A novel technique developed by South Korean and U.S. researchers could one day provide a more effective treatment for complex bone fractures.

A Biocompatible Thermoplastic

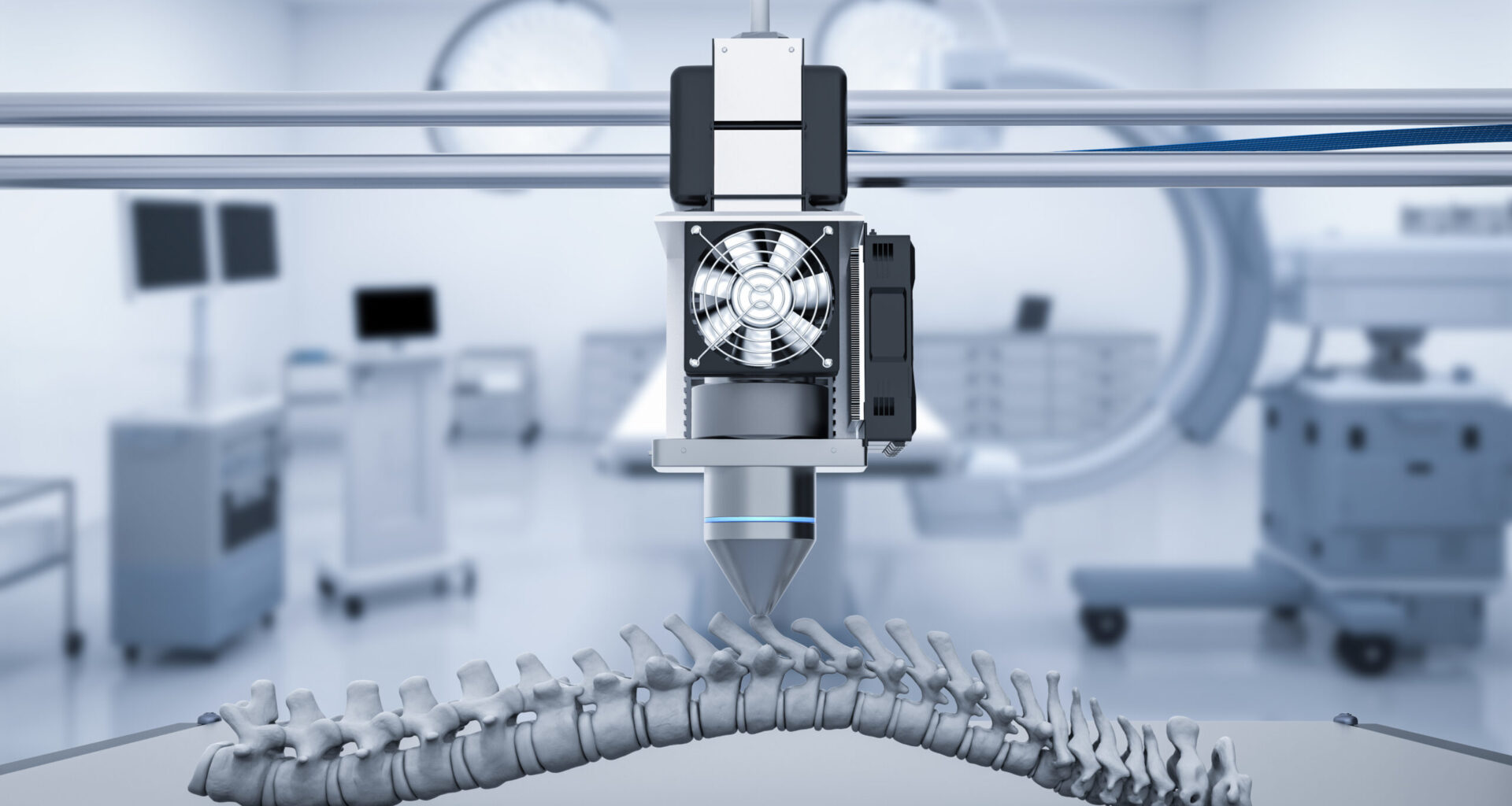

A team of engineers from universities in both nations successfully modified a glue gun to create a 3D printing device that can apply bone grafts directly onto bones during surgery.

The modified glue gun dispenses a filament containing hydroxyapatite, which promotes bone healing, and polycaprolactone, a biocompatible plastic. When applied using heat, the material conforms to fractures without damaging surrounding tissue. The team has already successfully tested this method on rabbits.

Real-Time Fabrication and Application

While current bone implants can be made from 3D-printed materials — alongside traditional options like donor bone and metal — they typically need to be custom-designed to fit irregular fractures. This process often requires preoperative steps like modeling, imaging, or trimming.

The modified glue gun, however, enables real-time fabrication and application during surgery, eliminating the need for time-consuming prefabrication procedures.

Incorporating Antibiotic Properties

The engineers also designed the 3D-printed material to provide structural flexibility, promote natural bone regrowth, and release antibiotics to help reduce the risk of infection after surgery.

Looking ahead, the team plans to further optimize the material’s antibiotic properties and prepare the technique for human trials.

Find Thomasnet Suppliers and Services

Image Source: Shutterstock / Phonlamai Photo