In the fields of civil engineering, aerospace, biomedical engineering, and more, shape memory alloys (SMAs) have garnered widespread attention owing to their distinctive properties. Among them, nickel-titanium (NiTi) alloy stands out as the most commonly used SMA type, thanks to its high strength, superelasticity, corrosion resistance, excellent fatigue life, and remarkable damping capacity. In practical applications like passive vibration control, SMAs are often subjected to cyclic loading. Hence, a thorough investigation into the mechanical behavior of NiTi SMAs under cyclic loading is of great significance for their reliable application in engineering structures.

Against this backdrop, a research team from the Department of Civil and Environmental Engineering at the University of Windsor in Canada has conducted a study titled “Mechanical behavior of NiTi shape memory alloy under cyclic loading: A state-of-the-art review”.

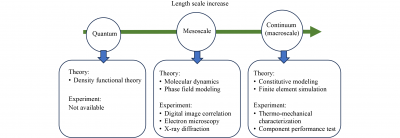

This review primarily focuses on the macroscopic mechanical characteristics of NiTi SMAs under strain-controlled cyclic loading. It first provides a comprehensive overview of the phase transformation mechanism of SMAs, which gives rise to the shape memory effect (SME) and superelasticity (SE). The phase transformation between martensite and austenite phases, triggered by temperature or stress changes, is elaborated, along with the influence of chemical composition and metallurgical processes on transformation temperatures. Additionally, the general mechanical properties of NiTi SMA are compared with those of Fe-Mn-Si SMA, Cu-Al-Ni SMA, and stainless steel.

The review then delves into the mechanical behavior of NiTi SMA under cyclic loading, including the cyclic stress-strain relationship, thermal response, and the effects of various cyclic testing conditions. It analyzes the typical pseudoelastic stress-strain curve features of NiTi SMA under cyclic loading, such as stress overshoot, undershoot, and stress drops. The thermal response during cyclic loading, characterized by temperature changes due to exothermic forward phase transformation and endothermic reverse phase transformation, is also discussed. Moreover, the impacts of key cyclic testing parameters—including the number of cycles, strain amplitude, strain rate, temperature, pre-strain, specimen size, and loading mode—on mechanical responses like equivalent viscous damping, dissipated energy, stress plateaus, and residual strain are systematically summarized.

Furthermore, the fatigue behavior of NiTi SMA, encompassing structural fatigue (leading to material failure due to microstructural damage accumulation) and functional fatigue (resulting in the degradation of mechanical properties like energy dissipation capacity and superelasticity), is reviewed. The concept of “training” to reduce functional fatigue and stabilize material properties is introduced, along with the effects of training conditions on the mechanical behavior of NiTi SMA.

Finally, the review points out existing research gaps and future research directions. These include the need to study the combined effects of material composition and cyclic loading parameters, gain a deeper understanding of the heat balance and temperature evolution mechanism during cyclic loading, conduct more research on large-scale SMA specimens, develop scalable and cost-effective manufacturing techniques, and explore the mechanical behavior of NiTi SMA under stress-controlled cyclic loading corresponding to seismic frequencies, as well as establish design guidelines for SMA-based structural members or devices.

The paper “Mechanical behavior of NiTi shape memory alloy under cyclic loading: A state-of-the-art review” is authored by Danial DAVARNIA, Shaohong CHENG, and Niel VAN ENGELEN. The full text of the paper can be accessed at: https://doi.org/10.1007/s11709-025-1195-2.