There is nothing in watchmaking quite as fascinating as complications. They mark the point at which a watch stops being only a device for keeping time and becomes a testament to what the craft itself can accomplish. Though many complications were born of necessity, they endure because they show, more clearly than anything else, the heights mechanical ingenuity can reach when confronted with the constraints of miniature mechanics.

Complications are hence the proving ground of the craft, where effort and intellect are expended not so much to make the watch more useful in a world that no longer depends on it, but to meet challenges that exist only within the very specific boundaries of horology. The aim of one complication is never the same as another, nor are the obstacles. Each sets its own terms and requires its own internal logic. At times, an added condition sharpens the test. Slimness is a good example. To build a perpetual calendar is one challenge; to build one that is also ultra-thin adds a second layer of difficulty. This is what makes complications endlessly fascinating — the goals they set, the problems they seek to overcome, and ultimately, the paths chosen. Solutions flow from the nature of the problem, but they are always filtered through the imagination of the maker. It is in the act of invention under constraint, whether imposed by physics or chosen by ambition, that the art proves itself.

In our time, few companies have sought to advance complications as boldly as Audemars Piguet has. Its Research and Development series, RD#1 through RD#5, represents a decade-long inquiry into the most demanding mechanisms in watchmaking, each conceived as a response to a technical difficulty that the traditional form of the complication had left unresolved. What is most striking is that many of these solutions are directed toward making canonical complications genuinely practical for daily use.

Royal Oak Concept Supersonnerie (RD#1)

Ref. 26577TI.OO.D002CA.01

The series began in 2015 with the Royal Oak Concept Supersonnerie RD#1, a watch that combined a tourbillon, a chronograph and a minute repeater. It marked the debut of the Supersonnerie technology, developed over eight years of collaboration with the Ecole Polytechnique Fédérale de Lausanne (EPFL) and a host of other experts, including technicians, academics and musicians.

The RD#1 introduced Supersonnerie technology, achieving chimes of exceptional clarity and volume while providing water resistance

Beyond the complexity of converting the motion of the hands into the correct sequence of strikes, the most important aspect of any chiming watch is how it sounds. All things being equal, high volume and high quality in sound tend not to coexist, and there are many reasons for this.

A repeater generates its sound from very small components, namely slender steel gongs struck by tiny steel hammers, with the energy drawn from a dedicated mainspring. To make the sound louder, the gongs must vibrate with greater amplitude, and the case must act like a resonator that lets those vibrations escape. But in chasing volume, one risks losing control over the shape of the vibration. The note may become harsh, metallic or distorted, because the energy is spread too broadly rather than concentrated into a pure tone.

By contrast, to achieve a high-quality sound, one that is clear, sustained and with a pleasing timbre, the gongs and case must be tuned carefully. That usually means allowing the gongs to vibrate freely and cleanly, with resonance balanced over time rather than forced outward. Moreover, the case is often sealed for water resistance, which tends to suppress raw volume.

The material of the case also plays a central role. Carbon fiber or lightweight metals such as titanium amplify sound effectively and produce impressive volume, but they tend to lack refinement, giving a dry or brittle timbre. Rose gold, by contrast, is widely regarded as ideal for tonal quality. Its higher copper content stiffens the alloy, trimming its brightness and giving the sound a rounded character, while the density of gold ensures clarity and sustain. Together, they produce a resonance that is rich, balanced and warm, though at the expense of sheer volume. The solution introduced in the Royal Oak Concept Supersonnerie RD#1 was ingenious as it combined the best of both worlds. The case itself was made of titanium, ensuring volume, but the innovation lay in a resonance membrane — an inner caseback sandwiched between the outer caseback and the movement. Made of a copper alloy, the membrane was the surface to which the gongs were fixed rather than the mainplate. Instead of relying solely on the case to transmit vibration, the membrane acted as a soundboard, which amplified and shaped the sound before releasing it through small apertures in the titanium caseback.

The membrane was left free to vibrate, while the movement remained hermetically sealed. This allowed the caseback to be pierced without compromising dust or water resistance, with the apertures giving the amplified sound a direct path outward. This also enabled Audemars Piguet to tune the tonal qualities with far greater precision. The copper alloy enriched sustain and body, while the overall design preserved the clarity and projection that titanium provided. The result was a repeater that projected its sound with unusual strength, yet retained a level of refinement seldom found in loud repeaters.

