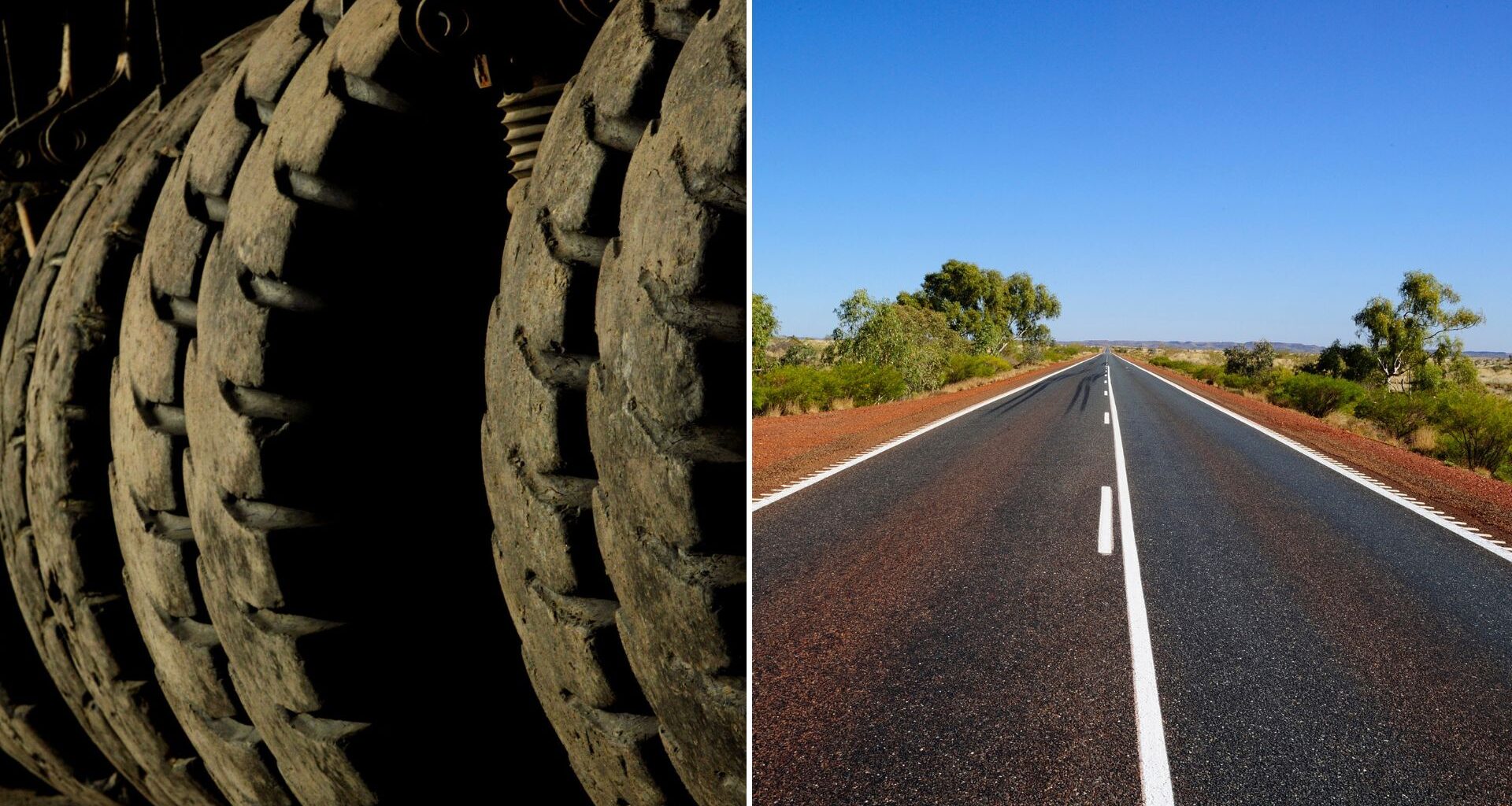

In Australia’s Northern Territory, millions of discarded tires are piling up, with nearly half ending up in landfills and the rest sent interstate for recycling. Now, a team at Charles Darwin University (CDU) is turning that waste into stronger, more sustainable roads.

Their research is testing asphalt and bitumen modified with shredded tires from trucks and passenger vehicles, combined with recycled plastics, to meet the Territory’s unique climate challenges.

The study explores how these materials perform under extreme heat, UV exposure, and other environmental stresses typical of the Northern Territory.

Adapting roads to extreme heat

CDU Ph.D. candidate Ramin Shahbazi, the lead author of the study, explained that roads built for cooler climates often fail under the Territory’s harsh conditions.

“The hot weather up here means the long-term effects of aging roads cause different chemical reactions within the pavement, which makes the road harder or more brittle and leads to damaged roads,” he said.

By incorporating recycled rubber and plastics, Shahbazi said researchers aim to match or even surpass the performance of traditional pavement materials. These materials could also reduce construction costs, avoiding the need for expensive polymers just to withstand local traffic and weather conditions.

“Paying for an expensive polymer just to meet the traffic and weather conditions of Territory roads is like adding an environmental cost to the infrastructure’s overall price tag,” he pointed out.

Testing recycled materials for durability

The project evaluates crumb rubber-modified binder (CRMB) and recycled plastic-modified binder (RPMB) for long-term durability. CRMB shows strong resistance to oxidative, thermal, and UV aging, suggesting it could make asphalt more durable in extreme environments.

In contrast, RPMB’s performance varies depending on polymer type, dosage, and environmental conditions, indicating more research is needed to ensure reliable results.

Moisture-induced damage is also a focus. CRMB can improve aggregate adhesion due to chemical interactions, although undissolved rubber particles might hinder performance.

Asphalt with recycled plastics shows acceptable moisture resistance, but scientists are still studying how plastic properties—like melting point and chemical structure—affect the overall mixture.

Building a circular economy

Shahbazi hopes the research will standardize the use of recycled materials in infrastructure and encourage investment in recycling facilities in the Northern Territory.

“Investing in the specific recycling facilities for these materials will then contribute to the circular economy in the Territory,” he stated in the press release.

Tire Stewardship Australia’s 2023–24 annual report shows that 500,000 metric tons of tires reach the end of their life across the country each year. By repurposing waste into roads, the project could reduce environmental impact while creating cost-effective and climate-resilient infrastructure.

The initiative is a collaboration between CDU and the Northern Territory Government’s Department of Logistics and Infrastructure, aiming to make sustainable, durable roads a reality across one of Australia’s most challenging regions.

The study was published in the Journal of Traffic and Transportation Engineering.