Researchers in the UK have designed a lead-free material with promising piezoelectric properties (J. Am. Chem. Soc. 2025, DOI: 10.1021/jacs.5c15484). Piezoelectrics turn pressure into sparks of electricity, like the flint in a lighter, but usually rely on hard-to-manufacture and toxic ceramic components. The new material, based on bismuth iodide, proved a record piezoelectric performance and expands the options for low-cost, sustainable solutions for sensors, wearables, and printed electronics.

Perovskites and perovskite-related materials, popular for their applications in solar cells, have been very well known for presenting piezoelectric properties, explains first author Esther Hung, from the University of Oxford. Although many studies have demonstrated that perovskites and related materials can perform comparably to conventional ceramic piezoelectrics, most count on toxic metals like lead. In this case, however, researchers “carefully chose organic and inorganic components to design a lead-free piezoelectric—based on bismuth iodide—which has a record piezoelectric performance,” Hung says.

In this case, the components create an artificial asymmetry in the material’s structure, which induces a distortion and a separation of electrostatic charges. This separation, also commonly called polarization, creates the conditions necessary for the material to respond to pressure and produce the piezoelectric effect. The new material exhibits the highest piezoelectric coefficient ever reported for this type of compound, generating a strong electric response relative to the pressure applied. The structure, similar to a perovskite’s, consists of an organic cation and an inorganic iodobismuthate, an anion containing iodine and bismuth.

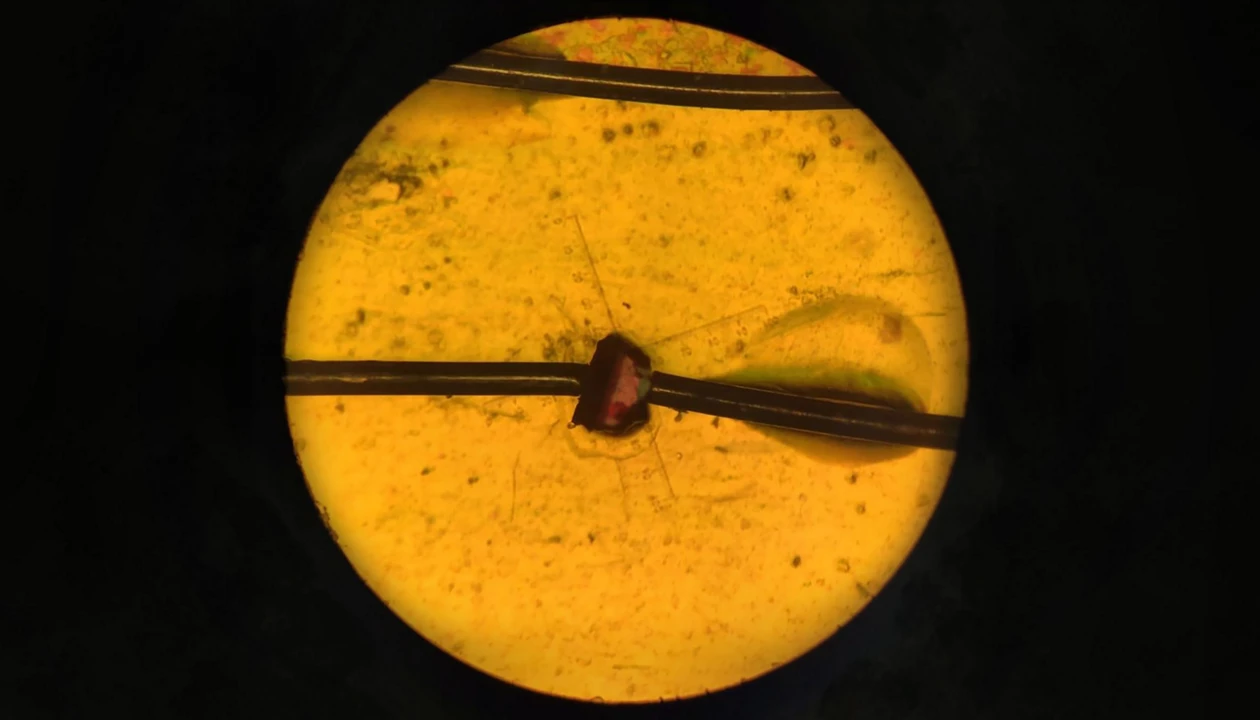

Under pressure, piezoelectric materials generate an electric current. This effect is used in applications from flints in lighters to sensitive sensors in laboratories.

Credit:

Tizeff/Wikimedia, CC BY-SA 3.0

In a computational calculation, an organic cation with added asymmetry displayed a polarization six times stronger than that of a symmetric structure. The effect is even greater in the case of the inorganic anion, which “introduces intermolecular interactions to intentionally induce tilting and distortion and increase asymmetry,” explains Jovana V. Milić, a specialist in smart materials at the University of Turku who was not involved in the new work. Overall, the modifications to the cation and anion bump polarization up to 10 times stronger than with symmetric structures, a result supported by the experimental measurements of piezoelectric properties. “This enhanced polarization is critical for the piezoelectric response,” Milić adds.

Besides the material lacking lead-based components, the synthesis strategy for this new material is also more sustainable. “In stark contrast to ceramic piezoelectric materials, which usually require hundreds of hours of processing and high-temperature, high-pressure processes, [our] material is synthesized as single crystals in under an hour and below 100 °C,” Hung says. And mechanochemical methods make the preparation of bulk batches of this piezoelectric appealing for an easy scale-up. “The synthesis strategies are based on common methods, such as single-crystal growth, thin film [processing], and mechanosynthesis, which means the material [could be] implemented by engineers,” Hung adds.

“This new halobismutate, a lead-free material, shows a record-high piezoelectric response,” explains Luis Lanzetta, an expert in perovskite-related materials at the Institute of Advanced Materials at the University Jaume I, who was not involved in the study. “Such performance is highly promising since it’s comparable to commercial lead-based piezoelectrics, which remain quite toxic and hard to fabricate.” Lanzetta also praises the resourcefulness of this research, since similar halides have rarely been explored as piezoelectrics. “Most studies focus on the optoelectronics properties for uses in solar cells and light-emitting diodes,” he says. “These piezoelectric properties are yet another example of their versatility.”

“The competitive characteristics of this lead-free material . . . open the way to more sustainable piezoelectrics,” Milić explains. The ceramic structures of conventional piezoelectrics are usually incompatible with emerging applications in printed electronics, which require flexibility and low-cost manufacturing. Since the new piezoelectric is more sustainable, is nontoxic, and performs comparably to commercial inorganic piezoelectrics, it is better suited for smart electronics. The processing of piezoelectrics into solutions and thin films facilitates the fabrication of smart devices, using systems already available in semiconductor fabrication plants. Lead-free piezoelectrics could overcome the strict international regulations restricting hazardous chemicals, and could also become “particularly relevant for emerging technologies, such as wearables, sensors, and self-powered flexible electronics,” Milić says.

Chemical & Engineering News

ISSN 0009-2347

Copyright ©

2026 American Chemical Society