Audemars Piguet also re-engineered the traditional anchor governor, whose regulation of the repeater train typically produces a noticeable clicking. Instead of abandoning the anchor for a fly governor, which is quieter but dependent on friction and prone to drift as lubricants age, they retained the anchor for its reliability but redesigned its pallet fork. In the new construction, each pallet is mounted on an elastic arm with a microscopic bend that allows it to flex when struck by the teeth of the escape wheel. The deflection absorbs energy and cushions the stop, so the wheel is arrested progressively rather than with a sharp impact. The result is a governor that retains the stability of the anchor while suppressing the extraneous sound that would otherwise accompany each release. The strike racks themselves were also reconfigured to eliminate the silent interval traditionally heard between hours and minutes when no quarters are struck.

Supersonnerie technology eventually made its way into regular-production Royal Oak Minute Repeater models, and later into Code 11.59 by Audemars Piguet Minute Repeaters as well as Grande Sonneries, setting new acoustic standards for chiming watches.

Royal Oak Selfwinding Perpetual Calendar Ultra-Thin (RD#2) Ref. 26586IP.OO.1240IP.01

Of all the watches in the RD series, the Royal Oak Selfwinding Perpetual Calendar Ultra-Thin RD#2 is perhaps the most well-known. With a case of just 6.33mm thick, it was, at its debut in 2018, the thinnest perpetual calendar ever made. The technical solutions it put forth remain both memorable and highly compelling, chiefly because they were as elegant as they were radical, and stand among the most striking demonstrations of what the RD program set out to prove.

Measuring just 6.33mm thick, the RD#2 has a traditional dial layout that belies a masterclass in gear design

In a traditional perpetual calendar, the 48-month program wheel is not a gear at all but a cam. Its perimeter is cut with notches and raised sections of varying depths, each one corresponding to the length of a particular month. Because it cannot transmit motion on its own, watchmakers add a separate 48-month toothed wheel, along with an intermediary train, to drive the month hand. In the RD#2, Audemars Piguet collapsed these roles into a single component. The program wheel here is both cam and gear, governing the grand lever with its profile, while simultaneously driving the month pinion directly.

The date wheel, on the other hand, is traditionally a 31-point star. It carries a finger to advance the 48-month toothed wheel at the end of each month. it is also rigidly fixed to an end-of-month snail cam, which is read by a feeler on the grand lever to trigger the correction for f months shorter than 31 days. This results in three stacked layers.

Audemars Piguet Royal Oak Selfwinding Perpetual Calendar Ultra-Thin (RD#2)

In the RD#2, the date star has a single asymmetrical tooth adjacent to a notch, which allows it to be directly engaged by a pawl on the grand lever for multi-step advancement at the end of months with fewer than 31 days. One of the standard teeth also projects radially beyond the others, acting as a finger that advances the month wheel once per full revolution. This design replaces both the end-of-month snail cam and the separate finger, effectively reducing three layers to one.

These solutions also allowed the grand lever to be a flat, planar piece that lies in the same plane as the date and month wheels. Its two-finger pawl is a single flat piece with an integral return spring, mounted on a flat cylindrical articulation. The lever’s curved feeler tail is concentric with its pivot. This coplanar construction keeps the thickness essentially at that of a single wheel. In many classical perpetuals, the lever work is stepped across levels to access the different layers.

The result is a movement just 2.89mm thick, compared with the 3.95mm of the Caliber 2120/2800, which employs a traditional 12-month cam with a Maltese cross satellite, or the 4.31mm of the Caliber 5134, which integrates a coplanar leap-year cam. These solutions were too good to remain confined to a single scenario. After the production version launched in 2019, they were adapted across wholly different movements, including the revolutionary Caliber 1000 in the RD#4 and the landmark Caliber 7138.

The date wheel and month wheel are capable of indexing and meshing respectively while simultaneoously interacting directly with the grand lever

Royal Oak Selfwinding Flying Tourbillon Extra-Thin (RD#3) Ref. 26660ST.OO.1356ST.02

The RD#3 was launched in 2022 to mark the 50th anniversary of the Royal Oak. It was remarkable in that the original iteration retained the hallowed dimensions of the Jumbo — 39mm by 8.1mm — but managed to integrate a flying tourbillon. A regular-production version followed later the same year, featuring the same ultra-thin flying tourbillon in a 37mm case.

