What is the Biomanufacturing Specialty Chemicals Market Size?

The global biomanufacturing specialty chemicals market is witnessing strong growth as pharmaceutical and biotech companies rely on specialized chemicals to support biologics and cell therapy production. This market is growing due to increasing demand across multiple end-use industries, rapid industrialization in emerging economies, and a global shift toward sustainable and bio-based products.

Biomanufacturing Specialty Chemicals Market Key Takeaways

Europe dominated the market, holding the largest market share of 55% in 2024.

Asia Pacific is expected to grow at a notable rate in market share.

By product type, the industrial enzymes segment held the largest share of the market at 32% in 2024.

By product type, the specialty enzymes segment is expected to grow at the fastest rate during the forecast period.

By feedstock, the sugar & starch segment held the largest market share of 40% in 2024.

By feedstock, the lignocellulosic biomass segment is expected to grow at the fastest rate during the forecast period.

By application, the pharmaceuticals segment held the largest share at 35% in 2024.

By application, the personal care & cosmetics segment is expected to grow at the fastest rate during the forecast period

By scale of production, the commercial scale segment is expected to grow at the fastest rate of 60% in the biomanufacturing specialty chemicals market.

By scale of production, the pilot scale segment held the largest share in the market in 2024.

By end user, the specialty chemicals manufacturers segment held the largest share at 48% in 2024.

By end user, the startups & SMEs segment is expected to grow at the fastest rate during the forecast period.

Market Overview

The biomanufacturing specialty chemicals market is witnessing steady growth as sectors move toward bio-based and environmentally friendly production techniques. Technological innovation in bioprocessing is being propelled by the growing demand in personal care, agriculture, and pharmaceuticals. An increasing number of businesses are spending money on R&D to improve the yield, effectiveness, and affordability of bio-based chemicals. Biomanufacturing is positioned as a major force behind the chemicals industry of the future, and this trend is in line with global sustainability goals.

In April 2025, IFF and Kemira announced the launch of AlphaBio, a joint venture for the commercial-scale production of renewable bio-based specialty materials. (Source: https://greenchemicalsblog.com)

Market Outlook

Industry Growth Overview: The market is steadily growing because of the growing need for bio-based sustainable chemicals in industrial, personal care, pharmaceutical, and agricultural applications. Enhancing efficiency and yield are developments in enzymatic processes, fermentation, and synthetic biology.

Sustainability Trends: To lessen their impact on the environment and satisfy consumer and regulatory demands, businesses are concentrating on waste valorization, green production technologies, and renewable feedstocks.

Global Expansion: Emerging markets in Asia-Pacific, North America, and the Middle East are driving growth, with governments supporting biotech infrastructure and increased adoption across industries.

Major Investors: Private equity, venture capital, and multinational chemical firms are investing in scalable bioprocessing, enzyme optimization, and pilot-to-commercial facilities to stay competitive.

