Researchers in the United States have recovered lithium from battery waste using an electrochemically driven recovery process. Lithium is a critical element used in rechargeable batteries and susceptible to supply chain disruption.

The new method has been tested on commonly used types of lithium-containing batteries.

The research reveals a process that leaches metals from batteries into an organic solvent, then uses an electrochemical cell in which a polymer-coated electrode is used to capture lithium.

Copolymer captures lithium selectively directly from organic solvents

“The main challenge is the presence of other metals in lithium recovery streams, particularly in organic leachates, which is a common way to dissolve spent batteries for recycling,” said Xiao Su, chemical and biomolecular engineering professor from University of Illinois Urbana-Champaign.

“To overcome these challenges, we’ve introduced a copolymer that captures lithium selectively directly from organic solvents and that can be electrochemically regenerated,” said Su.

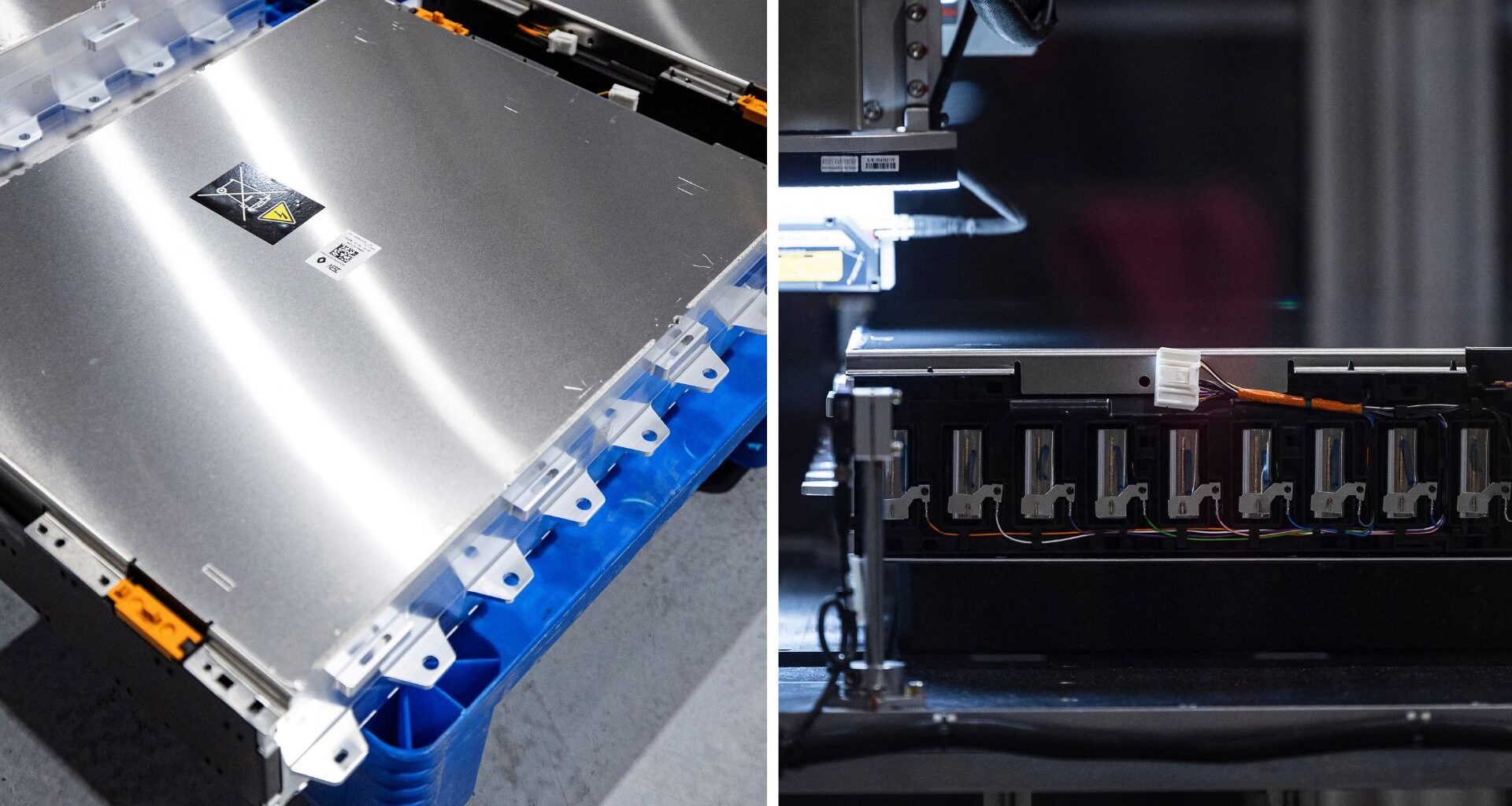

In the lab, Su’s research team dismantles batteries and leaches out metals into an organic solvent, creating a mixture containing lithium and other metals. They then moved the solvent into an electrochemical cell with an electrode coated with a specially designed copolymer that specifically captures lithium ions from the mixture, much like a sponge, according to a press release.

Lithium-filled electrode is then put into a new solution

“The lithium-filled electrode is then put into a new solution, and a voltage is applied. That triggers the polymer to release the captured lithium ions, which are collected, while leaving other metals behind in the original leachate. This electrochemical regeneration allows for repeated cycles of selective, efficient lithium recovery from waste batteries.”

Su’s research in resource recovery typically includes an economic viability analysis, and this study follows with that hallmark.

“We found that, using a three-stage approach, the recovered lithium could be produced at a cost that is economically favorable compared to current lithium market prices,” he said.

Increasing demand for lithium

Researchers also underlined that the increasing demand for lithium, alongside concerns over resource scarcity and supply chain risks, has driven the need for alternative lithium sources, particularly from spent lithium-ion batteries (LIBs).

Published in the journal ACS Energy Letters, the study introduce a redox-active crown ether copolymer designed for highly selective and electrochemically reversible lithium recovery from organic LIB leachates.

A lithium-selective moiety, (12-crown-4)methyl methacrylate (12C4MA), is combined with a redox-active moiety, ferrocenylpropyl methacrylamide (FPMAm), into a redox copolymer electrosorbent to replace acid-based regeneration with electrostatic repulsion, according to researchers.

“The redox response enhances lithium ingress into the polymer, doubling lithium uptake (0.58 molLi/molCrE) and enabling electrochemical regeneration upon the FPMAm oxidation. Our system exhibits exclusive lithium uptake, even in complex leachates containing competing metals (e.g., iron, nickel, and cobalt) and organic degradants,” said researchers.

The team pointed out that the techno-economic analysis highlights high energy efficiency and competitive lithium pricing to the market value (∼$12.7 per kgLi). Overall, our work demonstrates a scalable, electrified adsorbent platform for sustainable and chemical-free critical metal recovery.

Significantly less expensive method

The new method could be significantly less expensive or at least cost-competitive with existing methods of lithium production. While the proof-of-concept results are very promising, there is still room for more work in scaling up the system as well as process modeling to validate their findings further, as per the release.

“These results help highlight the broad applicability of electrochemical separations for metal recycling, not only in water, but also from organic solvents that are commonly used to leach waste batteries. We envision this work helping establish a more circular, sustainable supply chain for lithium, enhancing supply security and potentially reducing the environmental impacts associated with other forms of lithium extraction, such as mining.”