In 2022, the RD#3 was released in a compact 37mm steel case with a purple dial

Caliber 2968 is a full-rotor selfwinding automatic movement measuring 29.6mm across and just 3.4mm high, only marginally thicker than the 3.2mm Caliber 7121 introduced the same year. It adopts many of the same architectural strategies, such as offsetting the center wheel to maximize the barrel size and reduce overall thickness. The barrel, in turn, drives the minute pinion directly.

Caliber 2968 in the RD#3 features a peripherally driven tourbillon cage made of titanium

The main event is the construction of the tourbillon, balance and escapement. The tourbillon cage integrates a toothed wheel that enables it to be driven on its periphery by the finishing wheel in the going train rather than via a pinion beneath the cage. This arrangement eliminates vertical overlap, contributing to a thinner architecture.

The tourbillon cage is crafted from titanium to reduce inertia, allowing more of the available energy to reach the balance. The pillars of the tourbillon cage are cut away to create additional clearance for the balance rim, enabling Audemars Piguet to fit a larger balance. All things equal, a larger, high-inertia balance wheel offers greater stability of motion, helping it withstand the shocks a sportier watch is likely to encounter. Also notable is the balance wheel itself. It is free sprung, with six recessed regulating weights set into the rim, leaving the outer edge smooth to minimize air resistance during oscillation. At high amplitudes, this reduction in turbulence improves both efficiency and consistency. Because the weights sit within the rim rather than projecting outward, the rim can extend further, increasing its diameter and, with it, inertia.

The tourbillon lever escapement has also been optimized to allow the balance to reach amplitudes beyond 360 degrees without overbanking. The design is one of long action, with the fork sweeping a larger arc than in a conventional lever. To achieve this, the distance between the pallet fork pivot and the balance roller is increased, while the geometry of the horns, guard pin and safety notch is reworked. As a result, the escapement absorbs extreme amplitudes without jamming, improves shock recovery and isochronism, and provides headroom for higher driving torque, all while retaining the proven reliability of the guard-pin safety system.

Code 11.59 by Audemars Piguet Ultra-Complication Universelle (RD#4) Ref. 26398BC.OO.D002CR.02

The Code 11.59 by Audemars Piguet Ultra-Complication Universelle RD#4, launched in 2023, was, in a word, revolutionary. It is a masterclass in reconciling complexity with user experience, distilling 23 complications into a watch that can be operated with intuitive ease.

The grande complication timepiece has long been a kind of white elephant in horology — enormous, unwieldy, forbiddingly complex and so fragile that every attempt to use it risked catastrophe. These were timepieces that demanded their instruction manuals be studied, and too often, their owners discovered that a single misstep meant a journey back to Switzerland.

In the RD#4, labeled pushers put every function at hand, turning the grande complication from forbidding to accessible

The RD#4 dramatically altered this paradigm. It demonstrated that a grande complication could be compact, robust, coherent in design and intuitive to use, while encompassing the full suite of traditional high complications and more. Measuring 42mm in diameter and only 15.55mm in height (including its hinged back), it contains a perpetual calendar accurate until the year 2400, a grande and petite sonnerie with minute repeater , a split-seconds flyback chronograph and a flying tourbillon, all integrated into a selfwinding caliber composed of 1,100.

An exploded view of the RD#4, a grande complication that proved complexity could be compact, intuitive and more than the sum of its parts

Caliber 1000 was the product of seven years of development and represents the consolidation of earlier RD models. It reconsiders how complications are arranged, controlled and worn, while advancing the execution of each one. The perpetual calendar exemplifies this shift. Rather than encoding a conventional four-year leap-year cycle, it incorporates a centurial cycle, automatically accounting for non-leap years that occur at the end of each century. It will remain accurate without correction until the year 2400. Mechanically, this is achieved through a 36 month program wheel, rather than the usual 48, meaning February is always cut to 28 days. Leap years are not encoded in this wheel directly. A separate leap-year cam intervenes, limiting the drop of the grand lever into the February notch so that the month runs to 29 days every four years. Once every century, however, the combined action of the tens and hundreds cams pivots an additional lever to block this correction, ensuring that century years not divisible by 400 are treated as common years. This architecture allows for a more compact system with a year display driven directly off the secular gear train.

