Renders of inside the new 28-bed ward at Hawke’s Bay Hospital in 2026.

Southbase North Island manager Marcus Beddis said the programme is an example of how combining repeatable designs with offsite construction can deliver healthcare infrastructure faster and more cost-effectively than ever before.

“By manufacturing components offsite, we can ensure high quality, consistency, and speed, without compromising on design or durability.”

Beddis said “around seven” 8x17m modules, each just over 4m high, will be built at Southbase’s South Auckland factory and then transported to Hawke’s Bay Hospital on trucks.

He said that enables the company to focus on efficiency, quality, precision and cleanliness of the new buildings.

One of the key design considerations for the module buildings is they can be transported safely on roads.

Each module will be wrapped, so they’re still in a fully controlled environments when being moved.

“These hospitals are clinical facilities,” Beddis said.

“Doing this in a controlled factory environment, and where we can bring all our supply chain partners in the dry and in the warmth, we can do some really high-quality stuff.”

Southbase will establish itself at the hospital around March and once the modules have been transported to Hastings, they will be craned into position onto the foundations and connected together to form one 28-bed ward, which will then be connected to the rest of the hospital.

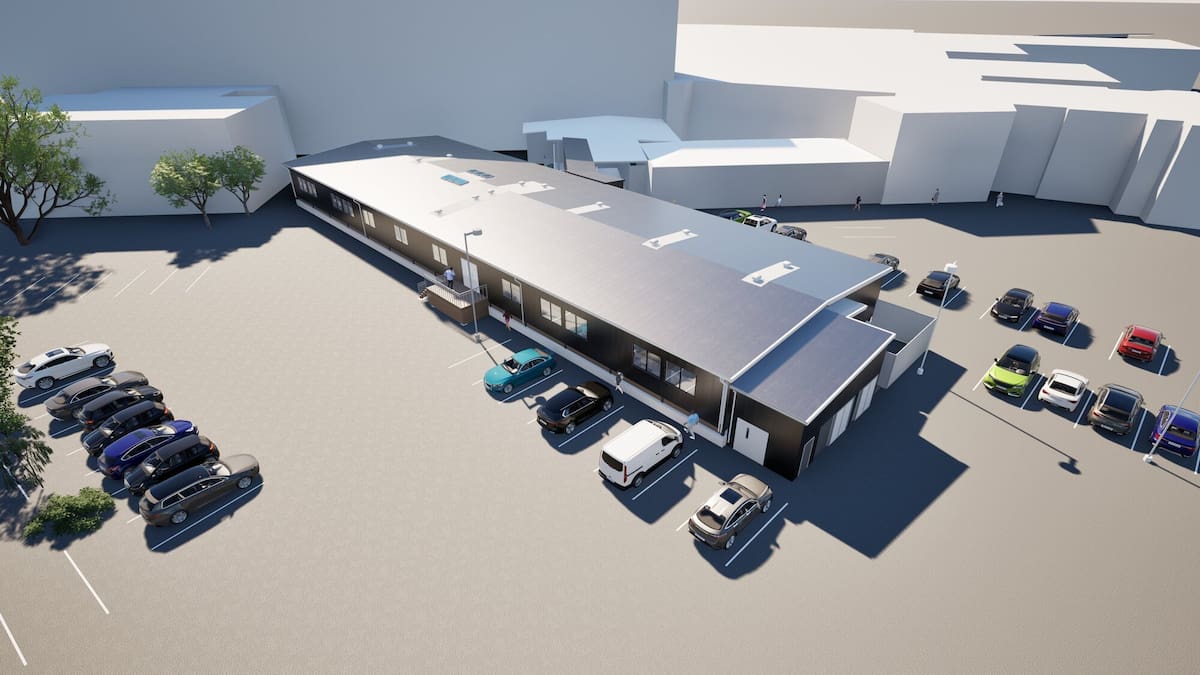

Renders of the new ward made up of seven modules to be installed at Hawke’s Bay Hospital in 2026.

Beddis said the ward has a design life of 50 years and is designed to the Australasian Health Facility Guidelines.

“But in terms of the actual fit out of the wards – that is going to be similar, if not better than a new build hospital in New Zealand.”

Beddis is aware offsite manufacturing typically conjures images of garden sheds and cabins, but pointed to what the Ministry of Education has been able to achieve with its modular classrooms as proof of concept that prefabricated buildings are a valuable option for replacing or updating government buildings.

“They are outstanding, and really that’s what can be achieved in a controlled factory environment.

“It’s a design that’s been refined over time … and when it’s constructed at volume in a controlled environment, we can drive all the efficiencies in cost and quality and time into it because we can perfect it.

“By doing it this way, we can get better and better.”

Tuktuki MP Catherine Wedd said the new ward and its 28 beds will help the hospital admit, treat, and discharge patients more efficiently.

“This practical, cost-effective approach expands hospital capacity rapidly while minimising disruption to existing services.

“The rapid-build ward is an important step to ensure Hawke’s Bay families can access the care they need, when they need it.”

Jack Riddell is a multimedia journalist with Hawke’s Bay Today and has worked in radio and media in the UK, Germany, and New Zealand.