Market Scope

Report Coverage

Details

Dominating Region

Europe

Fastest Growing Region

Asia Pacific

Base Year

2024

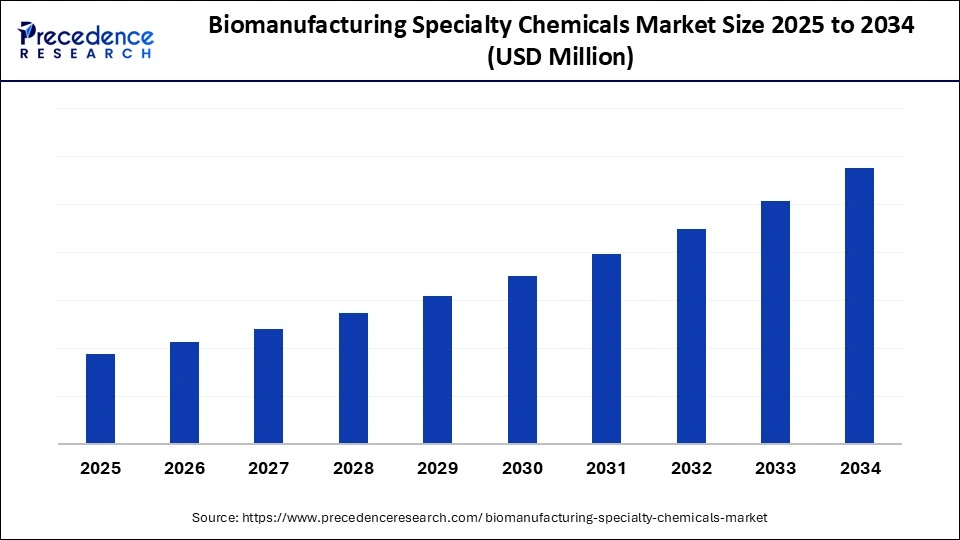

Forecast Period

2025 to 2034

Segments Covered

Product Type, Feedstock, Application, Scale of Production, End User, and Region

Regions Covered

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa

Market Dynamics

Opportunity

Sustainable Alternatives to Petrochemicals

Specialty chemicals derived from petroleum have a significant chance to be replaced by bio-based substitutes in industries like packaging, food additives, and cosmetics due to tighter environmental regulations and growing consumer demand for eco-friendly products. This change also helps businesses reach carbon-neutral goals and win over eco-aware customers.

Market Challenge

High Production Costs

Bio-based specialty chemicals are frequently still more costly than their petroleum-based counterparts, even with technological advancements. One of the biggest challenges facing manufacturers is increasing production while keeping costs competitive. Cost reduction requires ongoing investment in advanced biotechnologies and process optimization.

Regional Insights

Country-Level Investments & Funding Trends for Biomanufacturing Specialty Chemicals Market

Country

Investment Focus

Funding Objective

India

Strategic initiatives to strengthen the chemical industry through government policies & attract the chemical sector.

Expand biomanufacturing & specialty chemicals while strengthening manufacturing competitiveness.

Canada

Government-backed programs for next-gen biomanufacturing include the strategic innovation fund for expanding the country’s biomanufacturing.

Build capacity for advanced medicines and develop talent infrastructure in the life sciences sector.

United States

DoD-supported biomanufacturing projects are for the Department of Defense for national security and military applications. Ions.

Develop pilot & commercial-scale facilities to create resilient domestic production and strengthen the bioeconomy.

UAE

Industrial development initiatives such as “Operation 300bn,” which is a broad strategy to boost the country’s overall manufacturing sector.

Support chemical manufacturing & industrial growth by diversifying the economy and attracting investment in advanced manufacturing.

Segmental Insights

Product Type Insights

Why did the industrial enzymes segment dominate the market in 2024?

Industrial enzymes segment is dominating the biomanufacturing specialty chemicals market due to their extensive applications across food & beverages, detergents, textiles, and paper & pulp industries. Theor robust demand is driven by established industrial processes, cost efficiency, and proven effectiveness, making them the backbone of enzyme utilization in large-scale manufacturing.

Specialty enzymes are the fastest-growing segment in high-value industries like fine chemicals, biopharmaceuticals, and diagnostics. Higher specificity, stability, and efficacy are provided by these enzymes, which are designed for particular reactions nd support the expansion of specialized applications where accuracy is essential.

Feedstock Insights

Why did the sugars & starch segment dominate the biomanufacturing specialty chemicals market in 2024?

Sugars & starch remain the primary feedstock for specialty enzymes because they are readily available, cost-effective, and widely used in fermentation, biofuel, and food processing industries. Their predictable yield and established supply chains make them a staple in industrial enzyme production.

Lignocellulosic biomass is growing rapidly in the market, driven by the desire for second-generation biofuels and sustainability trends. Technological developments in pre-treatment and enzymes are opening their potential for large-scale production of specialty enzymes, and they provide a plentiful and renewable source.

Application Insights

What made the pharmaceuticals segment dominate the market in 2024?

Pharmaceutical applications currently dominate specialty enzyme usage, due to stringent regulatory standards and consistent demand for enzyme-assisted drug manufacturing, diagnostics, and vaccine production. Enzymes provide high specificity and efficiency, crucial for maintaining quality in pharmaceuticals.

Personal care & cosmetics are growing fastest in the market as skincare, haircare, and cosmetic formulas increasingly include enzymes, increasing consumer awareness and preference for sustainable, plant-based ingredients is propelling the industry’s adoption of enzymes, and the ability to tailor enzyme performance provides precise, targeted, and gentle solutions.

Scale of Production Insights

What made commercial scale dominate the market in 2024?

Commercial-scale production dominates the specialty enzyme market, supported by established infrastructure, large-scale bioreactors, and optimized downstream processing, and is increasingly leveraging genetic engineering to create custom enzymes with superior functionality and higher yields. This ensures consistent quality, high yield, and cost efficiency for mass production.

