A team of researchers led by Rice University’s James Tour and Shichen Xu has unveiled a lightning-fast method to recover rare earth elements (REEs) from discarded magnets.

The technique promises substantial environmental and economic benefits compared with traditional recycling methods.

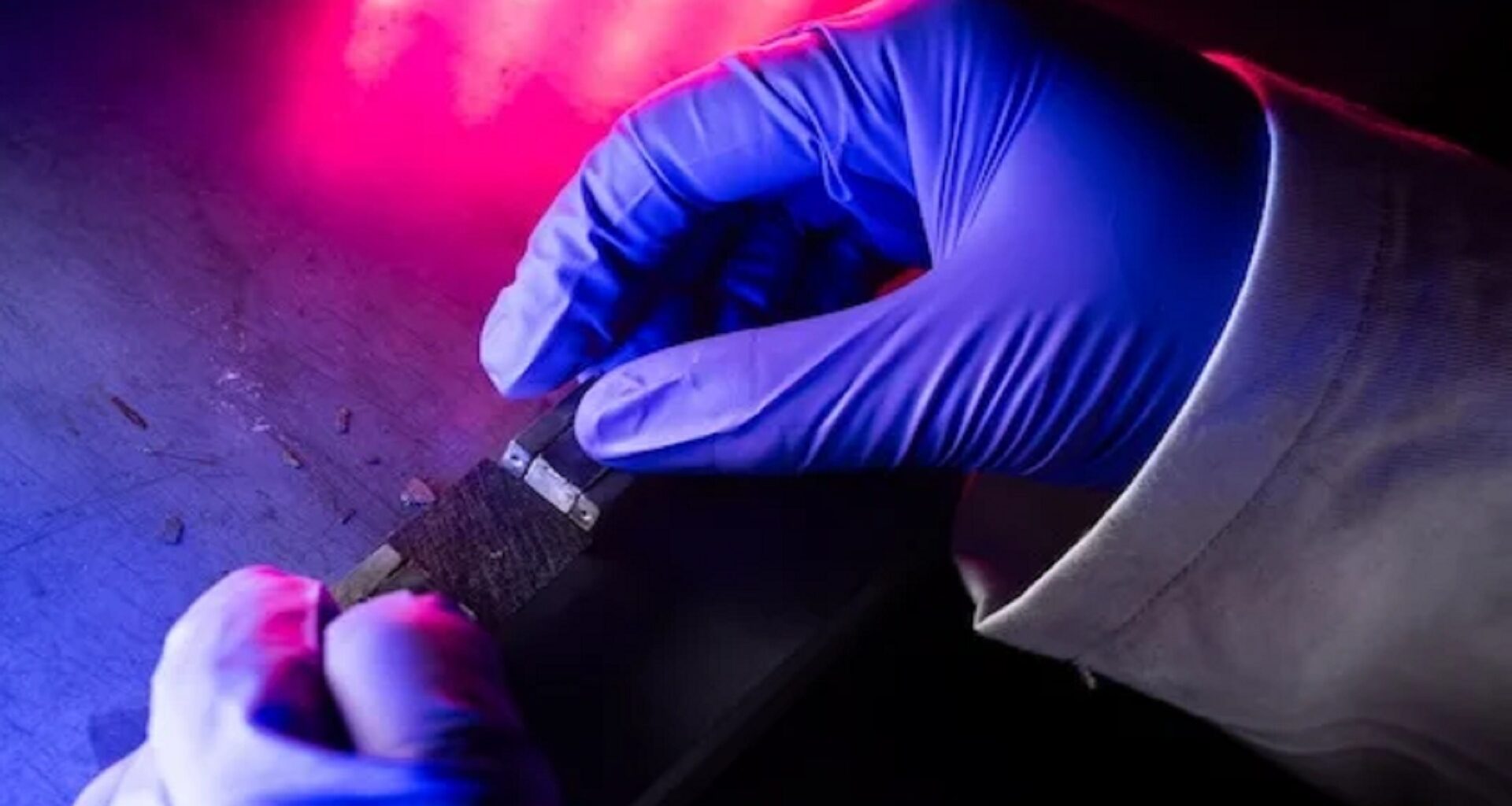

Conventional rare earth recycling is energy-intensive and generates toxic waste. The new approach uses flash Joule heating (FJH), which rapidly raises material temperatures to thousands of degrees in milliseconds, combined with chlorine gas to extract REEs in seconds.

The method does not require water or acids, a key improvement for greener processing.

“We’ve demonstrated that we can recover rare earth elements from electronic waste in seconds with minimal environmental footprint,” said Tour, the T.T. and W.F. Chao Professor of Chemistry, professor of materials science and nanoengineering, and study corresponding author.

“It’s the kind of leap forward we need to secure a resilient and circular supply chain.”

The approach aligns with U.S. efforts to strengthen domestic mineral supplies and reduce dependence on imports of critical materials.

Thermodynamics drives selective recovery

The researchers hypothesized that FJH combined with chlorine gas could exploit differences in Gibbs free energy and boiling points to selectively remove non-REE elements from magnet waste.

In practice, iron, cobalt, and other non-REE elements chlorinate and vaporize first, leaving behind the REE oxides. The team tested this on neodymium iron boron and samarium cobalt magnet waste.

By precisely controlling temperatures within seconds, non-REEs converted into volatile chlorides, separating cleanly from the solid REEs.

“The thermodynamic advantage made the process both efficient and clean,” said Xu, the first author of the study and a postdoctoral associate at Rice.

“This method not only works in tiny fractions of the time compared to traditional routes, but it also avoids any use of water or acid, something that wasn’t thought possible until now.”

Laboratory experiments were complemented by life cycle assessments (LCA) and techno-economic analyses (TEA).

The team achieved over 90 percent purity and yield for REE recovery in a single step. LCA and TEA results showed an 87 percent reduction in energy use, an 84 percent decrease in greenhouse gas emissions, and a 54 percent cut in operating costs compared to hydrometallurgy.

Toward circular rare earth economy

This ultrafast process makes it feasible to build small or large recycling units near electronic waste collection points. Localized systems can process used magnets quickly and cleanly, reducing shipping costs and environmental impact.

“The results show that this is more than an academic exercise — it’s a viable industrial pathway,” Tour said.

Rice University has licensed the intellectual property to Flash Metals USA, a Texas startup that plans to enter production by Q1 2026.

Co-authors include Rice researchers Justin Sharp, Bing Deng, Qiming Liu, Lucas Eddy, Weiqiang Chen, Jaeho Shin, Shihui Chen, Haoxin Ye, Khalil JeBailey, Bowen Li, Tengda Si, and Kai Gong. Funding came from the Defense Advanced Research Projects Agency, the Air Force Office of Scientific Research, and the U.S. Army Corps of Engineers.

This development represents a major step toward a scalable, circular, and environmentally responsible rare earth economy, potentially transforming how critical materials are recovered worldwide.