Researchers at Nanjing Tech University have created an AI model that predicts metal temperatures in real time during 3D printing, offering a way to improve the consistency and quality of 3D printed parts.

Led by Mingxuan Tian of the School of Mechanical and Power Engineering, the study introduces a physics-informed machine learning system capable of forecasting temperature changes in wire arc additive manufacturing (WAAM).

Published in Communications Engineering, the study demonstrates how combining physical laws with AI can improve the speed, accuracy, and adaptability of temperature prediction in industrial metal 3D printing, supporting more consistent production of high-performance parts.

Controlling temperature in metal 3D printing is essential, as uneven heating or cooling can cause cracks, stress, and distortions that weaken parts. While finite element simulations provide accurate predictions, they take hours to compute. In contrast, faster data-driven models often accumulate errors and struggle to adapt to changing conditions.

Called a physics-informed geometric recurrent neural network, the new system integrates physical principles with deep learning. It learns from both data and heat conduction laws to keep predictions physically realistic, incorporating geometry, material properties, and process parameters to capture the molten metal’s dynamic behavior during printing.

AI-powered temperature prediction

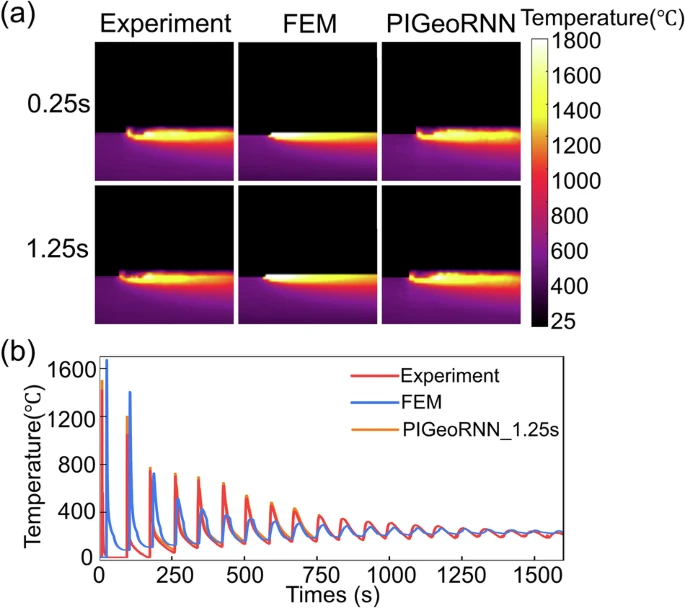

In tests using both simulations and experiments, the model analyzed the most recent 1.25 seconds of temperature data to forecast the next 1.25 seconds of thermal behavior, a critical window for process control. It achieved a maximum prediction error between 4.5% (in simulations) and about 13.9% (in experiments) depending on the data source and generated results within approximately 12 milliseconds of prediction time, fast enough to support real-time feedback.

Compared with conventional finite element simulations that require about an hour to complete, the AI model provides near-instant predictions. Incorporating geometric and physical inputs reduced the maximum error by about 1%, while combining both lowered it by around 4%. When trained using transfer learning, first on simulated data and then refined on experimental data, the system cut training time by 50% without losing accuracy.

