Support CleanTechnica’s work through a Substack subscription or on Stripe.

Mass timber has moved far beyond the novelty stage. Cross laminated timber and glulam started to gain attention a decade ago as materials that could replace concrete and steel in mid-rise buildings. Since then the technology has advanced, codes have adapted, and architects and engineers have pushed the limits of what can be built with wood. Today the most interesting structures are not just apartment blocks or office mid-rises but skyscrapers, cultural landmarks, bridges, and even wind turbine towers. The diversity of projects tells a story of an old material reimagined for a low carbon future.

This is one of the last articles in my series examining the role of mass timber in Canada’s housing and climate future, and by extension the rest of the world. The first piece laid out Canada’s timber moment, framing cross-laminated timber (CLT) and modular construction as the fastest lever for addressing housing shortages, jobs, and embodied carbon. The second explored how Mark Carney’s housing initiative could industrialize the sector through pre-approved designs, offtake contracts, and regional factories. The third explored the requirement for vertical integration within the industry to maximize efficiencies. The fourth showed how CLT displacement could bend the demand curves for cement and steel, making their decarbonization pathways more realistic. The fifth demonstrated that from harvest to housing, CLT already locks away more carbon than it emits, strengthening its climate case.

The sixth turned to the forestry supply chain, arguing that electrification of harvesting, transport, and processing is essential to maintaining CLT’s carbon advantage. The seventh piece addressed systemic barriers, focusing on high insurance costs and bespoke code approvals, and argued that normalizing mass timber in regulatory and financial frameworks is the key to scaling. The eighth piece, arguably one that should have been much earlier in the series, explored the various technologies in mass timber and its currently dominant form, CLT. The ninth piece assessed the global leaders, opportunities and competition for Canada’s mass timber industry and considers lessons to learn. The tenth piece deals with input regarding labor and financing I received over the course of the series from professionals engaged in the space. The eleventh piece focused more on a speed and labor opportunities that mass timber construction has demonstrated. The twelfth turned to carbon accounting and international standards. The 13th article turned to the subject of end-of-life final resting places for mass timber, something introduced in the previous piece. The thirteenth piece turned to a question that was raised at various times in comments, the question of fire safety.

In Milwaukee the Ascent tower is a good starting point. At 25 stories and just under 87 meters tall it is the tallest mass timber building in the world today. It is a hybrid with a concrete podium and core but from the seventh floor up the frame and floors are glulam beams and CLT panels. Ascent houses nearly 260 apartments and has become a test case for American adoption of tall timber. The developer estimates it locked away over 7,000 tons of carbon while saving months on construction time. The building makes the case that timber high rises are no longer an experiment but a practical choice in major cities.

Norway’s Mjøstårnet set the tone in Europe when it opened in 2019. At 85 meters it briefly held the record for the tallest timber tower. What is more important is that it is an all timber structure aside from some concrete topping for acoustics. The glulam and CLT frame supports a hotel, apartments, offices, and restaurants. All of the wood was harvested locally and milled nearby, making it a showcase for Norway’s forest industries. It stands by a lake in a small town but its impact has been global. It proved to skeptics that tall wood buildings could be built safely and economically.

Vienna’s HoHo tower is another milestone. At 24 stories it uses about three quarters timber in its structure with concrete cores for stability. Prefabricated CLT and glulam components allowed the project to move quickly. The building houses offices, apartments, a hotel, and wellness facilities. HoHo has won awards for architecture and engineering and stands as a visible marker in Vienna’s skyline. The city accepted it as part of the urban fabric, which signals how mainstream timber construction has become in Europe.

