A team of Japanese scientists explored how typical PV panel component materials affect the ability to re-use end-of-life PV cover glass. Specifically, they measured contamination by materials, such as aluminum, silicon, carbon, and copper, and their effects in melted PV panel glass cullet.

September 8, 2025

Valerie Thompson

Researchers at the Hokkaido Research Organization in Japan investigated the effects of residues of typical panel component materials in PV cover glass cullet when it is melted to be used in new products, such as sheet glass or glass for bottles.

The effects on component materials, such as aluminum and silicon, need to be better understood if end-of-life PV cover glass is to be recycled in higher-value applications, rather than used as filler or sand alternatives in construction.

The team focused on separating materials using thermal processes and hot knife methods, which are seen as suitable approaches to recover PV glass while minimizing contamination risks.

However, as the team noted, there is a need for more research. “PV glass recycling through melting has not been sufficiently investigated,” Hiroyuki Inano, corresponding author of the research, told pv magazine.

“We found that small amounts of contaminants from the PV panel affect the molten glass. The quality of the PV glass cullet decides the subsequent usage,” he stated.

In the experiments, the researchers studied the reactions between the PV panel glass and contaminants that could emerge during panel disassembly and subsequent melting, especially antimony oxide in PV glass and silicon contaminants.

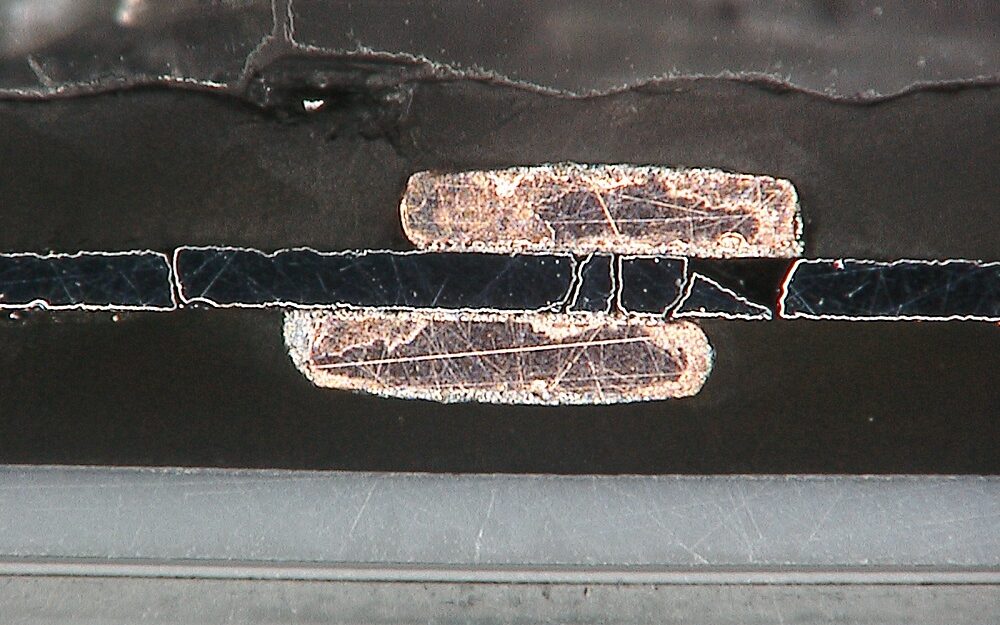

They used chemical reagents representing the components of a panel, specifically aluminum (Al) representing the frame, silicon (Si) representing the cells, copper (Cu) for interconnectors, tin (Sn) for solder, and carbon (C) for the ethylene vinyl acetate (EVA) resin.

The glass samples with each reagent were melted at elevated temperatures and evaluated using X-ray diffraction (XRD). “Additionally, redox reactions between glass-component oxides and these elements were investigated through chemical thermodynamics calculations,” they said.

The contaminants were found to color the glass. For example, Cu turned the glass blue. Si, as a contaminant at 0.01 mass%, did not affect the glass, but 0.1 mass% of Si turned the sample glass yellow.

With more Si added, antimony oxide was reduced, and excess Si remained, according to the research. “Si fine particles attached to the cullet cannot be removed easily. Si contamination in PV glass significantly influences the redox equilibrium, potentially affecting the color of the glass and altering its composition due to the reduction of oxides,” the group said.

It is now working on another melted glass study, this time testing materials originating from PV panels, rather than reagents.

The details of the study appeared in “Impact of silicon and other contaminants on the melting process in photovoltaic glass recycling,” published in Journal of Non-Crystalline Solids.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Popular content