A new class of soft, programmable composites that can twist, stiffen, and move differently depending on direction may soon redefine how robots sense and act in the world.

A research team at The Hong Kong University of Science and Technology (HKUST) has engineered soft materials with highly tunable, asymmetric mechanical responses, an ability crucial for next-generation mechano-intelligent systems.

The breakthrough integrates “shear-jamming transitions” into compliant polymeric solids, allowing the materials to stiffen dramatically under shear while remaining flexible otherwise.

This design enables soft structures that behave differently when pushed, pulled, or twisted from different directions.

It’s a shift away from traditional metamaterials, which often rely on rigid frameworks that fracture easily. In contrast, these shear-jammed soft composites deliver programmable, defect-tolerant performance without the fragility of conventional designs.

Directional intelligence emerges

In fields like soft robotics, synthetic tissues, and flexible electronics, materials that respond differently depending on the direction of force are key to achieving intelligent behavior. But so far, engineers have mostly relied on complex structures that break easily or fail under stress.

The HKUST team’s approach offers a simpler, more robust path. Their materials can be tuned across multiple scales by controlling how and when the internal particles transition into a shear-jammed state.

This allows directional behaviors, shape-memory asymmetry, and strain-dependent stiffness all within the same soft solid.

“These soft composites are highly programmable and remarkably fracture-resistant,” the researchers noted. They added that the mechanical properties “can be tailored across multiple scales through the shear-jamming phase transition.”

The team also demonstrated how these materials can be combined with spatially modulated magnetic profiles to create “active soft solids” capable of directional motion.

Soft robots advance

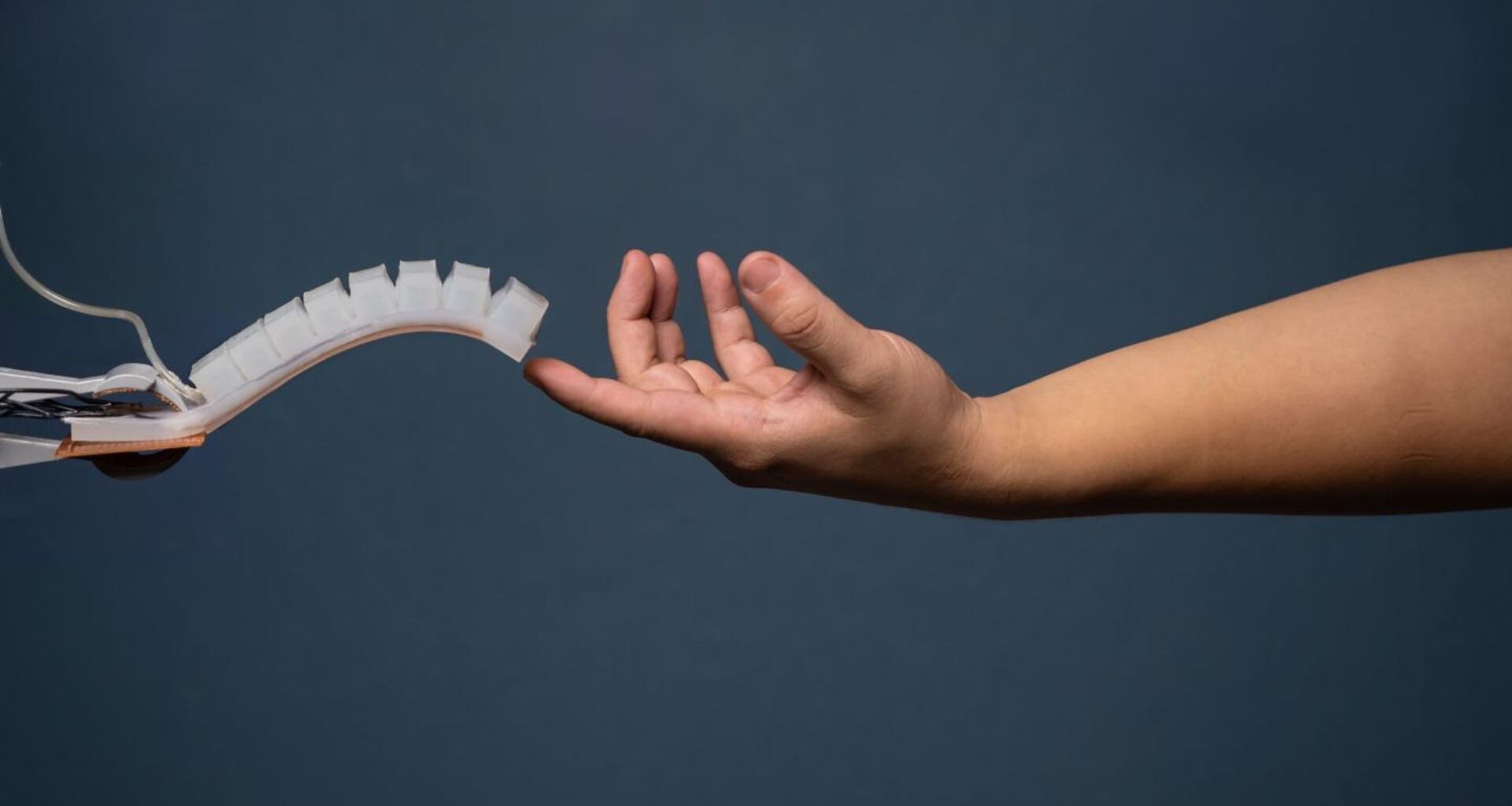

These magnetically guided structures behave like bio-inspired robots, capable of navigating confined environments where conventional robots would stall.

They also function as selective flow-control valves in microfluidic systems, opening cracks for the development of soft pumps, biomedical devices, and adaptive medical tools.

The researchers emphasize that the work bridges granular physics and polymer science, bringing two fields together to craft a new generation of non-reciprocal soft materials.

This convergence enables soft structures that can sense, adapt, and respond with mechanical intelligence rather than relying on electronics alone.

From an engineering standpoint, the results suggest a new design platform for creating directionally sensitive, energy-efficient materials that can interact intelligently with their surroundings.

Such materials could form the backbone of future soft machines and shape-changing devices.

The interdisciplinary project brought together researchers from HKUST’s Departments of Physics (PHYS) and Mechanical and Aerospace Engineering (MAE). XU Chang, a PhD student in PHYS, is the paper’s first author.

The study was supported by the Hong Kong Research Grants Council and the HKUST Marine Robotics and Blue Economy Technology Grant. The findings were published in Nature Materials.