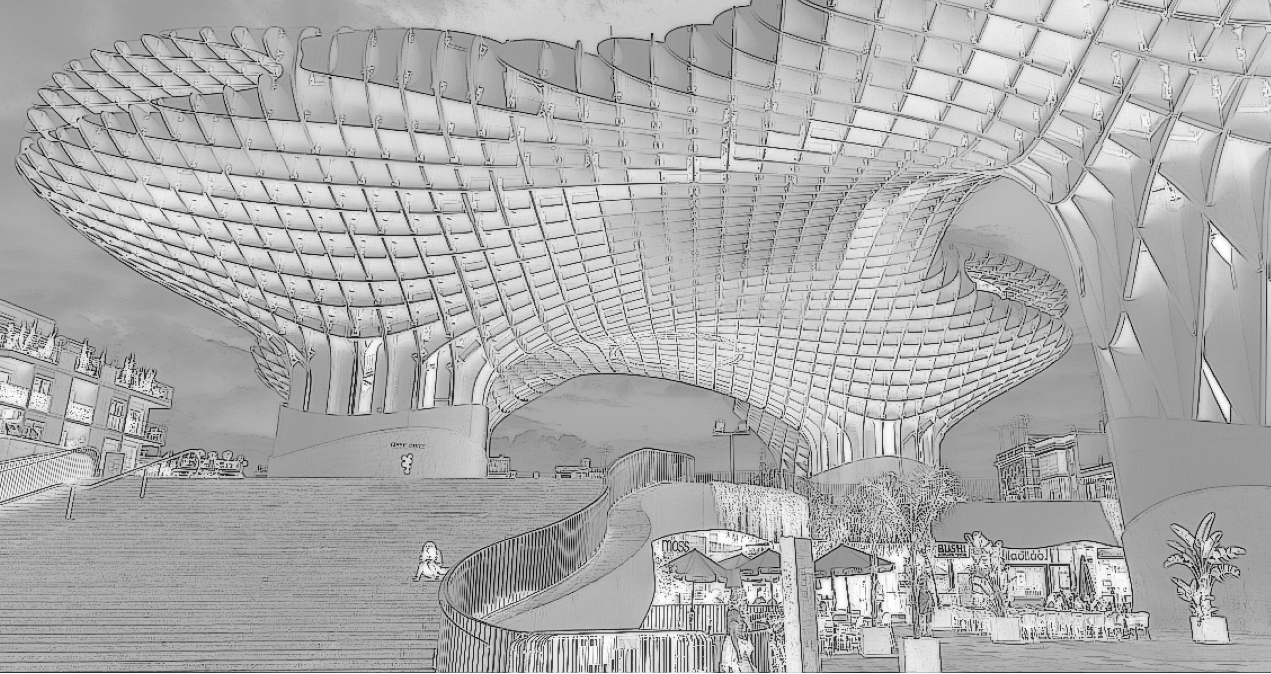

ChatGPT generated charcoal sketch of the interior of Sara Kulturhus in Skellefteå, Sweden, capturing its soaring timber structure and lively public space

ChatGPT generated charcoal sketch of the interior of Sara Kulturhus in Skellefteå, Sweden, capturing its soaring timber structure and lively public space

In Sweden the Sara Kulturhus is a cultural and civic landmark. The 20 story complex includes theaters, a museum, a library, and a hotel. It uses locally harvested timber in CLT modules braced by glulam beams. Its designers left much of the wood exposed to celebrate craftsmanship and connect the building to Sweden’s northern forests. It shows how timber can serve not only commercial functions but also civic pride and culture.

Australia has a project under construction that will take the height record if it completes on schedule. Atlassian Central in Sydney will be 40 stories and around 182 meters tall. It will use a steel and glass exoskeleton but inside the structure will be built from mass timber. The design calls for natural ventilation and planted terraces every few floors, targeting a 50 percent cut in embodied carbon compared to a standard tower. When it opens it will be both a headquarters for a global software firm and the tallest hybrid timber tower in the world.

