Charles Wade, a fourth-year PhD student in CU Boulder’s Department of Computer Science, has developed OpenVCAD, a software package that uses functions and code to define both the shape of a 3D object and how different materials are distributed within it.

“There’s certainly a history of multi-material design study and practice that existed well before OpenVCAD,” said MacCurdy, who is also affiliated with the departments of Computer Science and Electrical, Computer and Energy Engineering. “But we believe the overhead of writing specific code for each project prevents engineers from doing as much design as they could. With OpenVCAD, we’re doing that work once—and doing it really well—so people have built-in infrastructure to represent these spatially varying multimaterial designs.”

Created in the Matter Assembly Computation Lab, led by Assistant Professor Robert MacCurdy of the Paul M. Rady Department of Mechanical Engineering, the tool is the focus of a paper in Additive Manufacturing that explores how it can streamline multi-material 3D printing design.

Addressing the limits of traditional CAD tools

Traditional computer-aided design (CAD) systems typically define objects by their boundary surfaces, assuming that everything inside those boundaries is made from a single material. This makes it difficult to create smoothly blended structures—like a shoe sole that transitions from firm to soft.

OpenVCAD acts as a flexible programming toolkit that lets users define complex material functions and assign them to specific regions in a 3D print. “This is the first multi-material, code-based design tool that is widely available,” Wade said. “It allows for good complexity when printing objects, it’s accessible and it’s intuitive to write and design.”

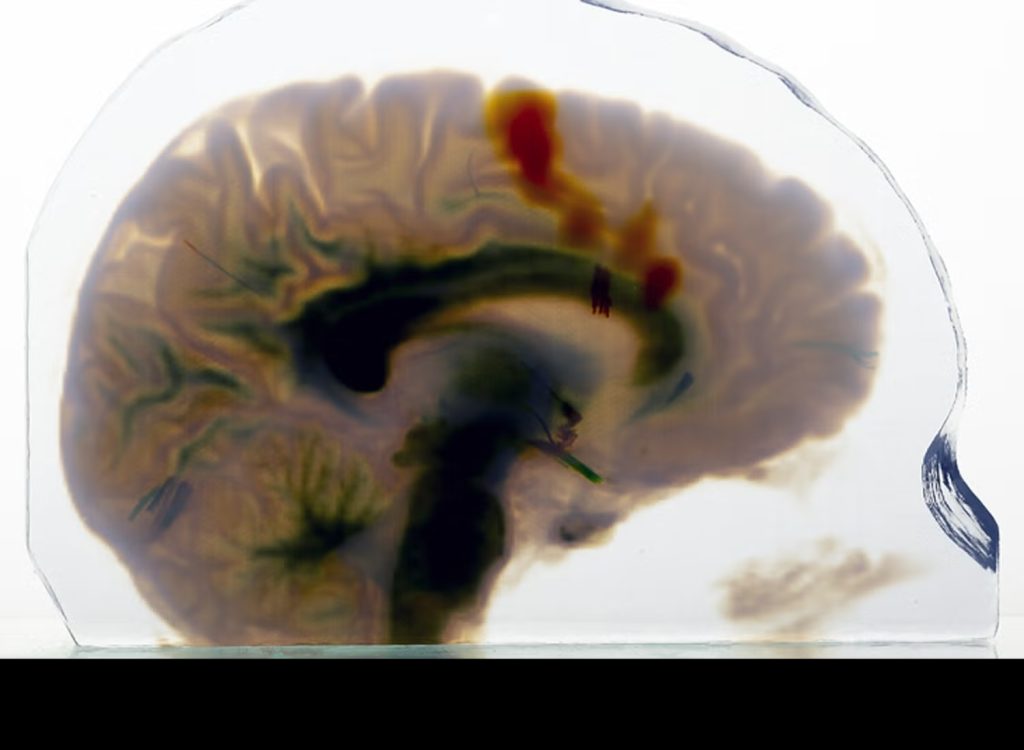

The paper also showcases OpenVCAD’s compatibility with various 3D printer types, including those capable of printing with up to five materials simultaneously. The researchers highlight its broad potential—from medical modeling and soft robotics to engineering simulation and structural design. “We’re able to rely on OpenVCAD’s core capabilities to represent multi-material objects in a bunch of different domains,” said MacCurdy. “But there is a lot more coming that we’re excited about, and we’re hoping this approach to multi-material design takes off.”

