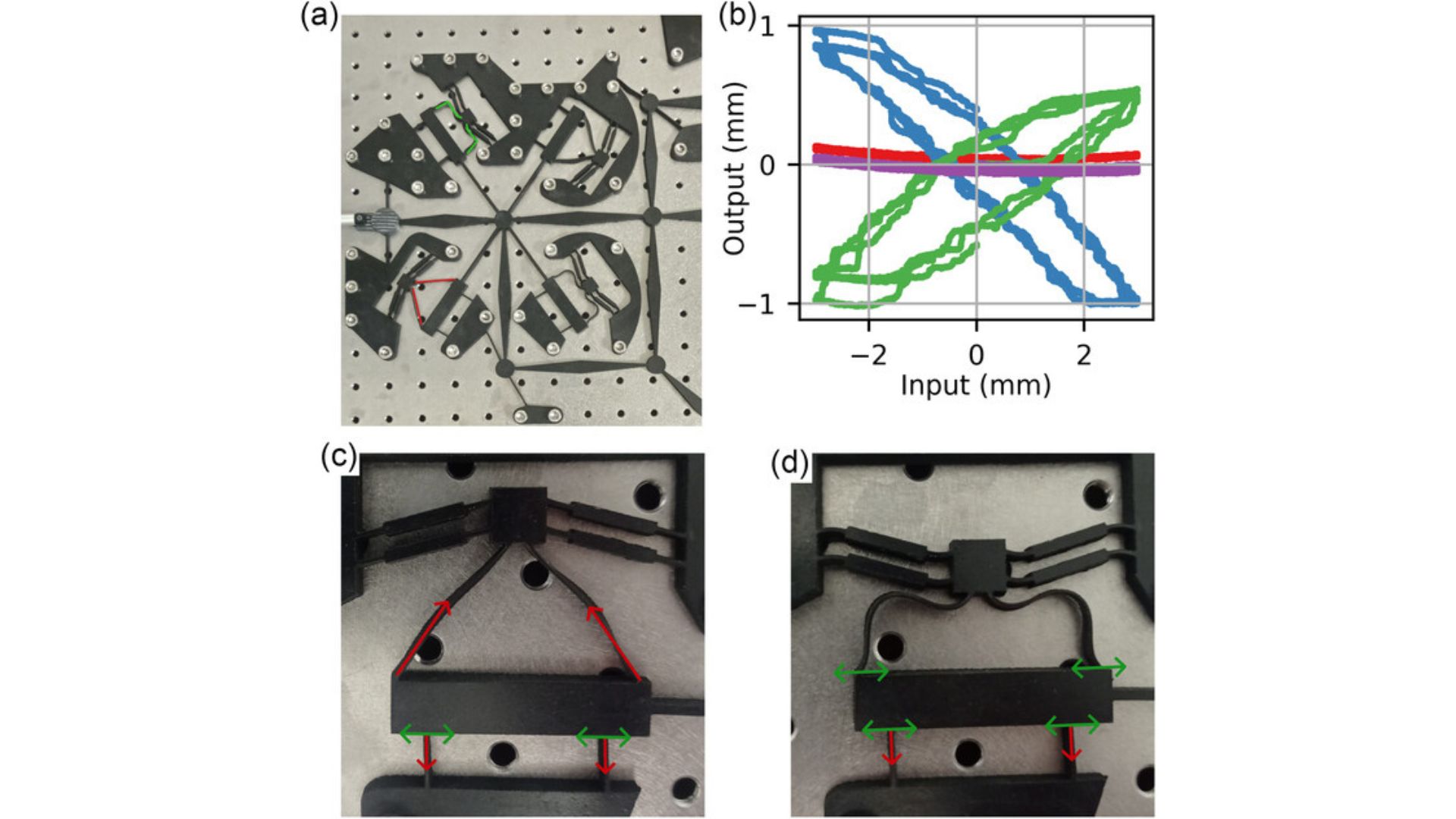

a) Sample shows low-stiffness (green, buckled beams) and high-stiffness (red, straight beams) states. b) Switching matrix coefficients +0.25, 0, −0.33. c,d) Variable stiffness clamps or frees the shaft.

a) Sample shows low-stiffness (green, buckled beams) and high-stiffness (red, straight beams) states. b) Switching matrix coefficients +0.25, 0, −0.33. c,d) Variable stiffness clamps or frees the shaft.

As a remedy, researchers have created a soft mechanical metamaterial—a rubber sheet cut into a repeating pattern—that can perform matrix-vector multiplication using floppy modes, or motions that require almost no energy. Inputs are applied as horizontal or vertical displacements at the sheet’s edges, and outputs appear as movements at other edges, matching the result of a matrix applied to the input vector.

The sheet is made of small tiles, each mapping two inputs to two outputs. Beam angles set tile weights and can be positive or negative. Beams and joints restrict motion to two floppy modes, which combine to produce the desired mapping. Simulations account for real-world bending and stretching using finite element modeling, with automatic differentiation and boundary-focused simplifications ensuring accurate and low-energy computations.

Elastic intelligence material

The study reveals that the performance of the soft mechanical metamaterial is limited by the beam aspect ratio, which is defined as the ratio of the length to the width of each beam. In real materials, large angles that could create bigger matrix weights also stiffen the input path, reducing motion at the output. Calculations suggest that, with current microfabrication capabilities, matrices up to 64 × 64 can be built accurately, which is sufficient for tasks such as speech feature processing.

The team tested a prototype cut from 6 mm rubber. Stepper motors applied small boundary motions, tracked by cameras. Individual tiles followed the expected linear mapping within approximately 20 percent error for small inputs; larger inputs caused saturation, resulting in a sigmoid-like response. Tiles also exhibited hysteresis, which was smaller at slower speeds due to the rubber’s viscoelastic properties, as reported by Nanowerk.

Weights can be adjusted post-fabrication using bistable variable stiffness beams, allowing some matrix entries to switch between positive, negative, or zero. Simulations using automatic differentiation and finite element analysis facilitate efficient design guidance. The team claims the work demonstrates a deformable material performing matrix-vector multiplication directly through motion, without requiring an electrical conversion.

“The results demonstrate that floppy modes can act as key enablers for embodied intelligence, smart micro electro mechanical systems(MEMS) devices, and in-sensor edge computing,” said the researchers in the study abstract.

The details of the team’s research were published in the journal Advanced Intelligent Systems.