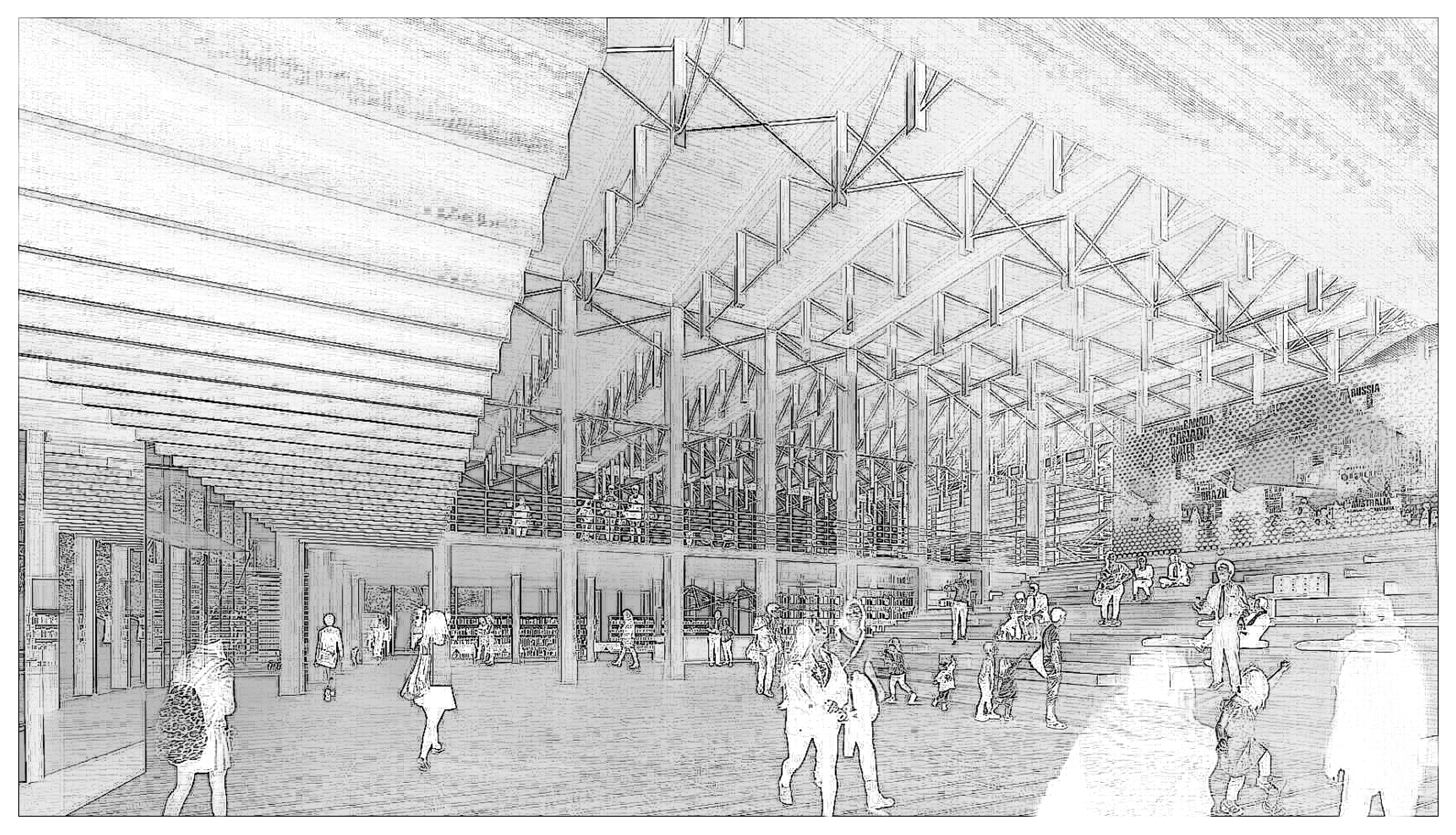

ChatGPT generated charcoal sketch of Rotterdam’s De Karel Doorman, emphasizing its modern façade rising above the bustling urban square

ChatGPT generated charcoal sketch of Rotterdam’s De Karel Doorman, emphasizing its modern façade rising above the bustling urban square

Not all interesting projects are new builds. Rotterdam’s De Karel Doorman showed how timber can extend the life of old structures. A 1950s concrete retail block was topped with a 16 story residential addition made of timber, steel, and glass. Using CLT floors and glulam posts kept the new weight light enough for the old foundations. This allowed the building to be reused and expanded rather than demolished. It is a powerful example of adaptive reuse with timber.

Melbourne’s 55 Southbank Boulevard did something similar. An eight story office block from the 1980s was given ten more stories in CLT, converted into a hotel, and rebranded as the Adina Apartment Hotel. The timber kept the additional structure light while adding over 200 rooms. The project avoided demolition waste and locked away thousands of tons of carbon, showing how vertical extensions in timber can refresh aging urban buildings.

