Copper cabling has been the workhorse for moving data inside of AI and HPC data centers, but fiber is nipping at its heels.

Optics brings three possible bandwidth multipliers — wavelength-division multiplexing (WDM), the use of different modes, and polarization. Each has a role in longer-distance optical links, but the tradeoffs are different in the data center. WDM appears poised to boost bandwidth, while the other options are harder to implement and may not be necessary yet.

Bandwidth multipliers

The simplest optical signal is a coherent laser beam that has been modulated prior to transmission. For this setup, the bandwidth is determined by the modulation. The light beam acts as the carrier for the signal. That beam itself has a frequency separate from the bandwidth.

Unlike electronics, where clock frequencies are king, the optical part of the industry invokes the inverse — the wavelength, often called the lambda (λ). The lambda of a given fiber implementation is chosen both for compatibility with a laser source and the transmission characteristics at that lambda, since various loss mechanisms are wavelength dependent. Strictly speaking the lambda is unrelated to the bandwidth, as with AM or FM radio, where the carrier frequency is unrelated to the frequency of the content. But that assumes the lambda is much higher in equivalent frequency than the bandwidth.

With this foundation, three phenomena allow that bandwidth to be multiplied by some integer:

WDM replicates the setup on multiple lambdas in a single fiber. “In the same fiber, you can stuff more bits,” explained Priyank Shukla, director of product management, interface IP at Synopsys. “You don’t need to have multiple parallel fibers.” This creates different channels on different colors, and the multiplier is the number of colors employed.

Light in some fibers can “vibrate” in different modes, much the way a guitar string, trumpet, or Chladni plate does. If different modes can be independently modulated, then each mode becomes a channel. The bandwidth is then multiplied by the number of modes employed.

Two polarizations are possible, called transverse electric (TE) and transverse magnetic (TM). If each is modulated separately, this can double the bandwidth.

Modes, polarization get messy

Using modes requires multimode fiber, which has a larger diameter (> 50µm) than a single-mode fiber (~10 µm). The larger “tube” allows more modes to propagate. Because it’s a bigger fiber, it’s easier to get light into and out of it, so less costly sources and receivers can be used. This is sometimes employed in the data center using VCSELs as sources for very-short-reach links.

“You excite light in different fashions, so you’ll have waves in different modes,” said Shukla. “This means in the same fiber, you can stuff more data. VCSELs work really well with multimode fiber, and VCSELs are arguably the cheapest technology.”

But the modes aren’t mutually independent. “If I send light into a multimode fiber and let it propagate for a long time, under many perturbations and environmental interactions, eventually the population of light across the spatial modes of that optical fiber will follow a Bose-Einstein distribution, and there will be coupling and scattering between the different modes,” explained Nick Harris, CEO of Lightmatter. “So if I’ve really carefully encoded a signal in these modes, I just scrambled it across everything, and I don’t know how to undo it.”

That suggests WDM as a more robust way to boost bandwidth without garbling things beyond some distance. “Once you start going to WDM, you start seeing more single-mode fiber,” said Shukla.

The modes also must be independently modulated. “Mode multiplexing is really painful because the demux for that is incredibly difficult to do,” said Tapa Ghosh, founder and CEO of Volantis Semiconductor.

In addition, VCSELs are less linear than other lasers, making them harder to compensate. “With single-mode fiber, you can drive it with different kinds of lasers, such as a directly modulated laser (DML), and they are easier to compensate,” noted Shukla.

Polarization, meanwhile, suffers from some of the same issues. In particular, the TE and TM signals have different speeds, creating a challenge at the receiving end. “Most optical systems are not polarization-independent,” said Ghosh. “Certainly, waveguides are not. TE and TM modes have propagating polarization directions, different losses, and different refractive indices. And grating couplers are not polarization independent.”

“You want to use these extreme multiplexing techniques when you’re running a fiber across the country or under the ocean because that fiber is insanely expensive,” said Harris. The extra effort is necessary for employing modes, and polarization can make sense there. But it’s harder to defend in the data center, where fiber can be cheap and plentiful.