Additionally, to reduce height, the mechanism, like that in the RD#2, consolidates multiple layers into one. The end-of-month cam is integrated into the date wheel, and the month cam into the month wheel. Thus, both the program wheel and the date wheel serve as both gear and cam.

The moonphase display is equally ingenious — compact yet hyper realistic. The difficulty with conventional moonphase displays is that they never really resemble the Moon as it appears in the sky, however precise they may be. The dividing line between light and shadow — the terminator — is not a fixed curve. At the first crescent it is tightly bowed, straightens at the half Moon, and bends the other way. A traditional display, with its static convex aperture, cannot reproduce these shifts.

In the RD#4, two concentric disks with six printed positions each generate 10 transitional stages in the lunar cycle. Together, they reproduce the age of the Moon with greater fidelity — a display that is not only compact but visually closer to the astronomical phenomenon it depicts. Adjustment is equally advanced. The Moon and day are set by caseband pushers, while the date and month can be adjusted bi-directionally via the crowns without risk of damage.

The sonnerie is no less significant. A grande sonnerie, which strikes the hours and quarters in passing, is the most complex of all complications, adding three distinct mechanisms to the basic minute repeater: an automatic release for the sonnerie, a manual release for the repeater and a silencer. Additionally, the strike racks were redesigned to eliminate dead time traditionally heard between hours and minutes when no quarters are struck, producing a consistent cadence. The minute repeater, meanwhile, is actuated by a pusher rather than a slide, contributing to both water resistance and ease of use.

It also employs Supersonnerie technology with gongs mounted on a resonating soundboard between the caseback and the movement. The soundboard here is a sapphire crystal, only 0.6mm thick, which both amplifies the vibrations of the gongs and reveals the movement beneath. A hinged gold outer back with apertures enables sound to be projected when worn on the wrist, while maintaining water resistance of 20m.

At 6 o’clock is a flying tourbillon with a free-sprung balance beating at 3Hz. The geometry, first developed for RD#3, extends the distance between the balance and pallet fork pivots, allowing very high amplitudes without overbanking and enabling greater torque in the barrels. In contrast to RD#3, which employed a flat hairspring for thinness, RD#4 reinstates an overcoil to optimize isochronism.

The chronograph demonstrates yet another innovation. The lateral-clutch, flyback chronograph incorporates a split-seconds mechanism, but unlike traditional rattrapantes, the split assembly is housed within the hub of the automatic rotor. The split wheel, clamps and column wheel are arranged inside the oversized ball-bearing housing, saving height and leaving the chronograph mechanism, visible.

All functions are accessible through labeled crowns and pushers without the need for a stylus. On the left are pushers for repeater, day and moonphase; on the right, three crowns with co-axial pushers for chiming mode, date, chronograph and month. The result is a level of operational clarity unprecedented for a watch of such complexity. It has fundamentally changed the way we view complications — proving that complexity need not exist for its own sake. RD#4 went on to win the prestigious Aiguille d’Or at the Grand Prix d’Horlogerie de Genève in 2023, and well-deserved recognition as as the best overall timepiece in 2023.

Royal Oak “Jumbo” Extra-Thin Selfwinding Flying Tourbillon Chronograph (RD#5)