In Madrid the Ombú project by Foster + Partners demonstrates how mass timber can bring new life into historic shells. A 1910 industrial brick building was preserved while its interior was rebuilt with a demountable CLT and glulam frame. The new wooden skeleton houses offices in a light filled, biophilic space while respecting the old masonry exterior. The retrofit saved over 1,600 tons of carbon and avoided the waste of demolition. It is both sustainable and heartwarming, giving a century old building a new role in a net zero future.

Timber is also moving into infrastructure. In 2012 TimberTower in Germany built a 100 meter wind turbine mast from glulam panels. It cut hundreds of tons of steel and CO₂ emissions compared to a conventional tower. In Sweden Modvion has gone further with laminated veneer lumber turbine towers that are modular for easier transport. Their 30 meter pilot proved the idea and they now have orders for 110 and 150 meter towers. Wooden turbine towers not only cut carbon but also store it, attacking climate change on two fronts.

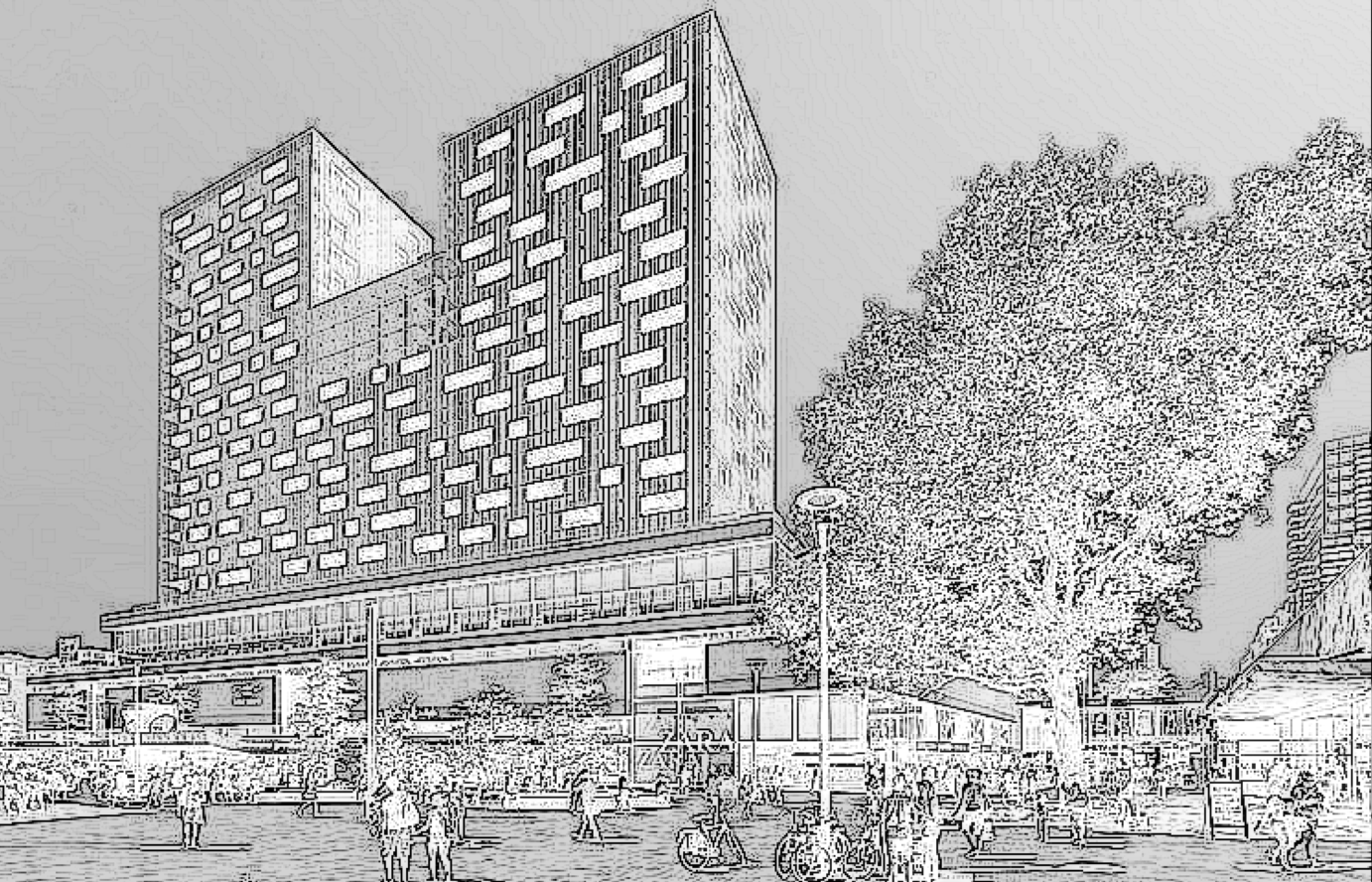

ChatGPT generated charcoal sketch of the Mistissini Bridge in Quebec, highlighting its timber arches and mirrored reflection in the water

ChatGPT generated charcoal sketch of the Mistissini Bridge in Quebec, highlighting its timber arches and mirrored reflection in the water

Canada has built one of the longest modern timber bridges. The Mistissini Bridge in Quebec spans 160 meters using glulam girders and CLT decking. It carries vehicles year round through harsh winters and has proven durable since 2014. It is also a project that supported Indigenous communities and local forestry, making it both technically impressive and socially meaningful.

Some projects push the envelope in more whimsical ways. In Seville the Metropol Parasol, known locally as Las Setas or the mushrooms, is the largest wooden structure in the world by area. Its six giant mushroom shaped canopies cover a public square with shade, markets, and a rooftop deck. Built from bonded laminated veneer lumber, the 150 by 70 meter structure is both sculpture and civic infrastructure. It turned a neglected square into a destination and became a beloved urban landmark.

In Zurich Shigeru Ban’s Tamedia headquarters showed another path. It is a seven story office where the timber frame is assembled without metal fasteners. Instead traditional joinery and wooden dowels hold the interlocking beams and columns together. The precision of modern milling allowed a design that recalls ancient temples but performs to Swiss codes. Inside, hundreds of workers operate in a glass walled office framed entirely by visible wood.

In the UK the Maggie’s Oldham cancer support center broke new ground by using hardwood CLT made from American tulipwood. The exposed panels have the grain and feel of fine furniture, creating a warm and comforting atmosphere for patients. It was the first permanent building in the world to use hardwood CLT and won awards for both innovation and humanity. The choice of wood was not just technical but emotional, connecting architecture with healing.

