WASHINGTON — Boeing announced it has begun 3D printing the structural panels that form the backbone of satellite solar arrays, a step the aerospace giant says will cut production times in half and help it keep pace with demand for faster spacecraft deployment.

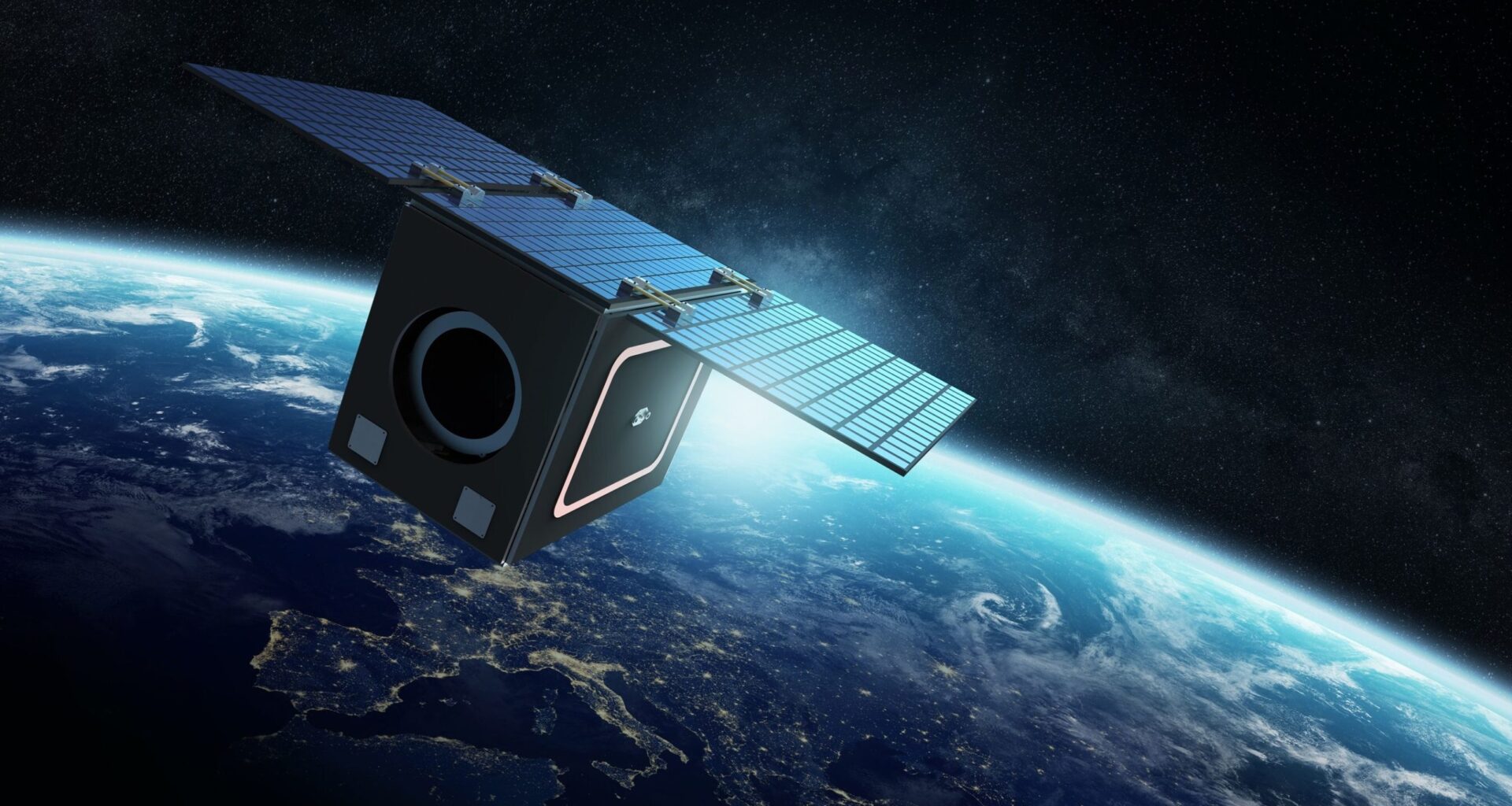

The first 3D-printed arrays will carry Spectrolab solar cells aboard small satellites built by Millennium Space Systems, both subsidiaries of Boeing’s Space Mission Systems division.

Solar array substrates hold solar cells in place and ensure they remain rigid and aligned to capture sunlight in orbit. They are typically built from composite panels in a process that can take weeks, with each array wing requiring extensive manual work.

Boeing said in a news release Sept. 10 that the new additive manufacturing process reduces that timeline by about six months from print to final assembly, representing a production improvement of up to 50%.

By printing structural elements and built-in features directly into the substrate, Boeing says it can assemble the arrays in parallel with cell production. Robot-assisted assembly and automated inspection at Spectrolab are expected to further improve speed and consistency by reducing labor-intensive handoffs.

The approach is designed to scale from small satellites to Boeing’s larger spacecraft platforms, including its 702-class line, with market availability targeted for 2026.

“By pairing qualified materials with a common digital thread and high-rate production, we can lighten structures, craft novel designs, and repeat success across programs,” said Melissa Orme, vice president of materials and structures at Boeing Technology Innovation.

Additive manufacturing has become a growing part of Boeing’s space and defense strategy as it seeks to trim lead times and boost production rates. The company says it has already installed more than 150,000 3D-printed parts across its portfolio, including over 1,000 radio-frequency components on each Wideband Global Satcom military satellite now in production, as well as entire structures for multiple small-satellite product lines.

While 3D printing has long been used for brackets, ducts, and smaller spacecraft components, solar array substrates pose tougher challenges because they must combine ultra-low weight with rigidity and thermal stability while surviving the stresses of launch and orbit.

Related