Ref. 26545XT.OO.1240XT.01

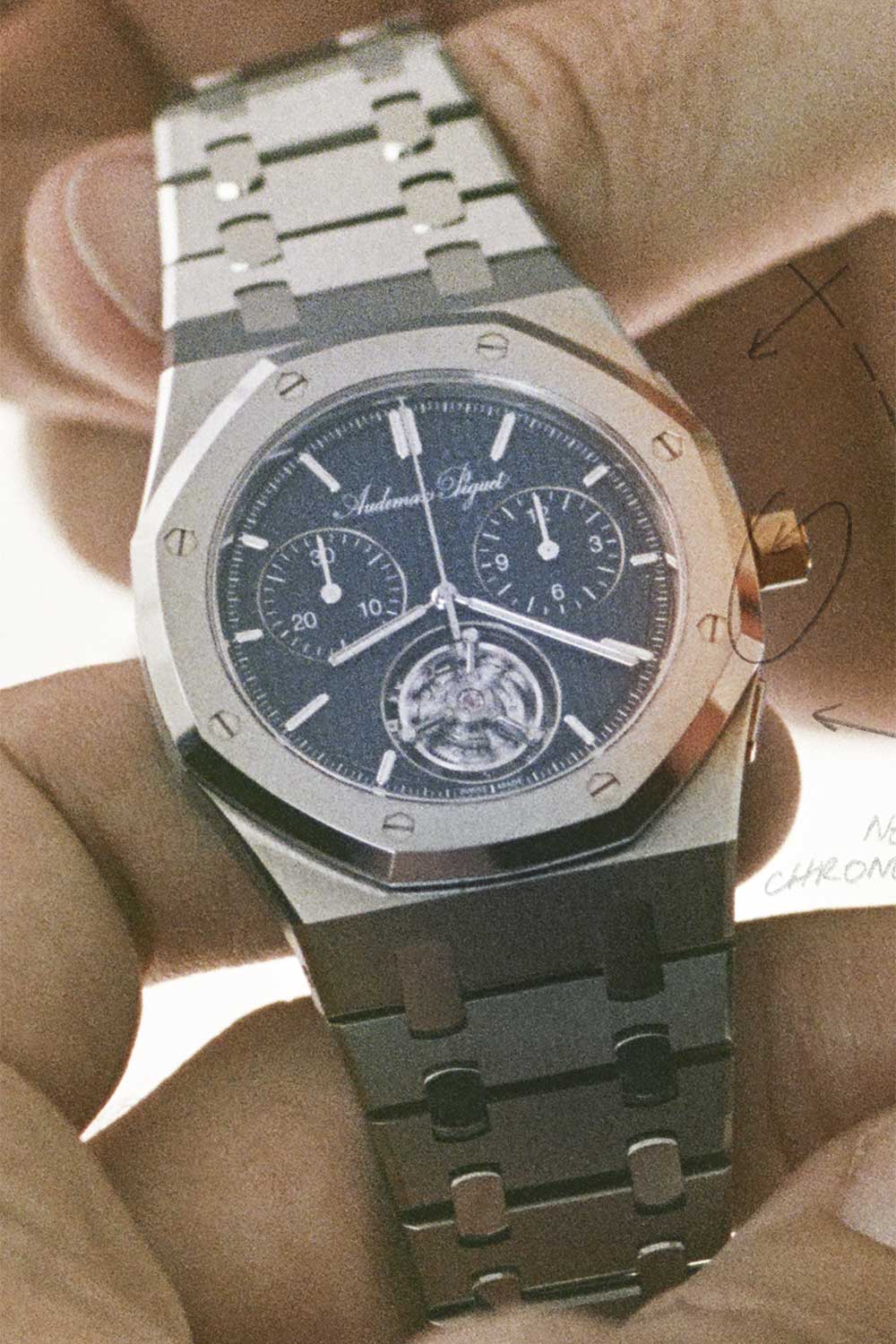

The latest in the series, unveiled for Audemars Piguet’s 150th anniversary, takes on one of the most celebrated yet technically demanding complications in watchmaking — the chronograph. Five years in development, the Royal Oak “Jumbo” Extra-Thin Selfwinding Flying Tourbillon Chronograph RD#5 introduces an entirely new movement, the Caliber 8100, which unites a flyback chronograph with a flying tourbillon.

