Rocket propulsion technology has evolved from ancient Chinese gunpowder filled bamboo tubes that shot off into opposing armies to the powerful engines of Saturn V and more recently the Space Launch Vehicle and Falcon 9. The journey progressed through centuries of experimentation by pioneers like Konstantin Tsiolkovsky, Robert Goddard, and Hermann Oberth who laid the foundations for modern rocketry. The space race dramatically accelerated development of new technology, producing the liquid fuelled engines that launched Sputnik, sent humans to the Moon, and built the International Space Station.

The Apollo 11 Saturn V rocket launch vehicle lifts-off with astronauts Neil A. Armstrong, Michael Collins and Edwin E. Aldrin, Jr., at 9:32 a.m. EDT July 16, 1969, from Kennedy Space Centre’s Launch Complex Pad 39A (Credit : NASA)

The Apollo 11 Saturn V rocket launch vehicle lifts-off with astronauts Neil A. Armstrong, Michael Collins and Edwin E. Aldrin, Jr., at 9:32 a.m. EDT July 16, 1969, from Kennedy Space Centre’s Launch Complex Pad 39A (Credit : NASA)

Rotating detonation engines (RDEs) represent quite the departure from conventional propulsion systems. Instead of the controlled burning – and I must call out its scientific term since it’s one of my favourite words, deflagration – used in traditional engines, RDEs harness the power of supersonic combustion that releases energy far more efficiently. The RDE generates power through sustaining a circulating detonation wave in an annular chamber at thousands of meters per second, creating what researchers describe as a controlled explosion that continuously races around inside a circular chamber.

Compared to the more conventional combustion based rocket engines, RDEs are, at least theoretically up to 25% more efficient. With the increase in efficiency comes reduced fuel costs and weight. When it comes to space travel, this could mean delivering satellites to precise orbits with significantly reduced fuel consumption, emissions and costs. There is a catch though, and it’s quite a big one! The extreme conditions inside an RDE create what might be one of the most challenging engineering problem in modern rocketry. The extreme thermal changes and mechanical loadings that repeated detonations generate pose a challenge for any existing materials to be able to sustain. The detonation waves traveling at several kilometres per second, wave frequencies in the kilohertz range, and the constant battering of pressure waves that can reach extreme temperatures and pressures. Traditional materials simply can’t handle this for extended periods.

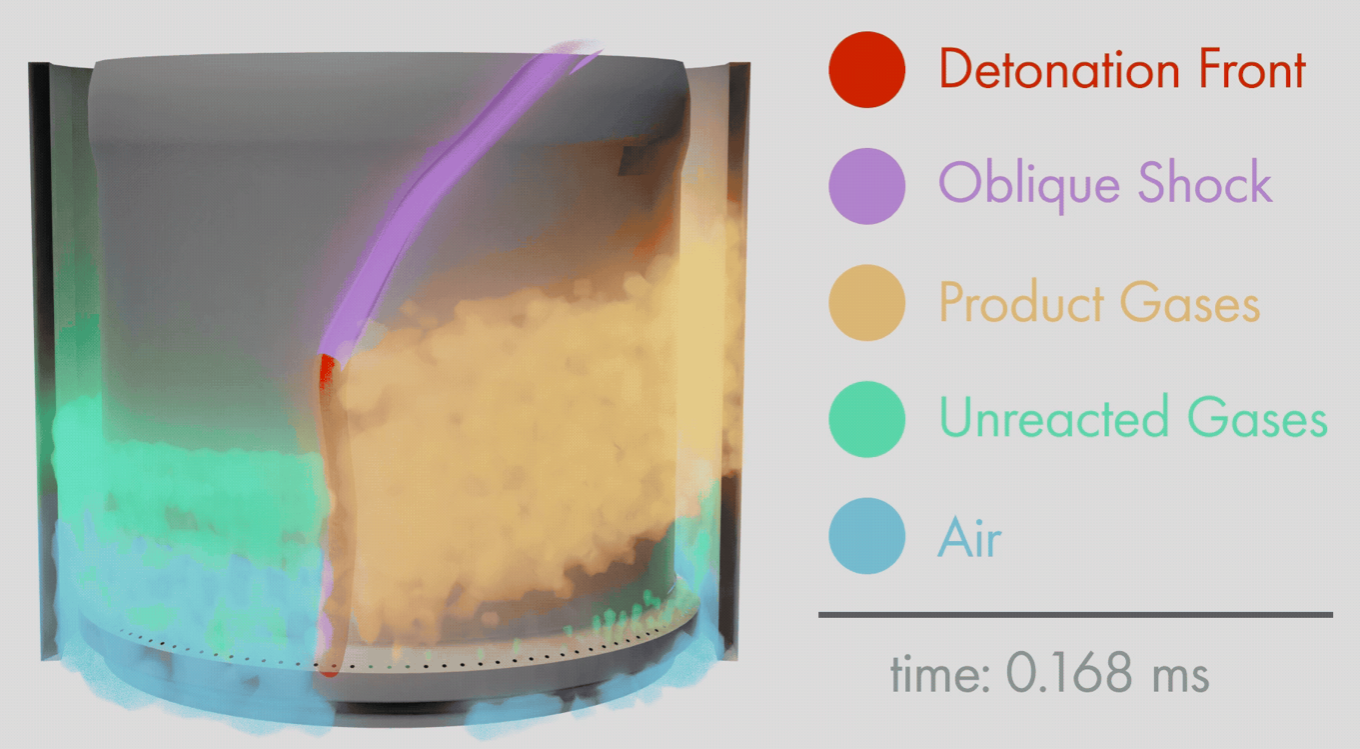

Conceptual animation of RDE flow field (Credit : Oak Ridge National Laboratory)

Conceptual animation of RDE flow field (Credit : Oak Ridge National Laboratory)

Thankfully this isn’t the end of the story. Thanks to investment of a $2 million grant, a team of researchers led by Natasha Vermaak from Lehigh University have started to explore and develop new materials resistant to the high frequency thermomechanical loads. The team is a collaboration of experts from Lehigh University, Carnegie Mellon University, and the University of California Irvine, along with partners from the Air Force Research Laboratory.

This isn’t the first time research into RDEs has been undertaken. Since 2010, Aerojet Rocketdyne has conducted over 520 tests of multiple configurations and possible materials, and in May 2020, a team affiliated with the US Air Force developed a working model rotating detonation engine capable of producing 200 pounds of thrust. In 2021, Japan Aerospace Exploration Agency (JAXA) succeeded in testing the RDE in space for the first time.

The materials challenge facing Vermaak’s team demonstrates how materials science often determines what’s possible in advanced technology. Throughout history, technological breakthroughs have frequently been limited not by our understanding of physics, but by our ability to create materials to perform certain functions. It’s a rapidly evolving field thought that is driven by advances in computer modelling and nanotechnology that allows engineers to design materials to their exact requirements. Yet rotating detonation engines present a particularly challenging environment that pushes beyond current capabilities. Engineers must first solve the challenge of building materials tough enough to survive thousands of controlled explosions per second before the RDE becomes an integral part of space exploration.

Source : Designing materials for next-generation propulsion systems