Welcome to the future, where we have two existential problems we simply can’t get rid of: the atmosphere is full of carbon dioxide, and plastic waste is freaking everywhere. Now, though, researchers from the University of Copenhagen have come up with a two-in-one breakthrough that uses one problem to solve the other – by transforming plastic trash into a material that can absorb CO2 out of the air so well it already compares well with some of the carbon capture tech out there.

The rest of this article is behind a paywall. Please sign in or subscribe to access the full content.

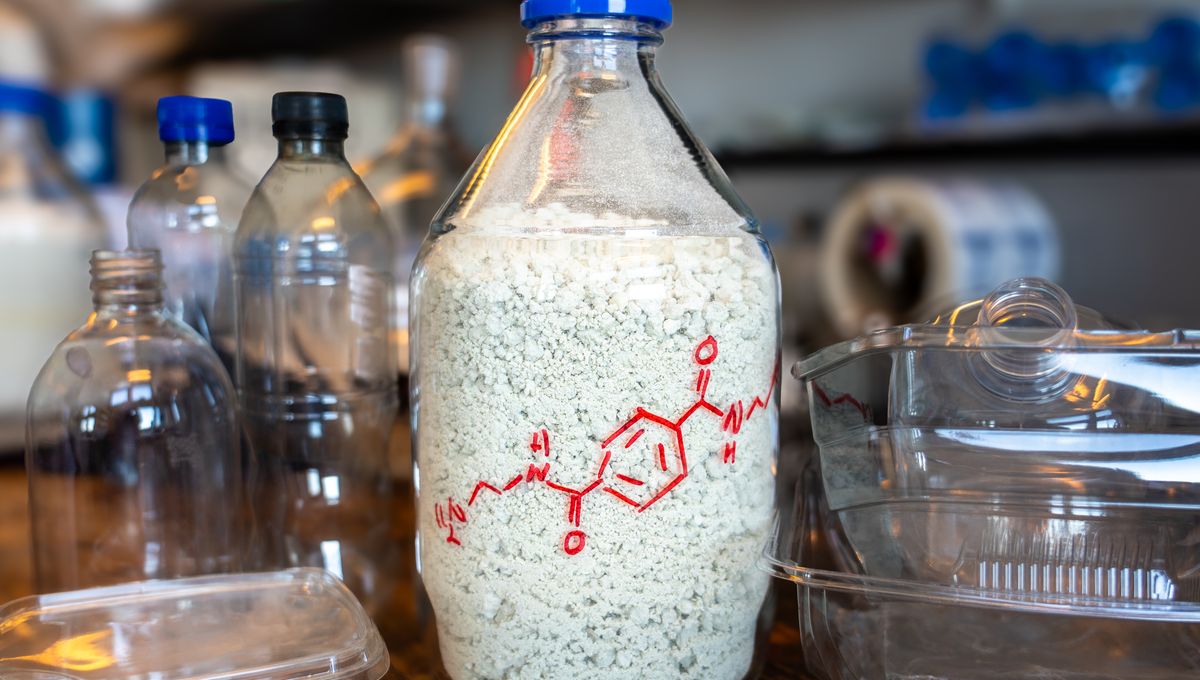

“The beauty of this method is that we solve a problem without creating a new one,” said Margarita Poderyte, a PhD fellow in the University of Copenhagen’s Department of Chemistry and lead author of a new paper describing the invention – a powdery material which the team have named BAETA.

“The main ingredient is plastic waste that would otherwise have an unsustainable afterlife,” she explained in a statement Friday, “and the synthesis we use, where the chemical transformation takes place, is gentler than other materials for CO2 capture because we can make the synthesis in ambient temperatures.”

That makes it easy to accommodate – no ultra-cold or highly pressurized environments needed for this miracle invention. “It works efficiently from normal room temperature up to about 150 degrees Celsius, making it very useful,” pointed out Jiwoong Lee, Associate Professor at the Department of Chemistry and co-author of the paper.

That kind of range is “very useful,” Lee said. “With this kind of tolerance to high temperatures, the material can be used at the end of industrial plants where the exhausts are typically hot.”

Once saturated, BAETA can be treated with a heating process to release the collected carbon, and no, that’s not just undoing all that good work we just carried out – that carbon can be concentrated and stored in things like carbonated cement or fuel and fizzy drinks, or whatever else science comes up with in the future.

“We see great potential for this material,” Poderyte said. “The next big step is scaling up to produce the material in tonnes, and we’re already working to attract investments and make our invention a financially sustainable business venture.”

While questions abound over whether carbon capture technology is as effective an anti-emissions measure as is sometimes claimed, this new material has two big differences from industrial scale facilities. Firstly, it can be incorporated into existing emissions sources rather than simply hoping to catch it out of the surrounding air. Secondly, its very creation tackles another problem: plastic waste, which otherwise would disintegrate down into the microplastics that plague environments from the outside world to the blood inside our bodies.

“By turning waste into a raw material that can actively reduce greenhouse gases, we make an environmental issue part of the solution to the climate crisis,” Poderyte explained. For example, she said, “if we can get our hands on the highly decomposed PET plastic floating in the world’s oceans, it will be a valuable resource for us as it’s so well suited for upcycling with our method.”

“We’re not talking about stand-alone issues, nor will the solutions be,” agreed Lee. “Our material can create a very concrete economic incentive to cleanse the oceans of plastic.”

The study is published in the journal Science Advances.