The RD#5 comes in a titanium and BMG case that preserves the dimensions of the Jumbo, standing just 8.1mm high

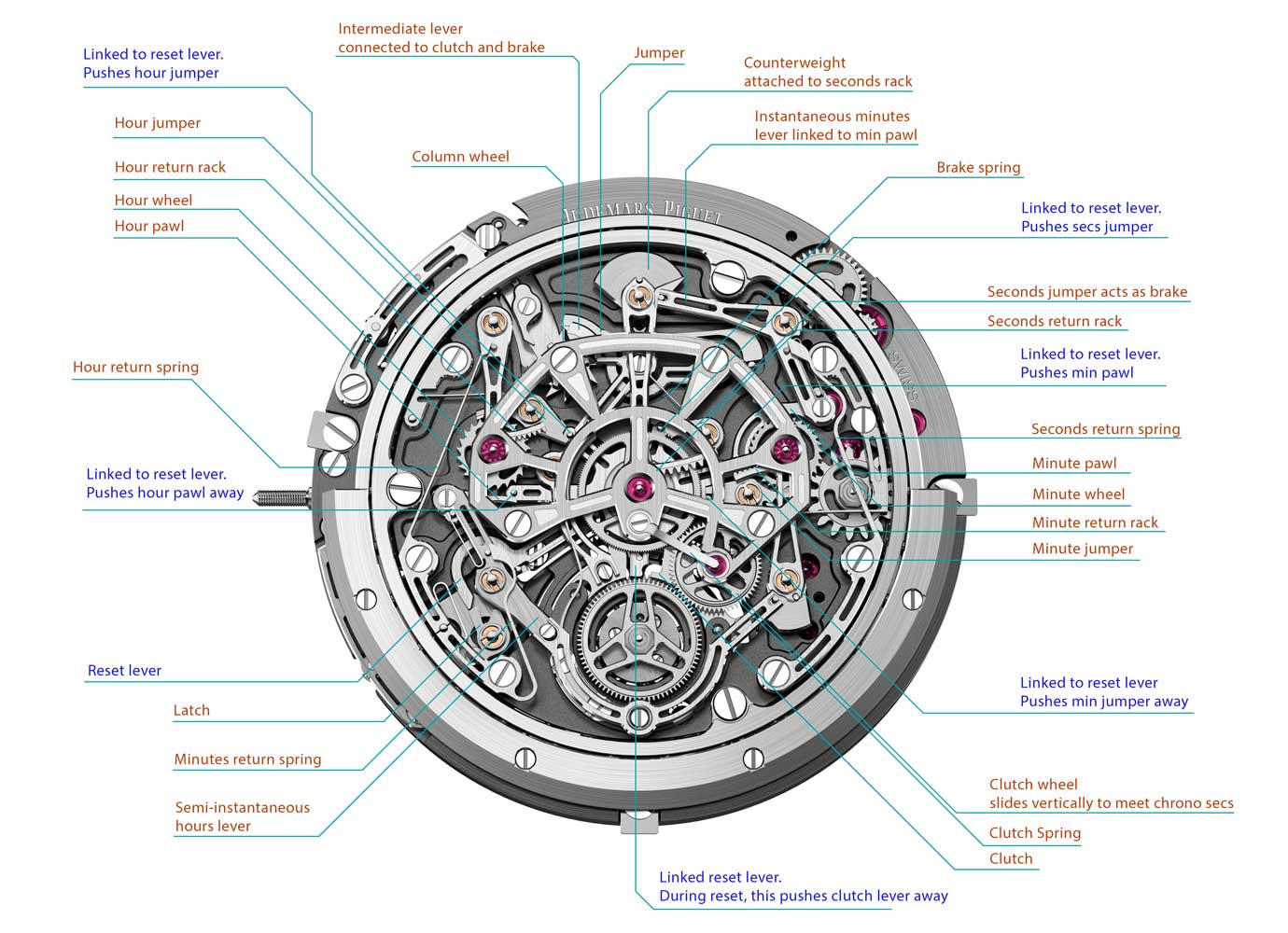

Impressively, the case once again retains the original dimensions of the Jumbo — 39mm × 8.1mm. The case middle is crafted in titanium, while the bezel, push-pieces, crown function-selector and studs are made of Bulk Metallic Glass (BMG) — an amphorus palladium allow first introduced in the one-off Royal Oak “Jumbo” Extra-Thin made for Only Watch 202. BMG offers exceptional scratch resistance and toughness, making it ideal for a high-performance chronograph The chronograph mechanism is astonishing, to put it mildly, and a reminder of how often we declare a subject exhausted, only to discover that it was merely waiting for someone to look at it differently, and in this case, very differently. Instead of the customary hammers and heart cams, the return-to-zero action is managed by racks and pinions. The rack, also provides a clean way to generate an indexing impulse for an instantaneously jumping minutes. Yet, viewed in isolation, both are executed in the most complex and unconventional way ever seen in a chronograph. The question is why?