WDM gets easier

WDM has largely been eschewed in the data center, with single-mode single-color fiber (or multimode fiber for very short reaches) dominating. Part of the holdup has been the cost of implementing WDM. Each color requires its own laser, and the light from each laser must be fed into the same fiber. “With most architectures, you need some sort of interleaver, and that’s already around three times the energy of our entire link, end to end,” said Ghosh.

Today’s modulation techniques involve either Mach-Zehnder modulators (MZMs) or electro-absorption modulators (EAMs). “These are made from lithium niobate or other material systems,” explained Harris. “They’re not wavelength selective at all. They cannot tune anything, so you have to pair them with these very lossy and large mux circuits.”

What’s changed

The emergence of micro-ring resonators is a means of modulating and demodulating the individual colors in a WDM signal. These rings are small, and each can be tuned to a different color.

“We use micro-ring modulators,” said Harris. “That modulator is serving two purposes. It’s both doing the mux and demux and encoding the data. So you don’t need a separate mux and demux. It’s already built into the device that does the modulation.”

Two controls are necessary on a micro-ring resonator: one for modulating the light and one for tuning and stabilizing the wavelength. “One of them is used for encoding data, and it’s very fast — at like 50+ GHz,” said Harris when describing Lightmatter’s solution. “The other one is very slow, and it’s used to react to changes in the environment. We use it to control the ring for stabilization.”

Modulation is achieved using plasma dispersion. “Plasma dispersion is based on the physics of electrons and holes getting in the optical path,” said Harris. “Effectively, it looks like a diode that’s in the ring, and this is a well-understood industry principle.

As to how the electronics interface with the modulator, “A SerDes will directly drive its output into the high-speed input of the ring,” Harris added.

