Flying at high altitudes or traveling in space exposes the human body to extreme changes in pressure, temperature, and oxygen levels—environments that traditional cell cultures fail to mimic. Scientists at Texas A&M University have developed a 3D bioprinting method to study these effects.

The initiative, led by Dr. Zhijian “ZJ” Pei from the College of Engineering in collaboration with Dr. Hongmin Qin from the College of Arts and Sciences—and funded by the U.S. Air Force Office of Scientific Research—aims to enhance aviation and spaceflight safety while accelerating research into respiratory illnesses.

“By investigating how 3D bioprinted samples embedded with lung cells respond to physical stress, we’re advancing the fundamental principles of the effects of extreme environments on human biological systems,” said Dr. Zhijian “ZJ” Pei, Professor of Industrial & Systems Engineering.

Engineering Realistic Lung Models

The researchers’ method combines precision with innovation. Gel-like bioinks containing living cells are loaded into cartridges and printed layer by layer, creating 3D samples that more accurately reflect how human cells behave under stress compared with traditional 2D cultures. “With our 3D approach, we can closely mimic native tissue and their microenvironments, enabling accurate studies of viability, proliferation and stress responses,” said Dr. Hongmin Qin, Professor of Biology.

Exposure to extreme conditions can take a serious toll on human health. For instance, pilots and astronauts risk fluid buildup in the lungs, heat-induced strokes, tissue damage, or organ failure during rapid changes in pressure or temperature. “Our findings shed light on how lung cells respond to physiological and mechanical stressors, including variations in pressure and temperature,” Qin said. “Potential applications could enhance safety protocols for pilots and astronauts in low-orbit conditions.”

Precision and Optimization in Aerospace

Creating realistic 3D bioprinted tissues requires a delicate balance between precision and cell survival. “Even small adjustments in the bioprinting process can dramatically affect cell viability and proliferation,” Qin explained.

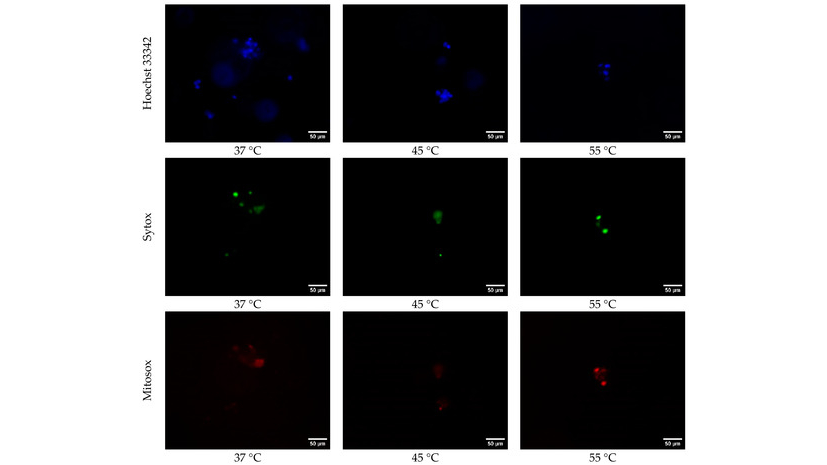

Studies published in Biomimetics and Bioengineering showed that higher extrusion pressures during printing and elevated temperatures up to 55°C increased oxidative stress and cell death, underscoring the importance of precise techniques. To optimize results, the team developed a 4:1 collagen-to-alginate bioink mixture that maintained an impressive 85% cell viability over six days. “Defining the right bioprinting parameters allows us to replicate realistic conditions while preserving cell function,” Pei said.

Beyond aerospace applications, the 3D bioprinting approach provides a more accurate model for studying respiratory diseases such as chronic obstructive pulmonary disease (COPD), which could accelerate drug discovery. “Our long-term goal is to develop engineered lung tissues in a controlled laboratory setting, providing a more realistic model for research than traditional 2D cell cultures,” Qin said.

3D Printing in Space

In recent years, AM companies, academic teams, and commercial organizations have been testing 3D printing technologies in microgravity environments.

In 2023, Redwire successfully bioprinted a human knee meniscus on the ISS using the BioFabrication Facility. The printed meniscus was later returned to Earth aboard SpaceX’s Crew-6 mission for detailed analysis. After printing, the meniscus was cultured on the ISS for 14 days within Redwire’s Advanced Space Experiment Processor (ADSEP). NASA astronauts Frank Rubio, Warren Hoburg, and Stephen Bowen collaborated with UAE astronaut Sultan Al Neyadi to carry out the experiment. This milestone is expected to advance treatments for meniscal injuries in space, a frequent issue for U.S. service members.

Elsewhere, five Belgian companies and research institutions—Space Application Services, SCK CEN, QbD Group, BIO INX and Antleron— joined forces to 3D print an artificial heart and circulatory system, planned for launch to the ISS in 2025. Part of the AstroCardia project, the team aims to study how the heart ages in orbit, where organ ageing occurs up to 20 times faster due to zero-gravity conditions.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

Featured image shows Heat takes a toll: fluorescence images reveal that as the 3D bioprinted samples are exposed to higher temperatures, their stress levels rise and their survival is reduced. Image via Texas A&M.