As an open-source platform, OpenVCAD is freely available to engineers and researchers worldwide. It includes a Python implementation, allowing users to import the repository and start designing with just one line of code. “We want this to be widely available to people,” Wade said. “We have a growing base of external researchers from other institutions who are using this tool and we hope to enable that community to do their best work.”

From Code to CAD—and Beyond

While OpenVCAD focuses on programmable, function-based design, its development reflects a broader movement toward more accessible and intelligent 3D modeling workflows. Earlier this year, AI software startup Backflip made headlines after raising $30 million in funding. Founded by CEO Greg Mark and CTO David Benhaim, the new generative AI tool can convert images and text prompts into 3D printable parts.

Backed by venture capital firms NEA and Andreessen Horowitz (a16z), the new platform reportedly allows designers to create high-resolution models of complex designs in minutes. Once generated, the files can be 3D printed in metal, carbon fiber, or plastic. According to Mark, Backflip represents a “giant leap forward in bringing design and manufacturing back to the US.”

Elsewhere, 3D printing materials specialist polySpectra offers neThing.xyz. This AI-powered generative design tool allows users to create 3D printable CAD files using straightforward prompts. The tool seeks to make 3D CAD creation more accessible, lowering the barrier of entry to additive manufacturing in the process.

Want to help shape the future of AM? Join the Expert Committee for our 2025 3DPI Awards, launching later this summer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our YouTube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

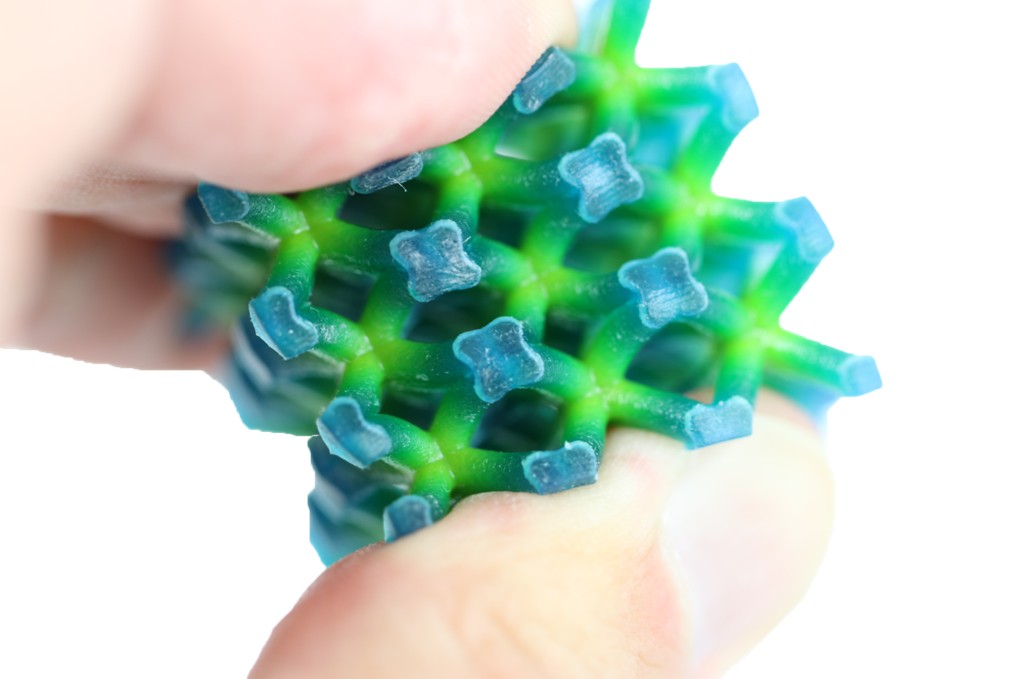

Featured image shows A multi-material lattice structure with a gradient design used for its impact-absorbing capabilities. Photo via CU Boulder.