Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

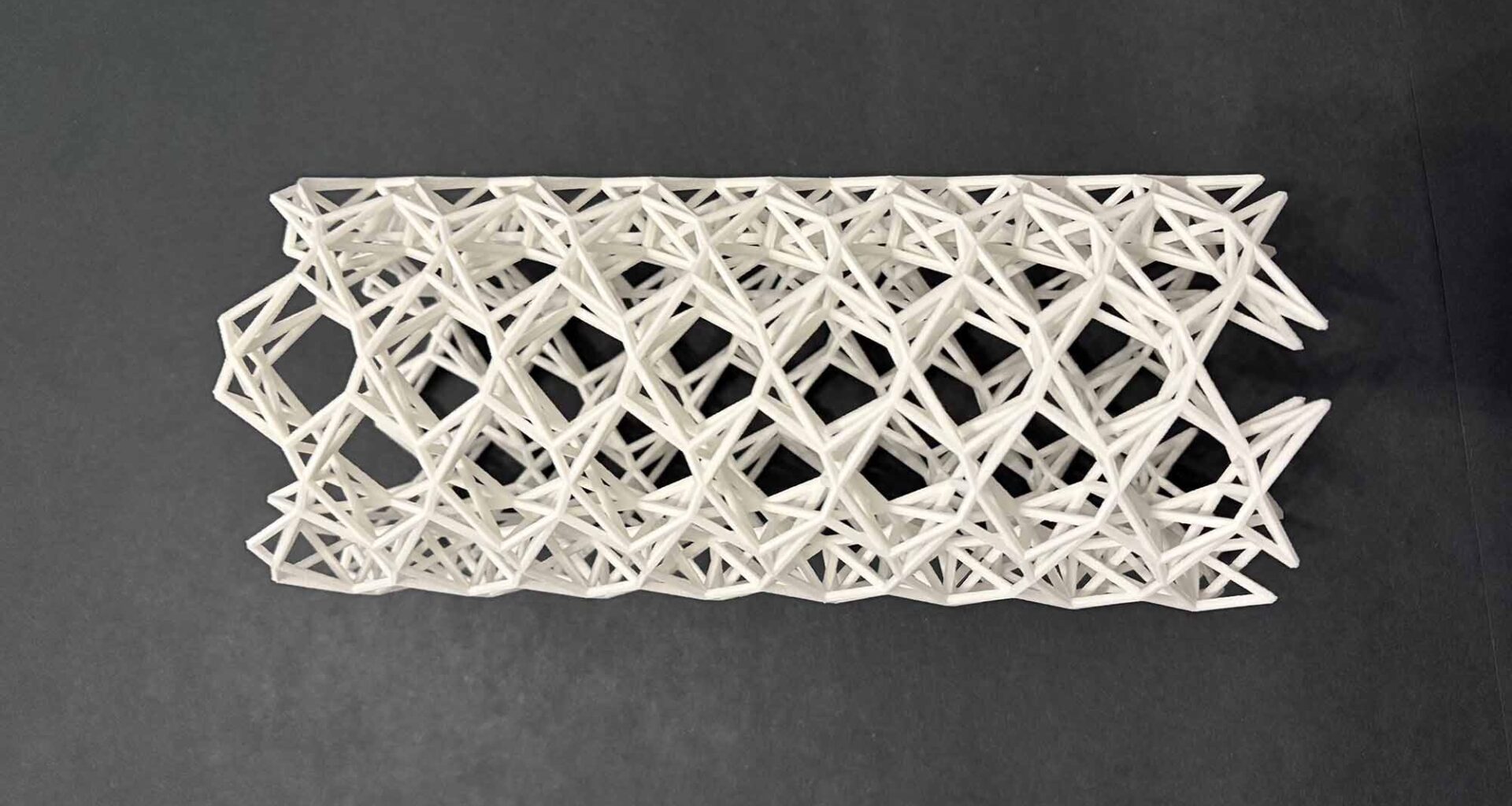

According to the University of Michigan (UM), researchers have developed a new approach to vibration isolation that could be used to absorb shocks in vehicles, buildings, and other structures. The team, working with the Air Force Research Laboratory (AFRL), demonstrated how 3D printed mechanical metamaterials – structures whose geometry, rather than composition, determines their properties – can block vibrations through their intricate internal design.