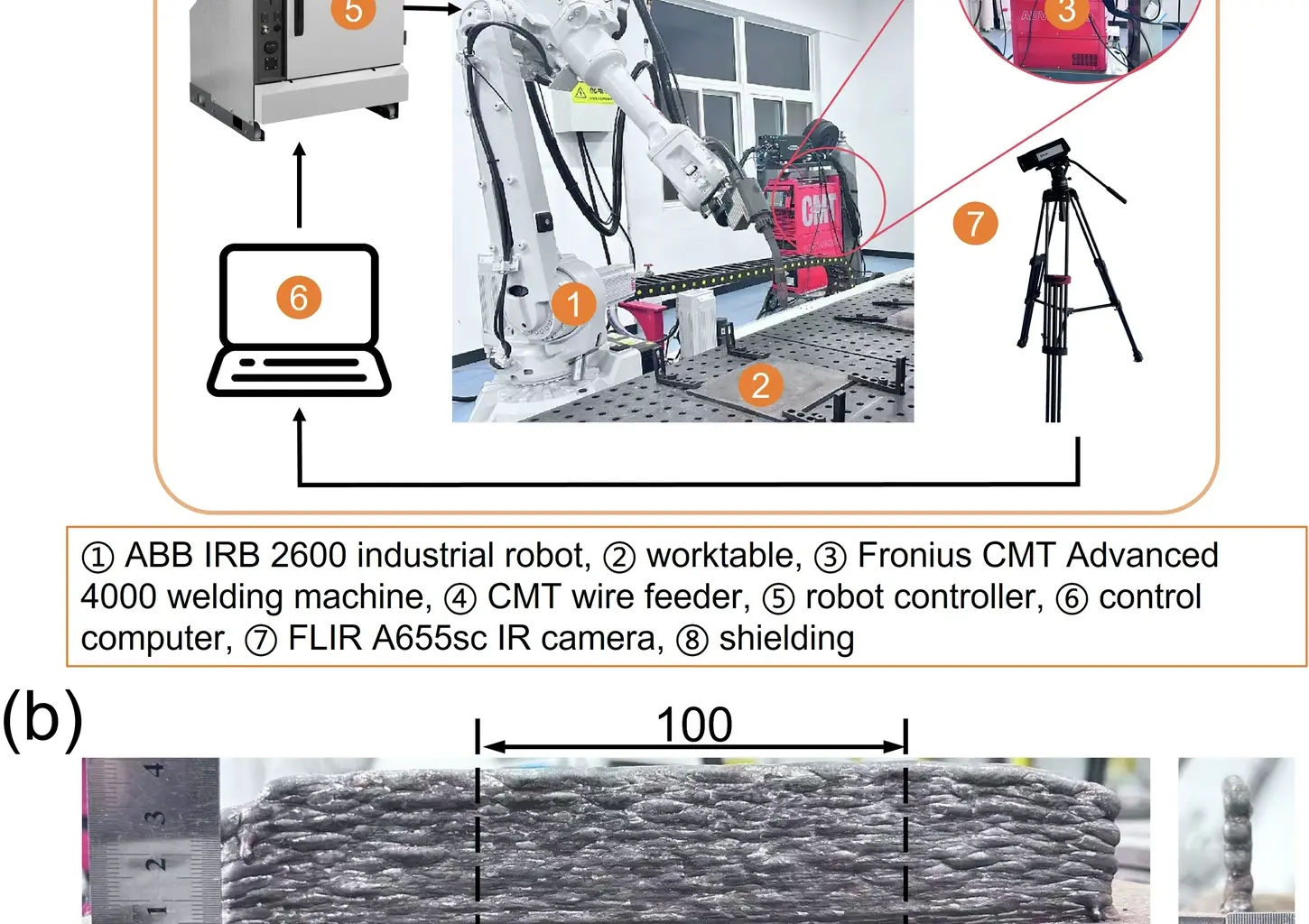

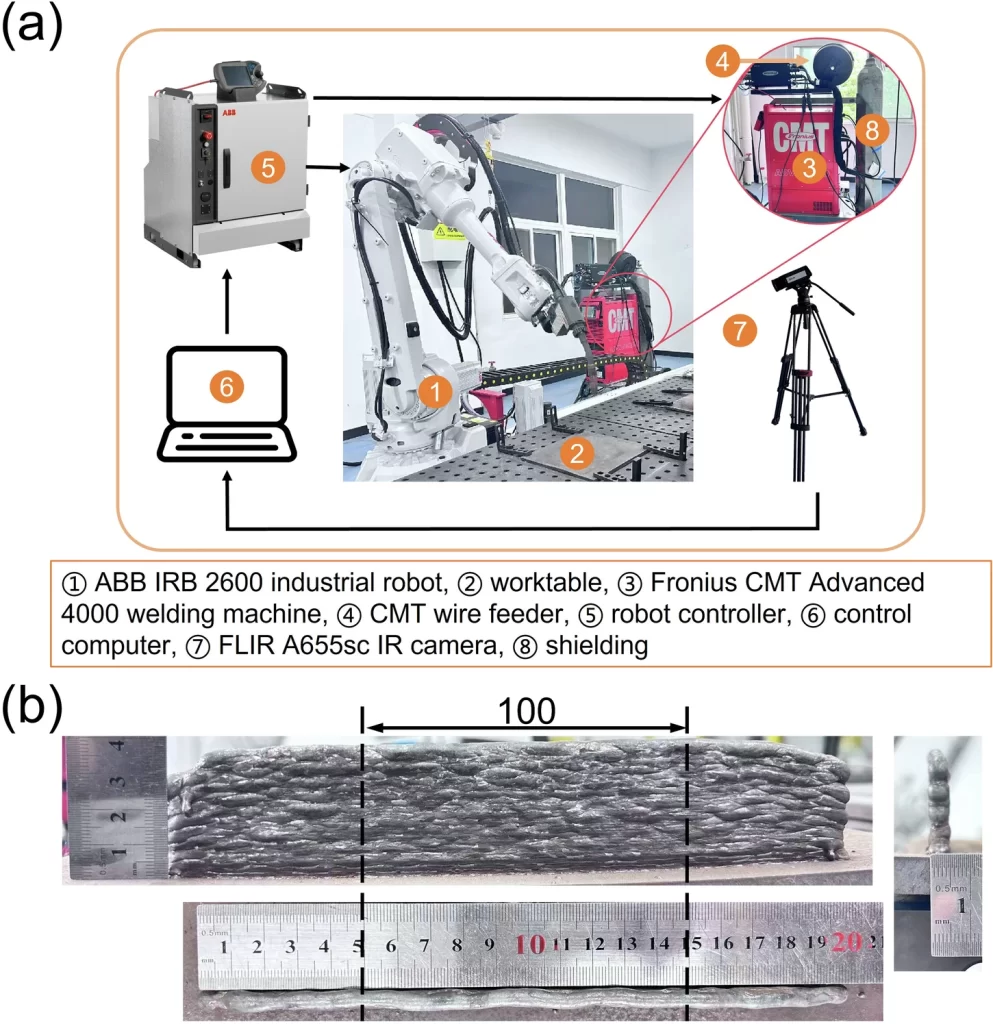

Experiments using a robotic WAAM setup confirmed the model’s practical performance. A thermal camera monitored the process as the system deposited thin-wall steel structures layer by layer. Despite variations caused by surface emissivity and environmental factors, the model accurately tracked temperature evolution and remained stable in forecasts extending up to about 10 seconds (tested up to 11.25 seconds), a key period for managing heat flow and reducing residual stress.

By embedding physical constraints directly into the network, the model limits the buildup of cumulative errors that often occur in long-term predictions. This is achieved through hard-encoding of boundary conditions and a physics-informed loss function, ensuring the results align with real-world thermal behavior. The researchers found that this combination of physical knowledge and data learning allows the system to generalize effectively across different process settings and component geometries.

According to the study, the method could enable feed-forward control in additive manufacturing, allowing machines to adjust process parameters such as heat input or wire feed speed before problems occur. It could also play a role in digital twin systems that replicate manufacturing processes in real time, improving monitoring, process optimization, and quality assurance.

Although the research focused on WAAM, the same approach could be adapted for other techniques such as laser or electron-beam deposition by retraining the model with process-specific data.

The work highlights how integrating physics with machine learning can overcome the limitations of purely computational or data-driven approaches, advancing the ability to predict and control complex thermal processes in metal 3D printing.

Novel models for predicting heat flow

