In space, manufacturing has always been an area with much speculation but little actual progress. The idea is simple: zero or reduced gravity environments may be a better place to manufacture certain things. Perhaps fiber optic cable, heart valves, or semiconductors would be made with fewer errors and higher purity. Despite a lot of investment and a reduction in launch costs, little actual viable manufacturing has been done to date.

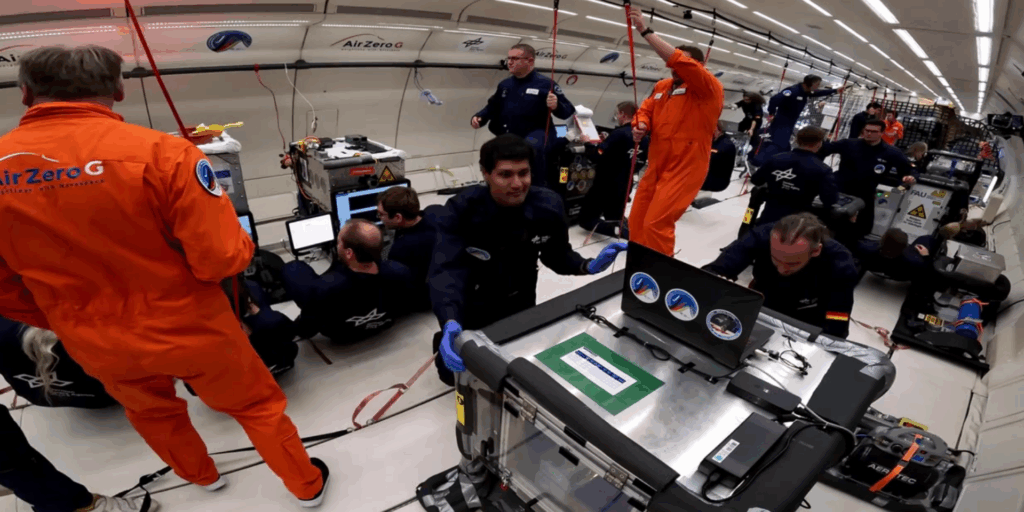

But, not for want of trying. Now ETH Zurich has hit the vomit comet to manufacture muscle tissue. Brave researchers, on empty stomachs, one would assume, have used a 3D printer to make 2.5D mouse muscle tissue (thin-layered samples rather than full 3D structures). The team hopes that this technology could be used by space travelers to battle space conditions such as muscle atrophy caused by space travel, and also thinks that it could make “more realistic muscle models that reflect how tissue truly behaves in space.”