Pilot scale segment is growing rapidly in the market as small batch manufacturing and innovative enzymes are tested by startups and research-driven businesses, who test innovative enzymes through small-batch manufacturing, while pilot plants enable quick iterations, creativity, and flexibility before scaling up.

End User Insights

Why did specialty chemicals manufacturers segment dominate the market in 2024?

Specialty chemicals manufacturers segment is dominating the biomanufacturing specialty chemicals market as they are the largest consumers of enzymes for chemical synthesis, biotransformation, and industrial processes. Their established demand and integration into production chains solidify their leading position.

Startups & SMEs are growing rapidly by utilizing enzymes for cutting-edge uses in biopharmaceuticals, green chemistry, and functional foods. Smaller players can quickly adopt specialized enzymes thanks to agility and niche targeting, enabling the quick and precise development of specialized enzymatic solutions.

Regional Insights

What made Europe dominate the market in 2024?

Europe dominates the specialty enzymes market due to advanced biotechnology infrastructure, stringent regulations promoting quality and sustainability, and the presence of major enzyme manufacturers. The region also has strong adoption across pharmaceuticals, food, and industrial sectors.

Asia Pacific is the fastest-growing market, fueled by increasing industrialization, rising demand for bio-based products, and government support for biotechnology initiatives. Growing pharmaceutical, food, and personal care industries are accelerating enzyme adoption due to the expansion of pharmaceutical, food, and personal care industries, coupled with a focus on sustainable manufacturing processes.

Biomanufacturing Specialty Chemicals Market Companies

BASF SE: A global leader in chemicals with a significant bio-based division.

Corbion: A Dutch company focused on bio-based ingredients, known for its expertise in fermentation.

DuPont: A major player in bio-based chemicals and industrial enzymes.

Evonik Industries AG: A German specialty chemicals company that leverages biotechnology for sustainable products.

International Flavors & Fragrances (IFF): A prominent producer of bio-based flavors and fragrances.

Novonesis: The company formed from the merger of Novozymes and Chr. Hansen specializes in enzymes and microbial solutions.

Recent Developments

In September 2025, FUJIFILM Biotechnologies celebrated the grand opening of its commercial-scale cell culture manufacturing site in Holly Springs, North Carolina, marking one of the largest biomanufacturing facilities in North America. (Source: https://www.fujifilm.com)

In April 2025, BioMADE announced the launch of a demonstration-scale biomanufacturing facility in Maple Grove, Minnesota, backed by a $132 million investment, to support scale-up of bio-industrial processes. (Source: https://www.biomade.org)

Segments Covered in the Report

By Product Type

Enzymes

Industrial Enzymes (detergents, textiles, pulp & paper)

Food Enzymes (bakery, dairy, brewing)

Pharmaceutical Enzymes (therapeutic, diagnostic)

Specialty Enzymes (research, niche industrial use)

Amino Acids

Essential Amino Acids (lysine, methionine, threonine, tryptophan)

Non-Essential Amino Acids (glutamine, glycine, alanine)

Specialty Amino Acids (D-amino acids, cysteine derivatives)

Organic Acids

Citric Acid

Lactic Acid

Succinic Acid

Itaconic Acid

Other Niche Acids (gluconic, fumaric, malic)

Biopolymers

Polylactic Acid (PLA)

Polyhydroxyalkanoates (PHA)

Starch-Based Polymers

Other Specialty Biopolymers (chitosan, alginate derivatives)

Biosurfactants

Rhamnolipids

Sophorolipids

Mannosylerythritol Lipids (MELs)

Other Emerging Biosurfactants

Bio-Solvents

Ethanol

Butanol

Acetone

Glycerol Derivatives

Others

By Feedstock

Sugars & Starch

Lignocellulosic Biomass

Algae

Glycerol

Waste Streams

By Application

Pharmaceuticals

Food & Beverages

Agriculture

Personal Care & Cosmetics

Industrial Chemicals

Textiles

Environmental Applications

By Scale of Production

Laboratory Scale

Pilot Scale

Commercial Scale

By End User

Specialty Chemical Manufacturers

Contract Manufacturing Organizations (CMOs)

Research Institutes

Startups & SMEs

By Region

North America

Europe

Asia Pacific

Latin America

Middle East & Africa