In metal 3D printing, temperature predictions are the hidden key to quality, guiding how metal melts and solidifies into strong, reliable structures. When done right, they prevent costly defects and distortion, turning complex digital designs into flawless physical parts.

For instance, Northwestern University and Case Western Reserve University researchers developed a digital twin framework to optimize laser-directed energy deposition (DED) through machine learning and Bayesian optimization. The system integrated a Bayesian Long Short-Term Memory (LSTM) neural network for real-time prediction of temperature evolution with a Bayesian optimization algorithm for time-series process control.

Trained on Inconel 718 data, the model achieved an R² of 0.75 and quantified uncertainty for adaptive feedback. The optimization method, BOTSPO, improved heat-treatment time by 26%, demonstrating a data-efficient path toward autonomous, self-correcting DED systems capable of real-time predictive control.

In 2021, researchers from the University of Nebraska–Lincoln, Drexel University, Navajo Technical University, and SigmaLabs developed a digital twin approach for detecting flaws in laser powder bed fusion (LPBF) 3D printing. The method combined in-situ meltpool temperature measurements with a physics-based thermal simulation model that updated temperature distribution predictions layer by layer.

Tested on stainless steel impellers printed with intentional defects, the system detected process drifts, lens delamination, and cyber intrusions in real time. By integrating temperature data across micro- and macro-scales, the model enabled precise, interpretable flaw detection while reducing delays, data dependence, and waste in metal AM.

Help choose the 2025 3D Printing Industry Awards winners – sign up for the Expert Committee now!

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on LinkedIn.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows illustration of the experimental system and deposition cases. Image via Communications Engineering / Nanjing Tech University.