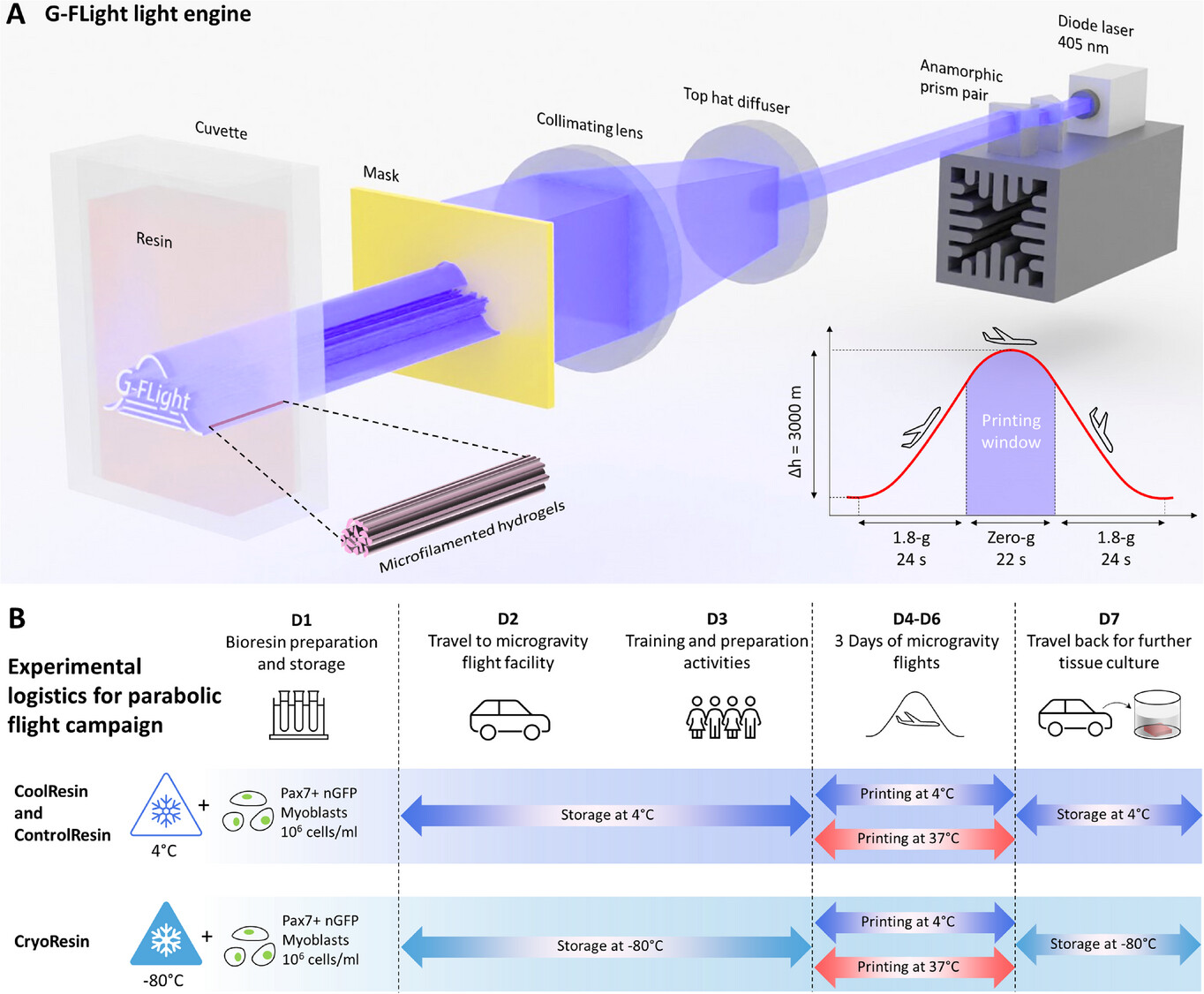

Optical components of G-FLight printer and resin formulations.

