Trailer orders continued to be weak in August, a whopping 10,000 units off 10-year August norms.

With truck makers opening their 2026 order boards, the next few months will be critical, but significant headwinds remain.

And the spot market wiped out the Labor Day gains, but market demand improved since capacity was leaner.

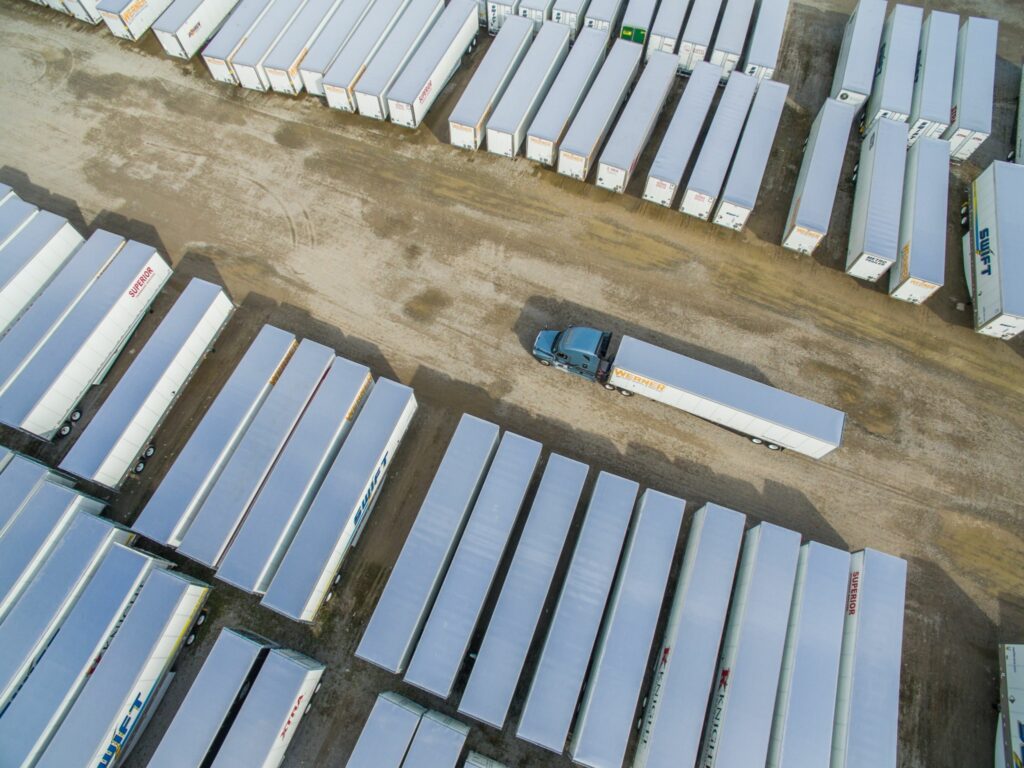

Trailer orders still weak

August trailer orders of 7,261 units were more than 10,000 off the 10-year August average of 17,568 units, according to the latest data from FTR.

Orders were down 4% from July but up 3% year over year. Cancellations remain above long-term norms but have come down from 39% in May to 16%.

“With builds continuing to outpace new orders, OEMs face mounting pressure to balance production against a thinning pipeline. Unless order activity strengthens with the opening of 2026 order boards, the industry may confront additional headwinds heading into next year,” said Dan Moyer, senior analyst, commercial vehicles with FTR.

“For trailer manufacturers and their suppliers, tariffs are producing costs, tighter margins, and increased risk of consolidation. Larger, integrated players are more resilient, while smaller firms are vulnerable. Many fleets are delaying replacements, relying more on used trailers and curbing expansion. The 2026 order season may start later than September for some OEMs with subdued bookings as policy uncertainty and structurally higher costs weigh on demand.”

ACT Research reported orders of 9,000 units.

“Sequentially, higher August net order intake was expected, as the annual cycle begins to move toward stronger order months at the end of Q3 when the industry begins opening next year’s order boards,” said Jennifer McNealy, director, commercial vehicle market research and publications at ACT Research.

“August’s tally brings the year-to-date net order total to 109,800 units, about 23% better than the same eight-month order intake of 2024. Looking forward, concern continues that moderating economic activity, ongoing weak for-hire carrier profitability, and ambiguous policy shifts remain as challenges to stronger trailer demand. Ongoing near-term uncertainty is why ACT’s expectations for subdued build and lackluster order intake levels during 2025 remain intact. Simply put, there isn’t enough impetus in the current hesitant environment to support a more robust outlook.”

Truck makers open ’26 order boards. What will order season hold?

ACT Research in its North American Commercial Vehicle Outlook report says the next three to four months will be critical for truck makers as uncertainty continues to cloud the market.

“On the tractor front, carrier profitability remains under pressure, inching closer to year four of the for-hire market downturn,” said Ken Vieth, ACT’s president and senior analyst.

“The group of publicly traded truckload carriers’ aggregated margins in Q2 were near 2008 recession levels, and the frontloading of goods ahead of tariffs in the first half of this year elevates the risk of a freight air pocket into the end of 2025. Additionally, while the U.S. consumer has remained resilient, signs of labor market weakness, and the fact that the full brunt of tariff costs has yet to be passed on to the consumer, are further risks to goods demand.”

There are also headwinds on the vocational front, ACT added. These include the end of any hopes of a pre-buy when EPA said it would review the EPA27 emissions rules.

“On top of regulatory matters, there are funding freezes delaying infrastructure project starts, despite Congress having already appropriated the funding. Lastly, deepening softness in housing and a construction pullback, solid freight generating segments, adds to vocational woes. Currently, elevated new home inventories are an added obstacle to recovery,” Vieth said.

“Vocational inventories are just off record levels, and backlogs are currently at five-year lows. Steep production cuts have already occurred to help alleviate backlog pressure, but elevated inventory remains a challenge for future production.”

Market demand improves to nine-week high, but spot rates slip

Spot market rates fell in the latest week ending Sept. 12, according to data from Truckstop.com and FTR Transportation Intelligence. No surprise, really, as van rates typically slide in the weeks following Labor Day, Truckstop.com reports.

Dry van rates remain higher than before the sharp pre-Labor Day increase, but a decline in reefer rates erased overall market gains.

“Refrigerated rates increased by just over 15 cents in the week immediately before Labor Day, on average, then dropped roughly eight cents during the Labor Day week, and fell just under nine cents last week,” Trucsktop.com reported.

“Flatbed spot rates declined after rising for the first time in nine weeks. Further decreases in van spot rates are typical into October, while flatbed rates usually start to settle after a gradual decline from levels in the middle of the year.”

With load postings in the week after the holiday outpacing truck postings, the Market Demand Index rose to 89.7 — the strongest level in nine weeks.