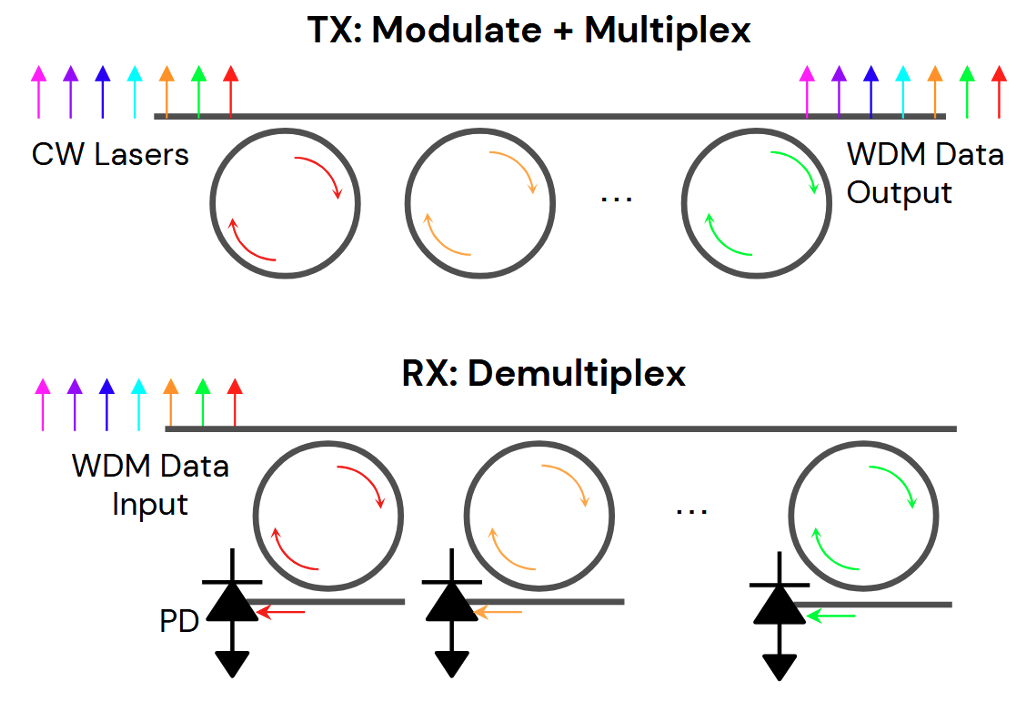

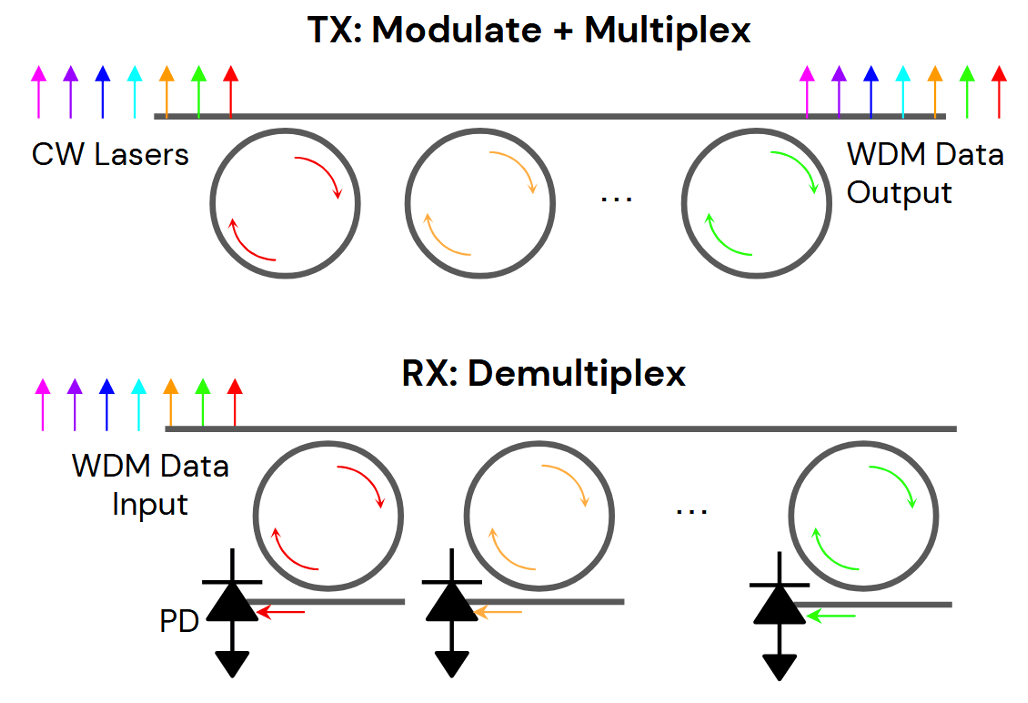

As shown in Figure 1, when transmitting, an unmodulated continuous-wave beam with multiple colors passes the micro-rings. Each micro-ring taps its color off the main beam, modulates that color, and then places it back into the beam. As a result, they perform both modulation and multiplexing, eliminating the need for separate components for these functions.

Fig. 1: At transmission, micro-rings both modulate each color and multiplex the colors together into one beam, and once received, the colors are separated into different signals. Source: Lightmatter

On receipt, the modulated signals move past the micro-rings, and each one pulls its color from the received beam. The micro-rings thus serve to demultiplex the WDM beam, sending each signal to its appropriate destination.

This arrangement makes for lower-power data movement. “The link, including everything —the lasers, the serdes, all of Lightmatter’s photonics — amounts to 4.6 pJ/bit,” said Harris. “Pluggable transceivers use 15 to 20 pJ/bit, so that’s a 3 to 4× total power savings.”

WDM guardbands

WDM refers generically to the use of multiple colors in a laser beam. What’s being discussed today for the data center typically qualifies as coarse WDM (CWDM), because the number of colors is limited. It typically tops out in the teens. Dense WDM (DWDM) can place many more colors — perhaps more than 100. This is made possible by narrowing the frequency width of the channels to fit many more channels into the same frequency range.

