Researchers in Switzerland have taken an important step toward circular mobility by developing a robotic system that extends the sustainable second life of electric vehicle (EV) batteries.

Completed under the CircuBAT research project, the innovative solution closes the loop between production, use, and recycling of automotive lithium-ion (Li-ion) batteries.

Led by the Bern University of Applied Sciences (BFH), the project brought together seven Swiss research institutions and 24 companies to investigate novel ways of optimizing every stage of a battery’s life.

Over the past four years, scientists have designed robotic and automated systems capable of safely dismantling, sorting, and upcycling used lithium-ion cells. This process has traditionally been seen as labor-intensive and hazardous.

“We have developed innovative solutions that are attracting worldwide attention,” Andrea Vezzini, PhD, an industrial electronics professor at the Bern University of Applied Sciences (BFH) and project manager, said.

Automating safe recycling

Electric vehicles are crucial in the transition to cleaner transportation. Still, their batteries remain notoriously difficult to recycle. In 2019, global EV battery waste totaled around 500,000 tons, with scientists estimating it could increase to eight million tons by 2040.

That’s why, instead of treating them as waste, the Swiss research consortium set out to create a new circular process that extends battery life, enhances recycling efficiency, and minimizes environmental impact.

The robot-assisted recycling system was designed at the Swiss Battery Technology Center (SBTC) in Biel/Bienne. It uses precision robotics to separate battery modules and recover high-quality raw materials with minimal manual handling.

Nora Bartolomé (Empa) and Olivier Groux (Kyburz Schweiz AG) work together on recovering high-quality raw materials from lithium-ion batteries.

Nora Bartolomé (Empa) and Olivier Groux (Kyburz Schweiz AG) work together on recovering high-quality raw materials from lithium-ion batteries.

Credit: Innosuisse

“These solutions represent a first step on the way to closing the battery loop with stations distributed around the globe,’ Vezzini concluded in a press release.

Furthermore, the project also addressed battery life extension and reuse. The team also developed a “Battery Expert System” that can compare the aging patterns of thousands of cells. This tool helps engineers determine which cells can be repaired or repurposed.

According to the research team, some retired EV batteries can be converted into stationary energy storage systems. These can serve a second life as backup power units for buildings or renewable energy grids.

Sustainable battery reuse

To make these systems scalable, the researchers designed automated dismantling processes and direct material recovery methods. They also developed novel electrode coatings that reduce both energy consumption and production costs during cell manufacturing.

Together, these new approaches create a framework for integrating secondary raw materials into new batteries, marking a key step toward reducing dependence on newly mined materials.

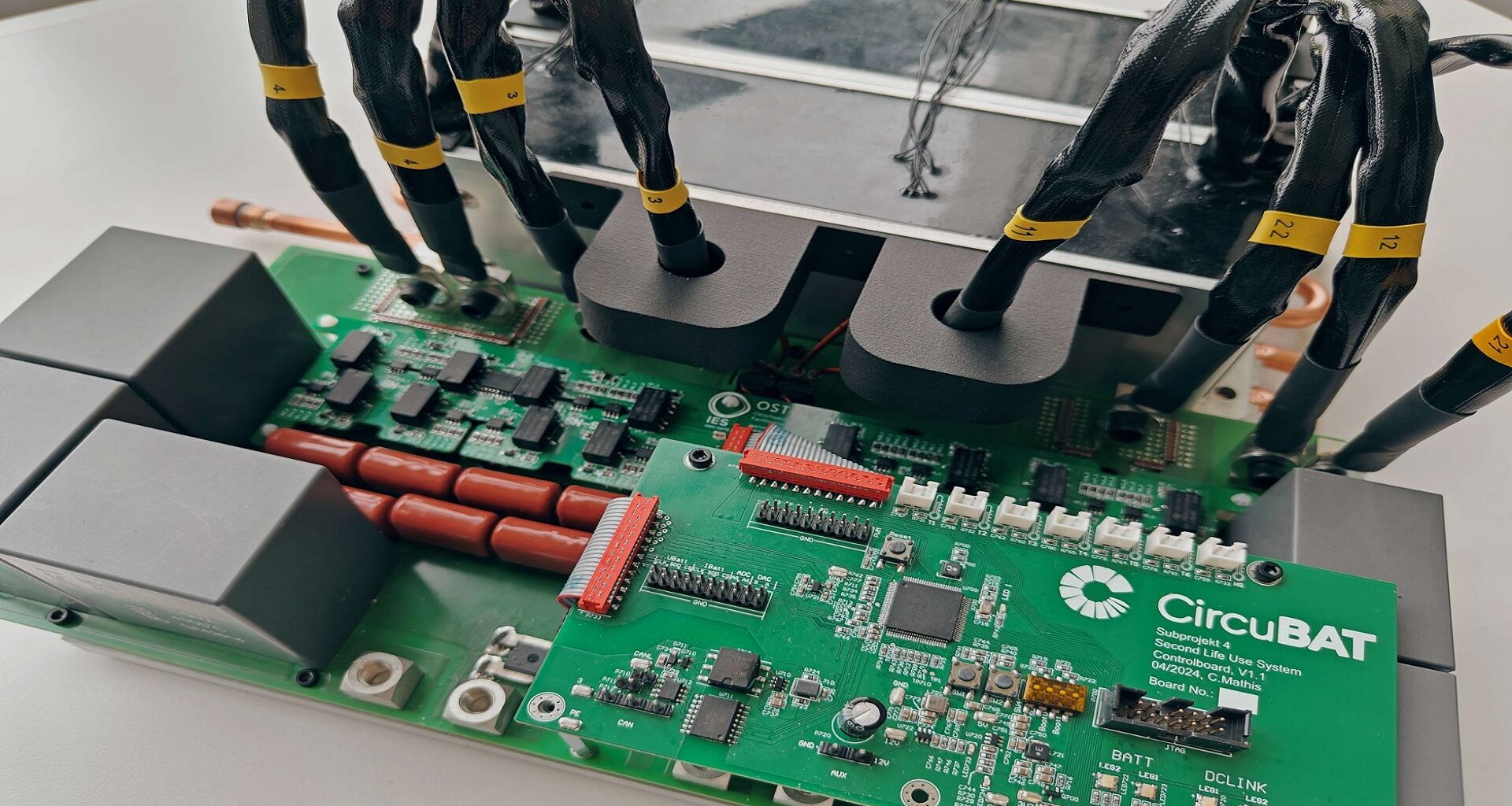

In future, robots will assist in the upcycling of Li-ion batteries. Tech development at the Swiss Battery Technology Centre (SBTC) at Switzerland Innovation Park Biel/Bienne. Credit: Innosuisse

In future, robots will assist in the upcycling of Li-ion batteries. Tech development at the Swiss Battery Technology Centre (SBTC) at Switzerland Innovation Park Biel/Bienne. Credit: Innosuisse

“In addition to these technical aspects, the project also developed the Swiss circular economy model for lithium-ion batteries, which will enable future volumes to be estimated, for example for the Swiss second-life battery market,” the experts elaborated.

They believe the findings could play a significant role in decarbonizing Swiss mobility. The results could also help accelerate the transition to renewable energy.

CircuBAT is part of the Flagship Initiative of Innosuisse, the Swiss Innovation Agency. The closing conference, CircuBAT2025, will take place on November 13 and 14 in the BERNEXPO Foyer. It will address the topic through the lens of science, politics, and society.