The answer lies in the pursuit of a different kind of chronograph, one in which the very architecture of the control system is re-engineered to give the pushers a softer feel. In a traditional chronograph, the stiffness of the pushers comes from the way the system is organized around the column wheel. When the start or stop button is pressed, the operating lever drives the column wheel forward by one step. Each advance requires the jumper spring to be lifted clear of a ratchet tooth before snapping back into the next tooth, creating a sharp, resistant feel. At the same time, the rotation of the column wheel must lift certain levers, each held in position by its own spring. The pressure applied to the column wheel must overcome these forces indirectly to lift them. In a flyback, the load is reduced as the reset lever does not go through the column wheel. Additionally, the operating lever is often long, spanning from the pusher to the column wheel. When the button is pressed, the pusher drives this long lever, which then rotates the column wheel via a click held in tension by a spring. The length introduces elastic play, absorbing energy before any movement occurs.

The latest in the series, the RD#5 reimagines the chronograph to deliver pushers as light to the touch as those of a smartphone

The reset pusher is even stiffer, because the connection is more direct. Pressing the button cocks the hammer spring, which must be strong enough to drive the reset hammers firmly onto the heart cams mounted on the chronograph wheels. The cams can be at any orientation when reset is triggered, so the spring must deliver enough energy to snap each wheel back to its zero position in one clean motion, no matter how many counters are in play. Thus, the reset button in a conventional chronograph is almost always the heaviest to operate.

The short-travel, low-force pushers of the RD#5 deliver a smoothness likened to tapping a smartphone, achieved through a wholesale revamp of the chronograph mechanism

In the RD#5, the pusher is positioned close to the column wheel so the operating lever is short and rigid, requiring less force. Notably, instead of directly moving the brake or the clutch levers, the column wheel only acts on an articulated intermediate control lever. This lever is connected to the clutch lever. When the column wheel rotates and releases it, the lever pivots and allows the clutch spring to push the clutch wheel into engagement. The user feels only the resistance of the column wheel jumper spring, which still gives a crisp click, while the load of the clutch spring is taken up within the mechanism. In other words, indexing and actuation are separated. The finger supplies just enough force to advance the column wheel, while stored spring energy performs the actual engagement and disengagement of the clutch.

At the same time, a secondary finger formed on the intermediate lever coordinates the seconds jumper. In stop mode, it presses the jumper into locking engagement with the chronograph seconds wheel, and in start mode, it withdraws to release it. This ensures that the locking and unlocking of the chronograph seconds wheel is perfectly synchronized with the engagement and disengagement of the clutch, without any extra effort required at the column wheel.

Similarly, the lack of heart cams and reset hammers is meant to reduce the load on the reset pusher. The three chronograph wheels for the seconds, minutes and hours are each attached to a pinion with a sector of functional teeth. These pinions mesh with their respective racks, which are gradually charged as the wheels turn. At the moment of reset, this stored energy is released to drive the counters back to zero. The reset pusher does not supply the energy to move the hands; it only actuates a reset lever, which has six arms that can simultaneously push or lift all the jumpers and pawls locking the chronograph wheels. Once freed, the racks snap back under their own springs, dragging the counters cleanly to zero.

Components of Calibre 8100 in the RD#5, with the six-armed reset lever visible near the center

As this is a flyback, the reset lever is not governed by the column wheel but engaged directly by pressing the pusher. This separation reduces the force required at each pusher. The reset lever has a dedicated arm that disengages the clutch lever at the precise instant its other arms release the jumpers and pawls. The chronograph seconds, and by extension, the minutes and hours wheels are uncoupled and freed, each returning to zero under the force of its rack and spring. As soon as the reset pusher is released, the reset lever springs back to its rest position, the clutch re-engages, and the chronograph resumes its run seamlessly. To reduce intertia, various chronograph components are made in titanium, such as the chronograph seconds hand and the chronograph wheel.