Given the amount of fiber moving into the data center, the most cost-effective approaches will appeal the most widely used. DWDM is more expensive to build, and given that data centers haven’t been deploying WDM at all so far, it’s probably not necessary. Several companies are working on data-center WDM, including Ayar Labs, Lightmatter, and NVIDIA, all of which presented their work at the recent Hot Chips conference.

One of the challenges with WDM relates to laser stability with respect to temperature. Typical installations have separate lasers for each color. But each of those lasers may drift slightly toward one or the other neighboring color, and they will each drift independently. For that reason, the channel wavelength windows include guardbands to keep the colors from drifting into each other.

Comb lasers have sometimes been discussed as a solution to this problem, because they generate all the colors from one source. That means that if they drift, they all drift together, making it possible to reduce some of the guardbanding and turn it back into usable bandwidth.

The challenge with combs, however, is efficiency. “Combs are not a good idea,” said Harris. “The reason is there’s a very low conversion efficiency from wall plug to light out. You’re better off putting a multiplexer after an array of lasers.”

It is possible, however, to actively control and stabilize independent lasers to reduce their drifting. Lightmatter does this with its Guide laser source. “The lasers are all actively controlled, monitored, stabilized, and they’re integrated,” said Harris.

Reliability, however, remains an issue. “When you heat up a laser, the FIT [failures in time, a reliability metric] rate gets a lot worse,” explained Harris. “You also want it to be replaceable if it fails.”

This drives decisions regarding where the lasers will be located. Most views of co-packaged optics (CPO) today have lasers installed outside the packages to boost their stability by isolating them from the heat of the dies in the package and to make them replaceable if they fail. A fiber then brings that laser light into the package. Such a scenario works for WDM since all colors come on a single fiber.

If CPO eventually places laser sources inside the package, WDM becomes much more difficult because all colors would require lasers in the package. In that case, a single color is easier to manage. “A single color is what we see that it makes sense from the packaging side,” said Andy Heinig, group leader, advanced system integration, department head for efficient electronics at Fraunhofer IIS’ Engineering of Adaptive Systems Division. That implies a large reduction in bandwidth as a cost of moving the lasers into the package. It may become yet another reason to keep the lasers separate.

Coming in a few years, but not to all data centers

WDM for the data center is actively being designed for deployment in 2027 or 2028. Although it can be employed for any data center workload, it makes sense today primarily for HPC and AI. While this is where today’s focus is, it can migrate into other data centers in the future if bandwidth demands it. For now, most data centers will stick with copper for as long as they can, and wherever they can.

Bandwidth needs are certainly growing, but it’s not the main limiter for more prosaic cloud applications. It is definitely a limiter for HPC and AI. WDM has been proven out with eight colors, and companies are poised to implement 16, which would be a sixteen-fold jump in bandwidth made possible by WDM alone. For this reason, modes and polarization aren’t really necessary yet — fortunate since they’re harder to implement.

Copper also remains easier to design with because most design tools focus on silicon and metal, not photonics. High-quality design requires the configuration of waveguides and photonic components, as well as verification of signal quality through the waveguides. WDM means verifying multiple signals in the same waveguide, not just one.

“We are working more and more to develop tools that allow us to design on the photonic side, taking into account the electronics,” said Sandra Gely, senior manager, application engineering at Ansys, now a part of Synopsys. “And we also have tools that help with connectivity so that when you want to connect from the chip to a fiber, you can make sure you don’t lose any signal.”

Modes and polarization certainly could bump optical bandwidth some more, but WDM has bought a lot of breathing room. If it runs out of steam, other multipliers may get a chance to shine.

Related Reading

Co-Packaged Optics Reaches Power Efficiency Tipping Point

But blazing fast data speeds come with significant manufacturing challenges.

Silicon Photonics Manufacturing Ramps Up

The promise of photonics ICs is spurring innovation, but complex processes and a lack of open foundries are keeping it from reaching its full potential.

Can Cheaper Lasers Handle Short Distances?

VCSELs may serve in more non-photonic applications.