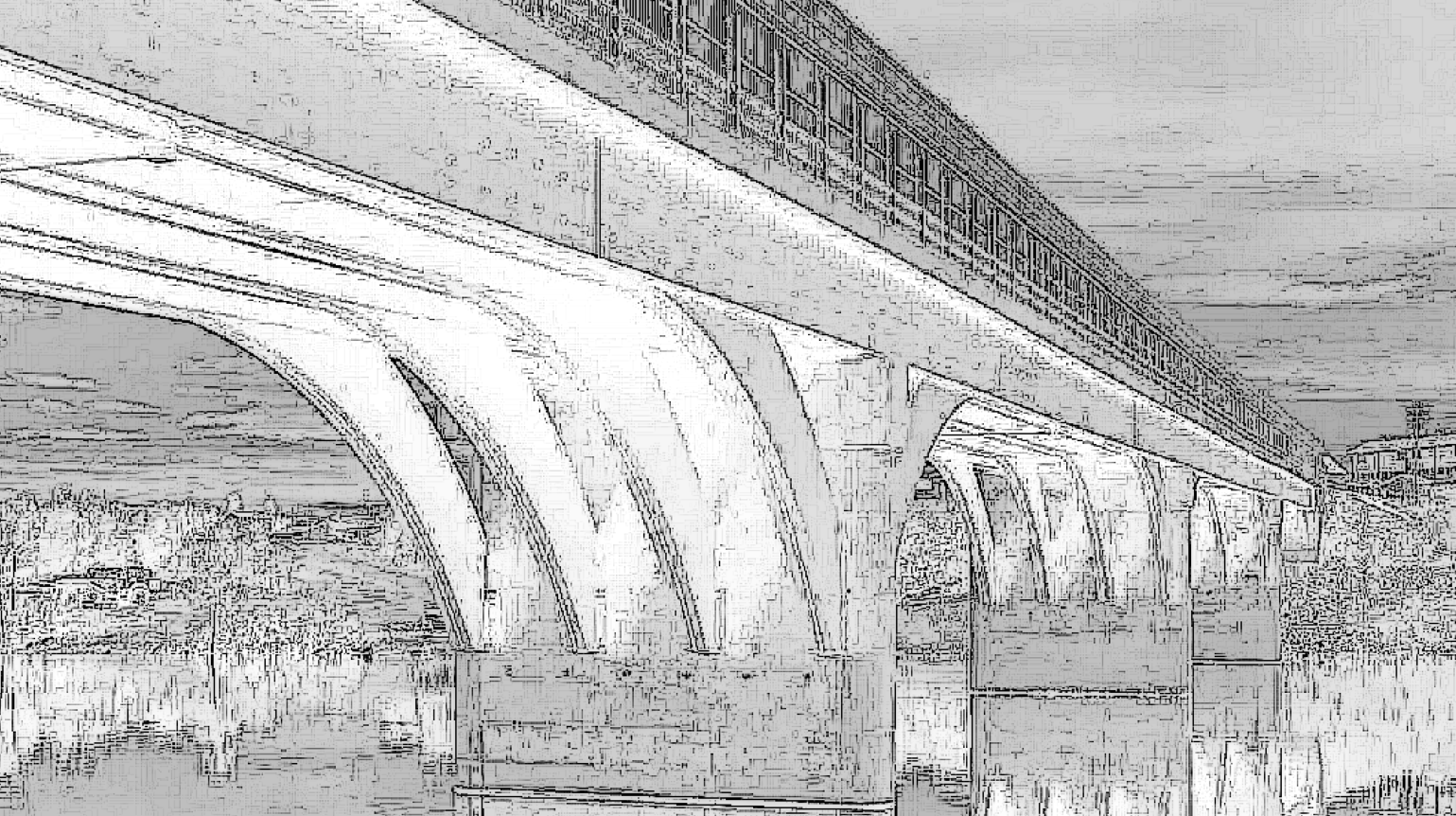

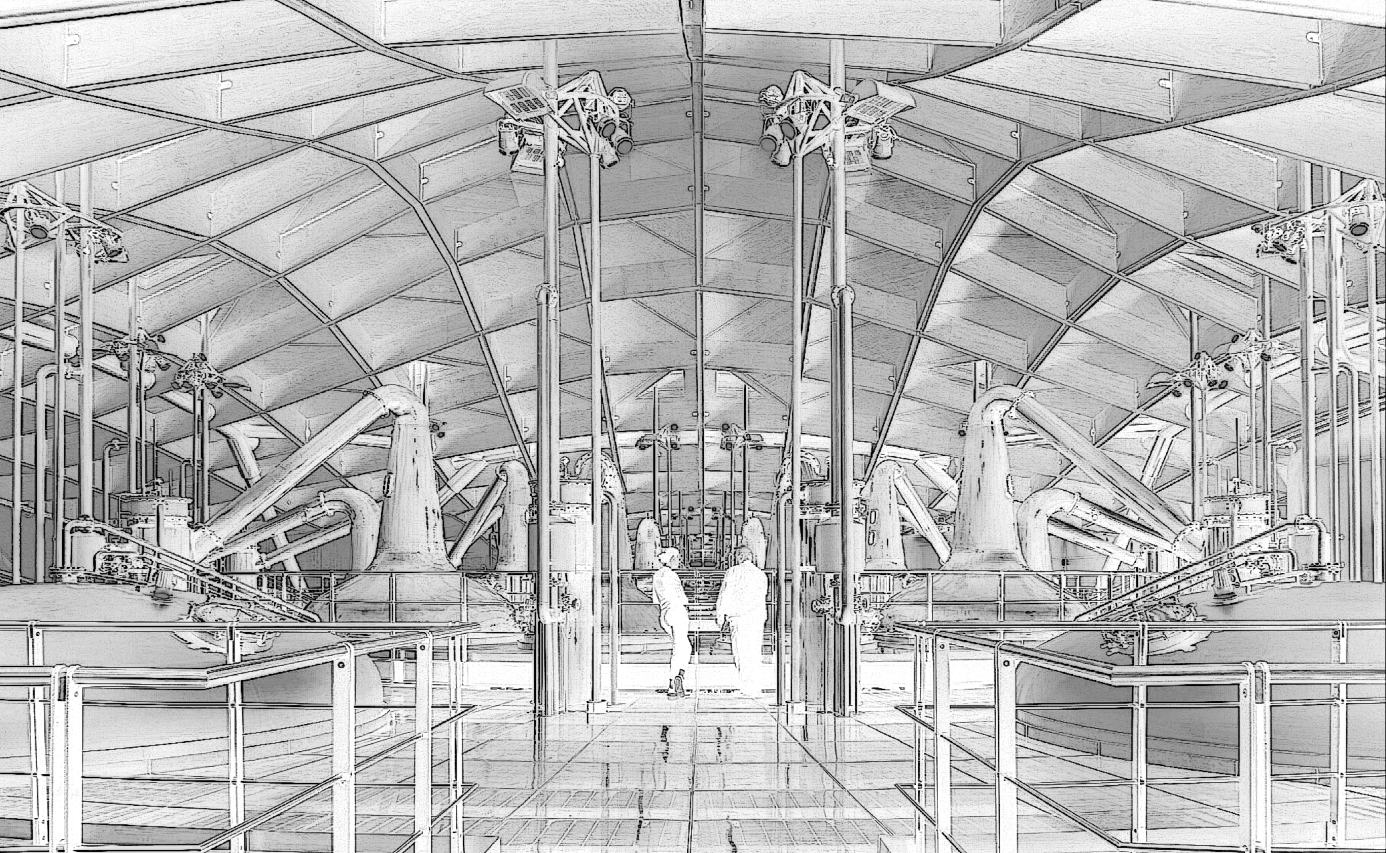

ChatGPT generated charcoal sketch of the Macallan Distillery in Scotland, showcasing its sweeping timber roof and iconic copper stills

ChatGPT generated charcoal sketch of the Macallan Distillery in Scotland, showcasing its sweeping timber roof and iconic copper stills

In Scotland the Macallan Distillery shows how timber can elevate industrial design. The facility is topped by an undulating roof of glulam beams and laminated veneer lumber panels, covered with grass so it blends into the hillside. Inside, the timber gridshell ceiling arches over copper stills in a dramatic display. The roof was prefabricated and assembled in only six months. It proves that timber can deliver both efficiency and beauty, even in industrial buildings.

Some of the most ambitious timber projects are still on the horizon. In Tokyo Sumitomo Forestry has announced plans for the W350 project, a 350 meter, 70 story timber skyscraper for 2041. It would use a braced tube frame with a nine to one wood to steel ratio, serving as a test bed for seismic resistant laminated wood. It is symbolic, marking the company’s 350th anniversary and envisioning a supertall where forests rather than concrete define the skyline.

In Zanzibar a project nicknamed Burj Zanzibar is planned as Africa’s first tall timber tower. At 28 stories and 96 meters it would contain nearly 270 apartments and community spaces. Its faceted pods will provide shading and natural ventilation, and its structure will be a hybrid of glulam columns and CLT floors. If it completes, it will be the tallest timber building on the continent and a statement that low carbon construction is possible anywhere, even in tropical climates.

Taken together these projects show the breadth of what is happening with mass timber. Some are breaking records for height, others are saving historic buildings, others are whimsical canopies or deeply human spaces. They cover homes, offices, hotels, cultural centers, bridges, and turbines. They are not just curiosities but working assets that reduce carbon, cut construction time, and often improve quality of life. Mass timber is proving to be one of the most adaptable tools we have for decarbonizing the built environment while reconnecting construction with one of humanity’s oldest materials.

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Advertisement

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.