The study, published in Physical Review Applied, translates decades of theoretical work into a tangible breakthrough. “That’s where the real novelty is. We have the realization: We can actually make these things,” said James McInerney, research associate at AFRL and former postdoctoral fellow at the University of Michigan. “We’re optimistic these can be applied for good purposes. In this case, it’s vibration isolation.” The project received federal support from DARPA, the Office of Naval Research, and the US National Research Council Research Associateship Program.

Co-authors include UM mechanical engineering professor Serife Tol, Othman Oudghiri-Idrissi of the University of Texas, and AFRL researchers Carson Willey and Abigail Juhl. “For centuries, humans have improved materials by altering their chemistry. Our work builds on the field of metamaterials, where it is geometry – rather than chemistry – that gives rise to unusual and useful properties,” said U-M physicist Xiaoming Mao. “These geometric principles can apply from the nanoscale to the macroscale, giving us extraordinary robustness.”

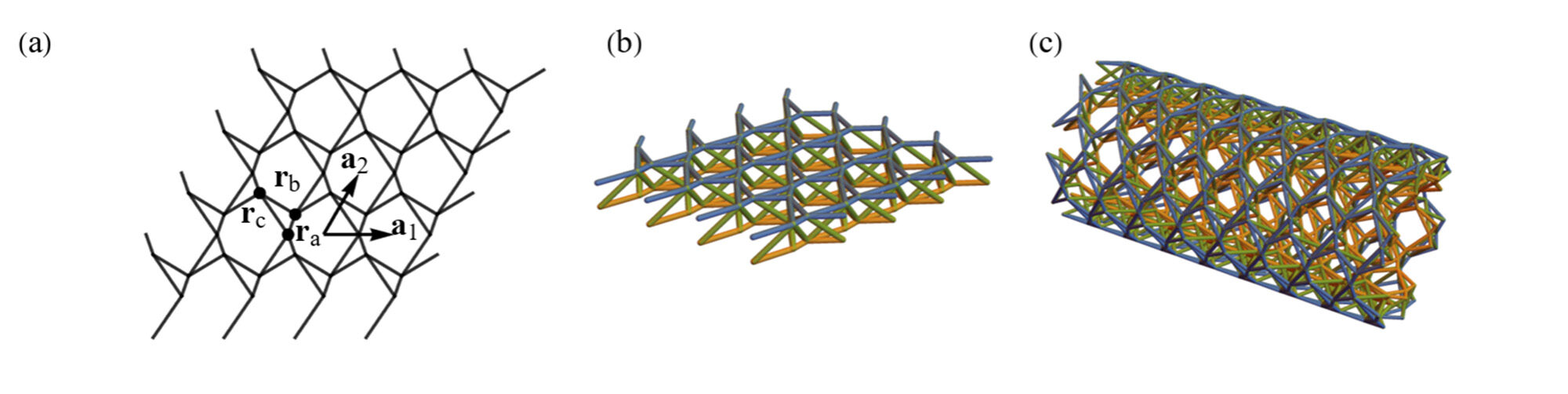

The vibration-isolating structures can be thought of as being built up from a repeating lattice (a) that’s then stacked into two layers (b) and wrapped into a tube (c). Image credit: J.P. McInerney et al.

The vibration-isolating structures can be thought of as being built up from a repeating lattice (a) that’s then stacked into two layers (b) and wrapped into a tube (c). Image credit: J.P. McInerney et al.

The research merges classical structural engineering, modern physics, and advanced 3D printing. Using geometrically tuned designs, the team printed ‘kagome tubes’ – complex, rolled lattice structures inspired by Japanese basket weaving – that effectively suppress vibrations traveling along their length. Such precision geometry allows ordinary materials like nylon or metal to exhibit entirely new mechanical behaviors.

This geometric strategy echoes nature’s own solutions, such as the architecture of bones or plankton shells, which achieve strength and resilience through structure. “The idea isn’t that we’re going to replace steel and plastics, but use them more effectively,” said McInerney.

The work draws on historic ideas, including James Clerk Maxwell’s 19th-century studies of stable lattices and modern discoveries in topological physics, which describe how unusual behaviors arise at material boundaries. Building on these principles, the team created physical metamaterials that demonstrate ‘topological phases’ capable of damping vibrations.

McInerney noted that while the current prototypes highlight tradeoffs – better vibration isolation reduces load-bearing capacity – the findings open new directions for testing and design. “Because we have such new behaviors, we’re still uncovering not just the models, but the way that we would test them… before we start answering questions about applications,” he said.