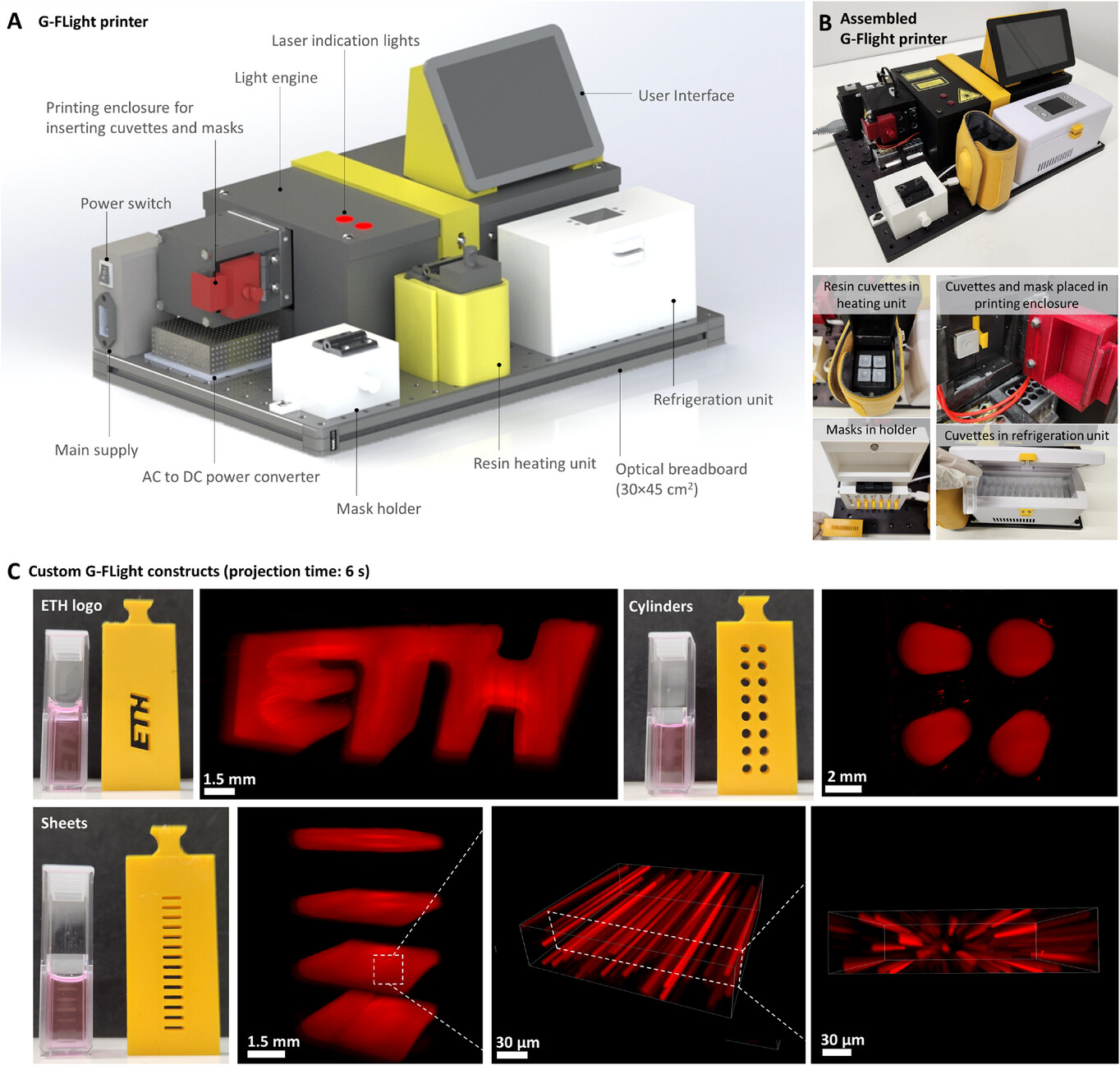

The work published in Wiley Advanced Science is titled “Prolonged Cell Encapsulation and Gravity-independent Filamented Light Biofabrication of Muscle Constructs.” Will this be a solution if Jeff Bezos twists his ankle golfing on Mars, or will there be wider ramifications? Could perhaps the stay-behinds benefit too? We don’t know yet, but the team has created its own G-FLight printer for FLight printing. This 405 nm LaserTrack diode laser-powered unit was specifically made to print with microfilamented hydrogels. The resin is a gelatin methacryloyl resin, GelMA.

The team also made custom resin formulations and had to work out how to keep the resin at 4°C and print at 4°C (as a gel) and 37°C as a liquid, while another Cryo resin was stored at -80°C and printed at 4°C. The team created a freezer unit to keep the resin frozen on board, Mr. Frosty. They also integrated a baby bottle warmer to warm up resins. The tissues were printed in cuvettes, similar to how Xolo does it, and then driven back to Zurich.

To keep the printer simple, they used a cut-out mask, which means that they can only print one repeated shape, very limiting indeed, but it did keep the printer safer and simpler. The prints, therefore, were 2.5D. The team believes that the structure they created on the comet was the same as those made back on Earth. Bad news for the stay-behinds, therefore, but good news for Jeff.

G-FLight printer and example prints of microfilamented constructs.

Besides a new meniscus for potentially literal plutocrats, the team thinks they may be able to 3D print meat or actuators made from human tissue. The team also thinks that they may be able to 3D print tendons or cartilage, so there could be no impediment at all to treating any and all space billionaires’ space-sustained sports-related injuries. Play hockey, Jeff, try squash. For now, they used mouse myoblasts, and I really hope the mice are grateful for all the work we’re doing for them. But, perhaps they’ll be about as happy as rabbits are with their endless shampoos and lipstick.

Reimagining a space manufacturing device as simple as this one to quickly print structures is an interesting exercise. Perhaps for certain things, such as Big Macs for astronauts, or skin tissue, monomers, proteins, a long repetitive print of the same structure could actually be a solution in and of itself. The frugality of this and the way it should stand up to knocks and launches are a result of its simplicity. The cuvettes approach also reduces a lot of sloshing around danger as well. So there’s quite a bit here to learn. But for in-space manufacturing, other bioprinters are much more versatile and complete devices, though. We’ve seen quite a bit of bioprinting in space adventures with Redwire 3D printing a meniscus in 2023. Belgian researchers are trying to print heart tissue in space, and Auxilium Biotechnologies has officially launched a clinical trial of its NeuroSpan Bridge implant. Most in space systems are made with material extrusion, but Photocentric has a spinning LCD system, which makes polymer parts. With so much going on, it’s tempting to see a gold rush forming. However, so far, speculation and hope are fueling these developments. Unlike the space launch or satellite array business, there is no yet workable business model for in-space manufacturing. Perhaps ETH’s simpler approach could make smaller, more inexpensive machines that are cheaper to fly. That could make it cheaper to run experiments that may lead to a viable in-space business that could propel research toward commercialization.

Images courtesy of ETH Zurich / Wiley Online Library

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Upload your 3D Models and get them printed quickly and efficiently.