The effect for the user should be quite remarkable. Instead of the blunt, spring-loaded crash of a conventional reset lever, the action should be smooth, brief and light. The pusher stroke is extremely short — on the order of 0.3mm — and requires only a fraction of the force of a standard chronograph, closer to that of a smartphone button than to the heavy mechanical feel we have grown accustomed to. This is a watch that begs to be experienced in person. Images simply capture the complexity of the design, and it is only in use that the ingenuity of the mechanism will become fully apparent.

Notably, the chronograph also has an instantaneously jumping minutes. As the chronograph seconds wheel completes one revolution, its truncated pinion drives the teeth of the rack forward until the cutaway portion comes around. At that instant, the pinion and rack disengage, and the return rack snaps back to its initial position under spring force, with a counterweight ensuring balance. That retrograde movement is harnessed by a transmission lever carrying a pawl, which indexes the minute wheel forward by one step.

Like the spring of the seconds rack, the minute rack spring does not act on the minute rack directly, but on the transmission lever, which only swings through a few degrees for each minute jump. This design ensures the spring load remains nearly constant, whether fully charged or released, resulting in a consistent torque and a crisp, instantaneous minute jump every 60 seconds.

Every 60 minutes, the same principle applies to the hour wheel. During retrograde return of the minute rack, a transmission lever carrying the hour pawl advances the hour wheel. However, the hour rack is acted on directly by its spring, so its torque varies more widely. As the minute cycle nears its end, the hour pawl starts to engage he hour wheel progressively, and finally, the hour jumper locks it into the next index, making it semi-instantaneous.

The clutch is unlike the familiar horizontal or vertical systems, though it borrows from both. The clutch wheel is mounted on a shaft that slides axially between two positions. On one side, it meshes permanently with the drive wheel of the movement; on the other, it can be shifted into or out of mesh with the chronograph seconds wheel. When the chronograph is activated, the intermediate control lever pivots, releasing the clutch lever. Freed from restraint, the shaft and clutch wheel are pushed laterally by the clutch spring into their engaged position where the wheel meshes with the chronograph seconds wheel.

The automatic and manual winding trains, hand-setting train and gear train are all located on the dial side of the movement, enabling it to achieve an ultra-thin profile

This allows the clutch to retain the visual elegance of a horizontal coupling while engaging as smoothly as a vertical one, free from clash, drag or kickback. The drive wheel is part of the tourbillon cage, meaning the chronograph is driven off the cage. The flying tourbillon, identical to that in RD#3, is made of titanium and driven on its periphery by the last wheel in the gear train to reduce thickness. It houses an escapement optimized for long action as well as free-sprung balance with recessed weights.

What’s notable is the fundamental design of the movement. The manual and automatic winding trains, setting train and the gear train are all located on the dial side, freeing the bridge side to be almost entirely dedicated to the chronograph. This is made possible by a peripheral winding mass. Instead of a centrally mounted rotor stacked on top of the movement, the mass runs on ball bearings around the circumference, with the chronograph mechanism lying flush within its track. One of the thickest components of a conventional automatic caliber is thus eliminated, allowing the automatic train to be relocated without adding vertical bulk.

The function selector relies on two stacked star wheels to govern the switch between winding and setting. Actuated by a push-piece integrated into the crown, it toggles between the two modes, while the reverser isolates the trains so that only the selected one is engaged. This arrangement allows both winding and setting trains to be located on the same side of the movement, eliminating the need for a conventional sliding pinion. The barrel itself is unusual. It is not only a hanging barrel that is solely supported at its base but goes further in its construction to reduce thickness. The ratchet wheel itself encloses the mainspring without the need for a barrel cover. The barrel is no longer a closed drum but reduced to a cylindrical wall with peripheral teeth, lacking both base and cover to suppress height.

Iconic on the outside yet revolutionary on the inside, a fitting 150th anniversary commemorative edition complete with a special signature inspired by the brand’s historical logo

All these solutions are compelling, but what lingers is the sheer effort invested in reimagining the chronograph for the sake of creating softer pushers. It is exactly this kind of contrarian ambition that defines the RD series, which after 10 years, concludes with the RD#5: to take what was thought finished, and, with great patience, care and ingenuity, refine it and show that it could be otherwise. It is a reminder that progress in watchmaking rarely comes from adding more but from rethinking what already exists, and at its best, from enhancing the experience of use and with it, ownership itself.