Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

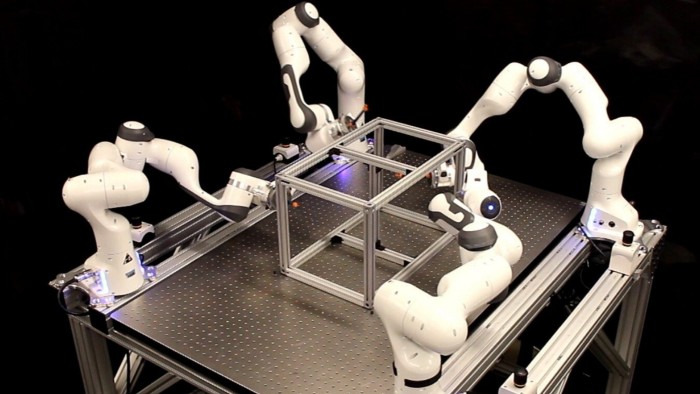

Scientists have used artificial intelligence to choreograph teams of robots to work together without colliding, an advance that promises to boost the efficiency of carmaking and other complex production lines.

The system, known as RoboBallet, potentially allows machine troupes to plan their work faster and complete more tasks, according to research from UCL and Alphabet’s subsidiaries Google DeepMind and Intrinsic.

The project shows how AI is driving efforts for industrial process optimisation, as developers seek to solve long-standing problems of robot team members getting in each other’s way.

“RoboBallet transforms industrial robotics into a choreographed dance, where each arm moves with precision, purpose, and awareness of its teammates,” said Matthew Lai, a researcher at UCL Computer Science and Google DeepMind. “It’s not just about avoiding crashes; it’s about achieving harmony at scale.”

The development of RoboBallet, which was funded by DeepMind and Intrinsic, is described in a paper published in Science Robotics on Wednesday.

The researchers found the best outcomes came from using a robot brain fed with data in graphical form that represented different potential scenarios involving a group of robot arms. The brain used reinforcement learning, in which it was guided to improve by receiving “rewards” — signals that it had finished tasks or done them faster than previously.

RoboBallet planned and executed 40 tasks involving eight automated arms compared with typical existing techniques, which used five robots for 10 tasks, Lai said. RoboBallet could make plans for new workflows in seconds whereas existing systems might take days, he added.

It could be well suited to car production lines where groups of robots were used to weld on parts, Lai suggested. “It’s really the scale and how fast we can do it that makes it special,” he said.

Another advantage of the system is that the robots learnt general principles of co-ordination, rather than memorising specific scenarios, the researchers said. This should give them the adaptability needed for large-scale industrial use where, for example, car bodies might arrive in slightly different positions.

RoboBallet was an “AI milestone” and a “critical step towards bringing a truly adaptive, hyper-efficient, planning technology to robotics and manufacturing at large”, said Torsten Kroeger, Intrinsic’s chief science officer.

The research highlights how AI advances are transforming the way robots move and navigate, allowing them to be taught faster, take on more sophisticated jobs and adjust better to changes in their environments.

Experts hope growing training databases comprising footage of robot actions will keep improving the quality of the machines’ output, just as large language models learn from archives of text.

RoboBallet has yet to be deployed on a real-life production line. Its limitations included that it can’t yet deal with robots with differing capabilities or tasks that have to be carried out in specific order, the researchers said. But the system should have the scope to take in these enhancements later, they added.

RoboBallet’s approach wasn’t “technically surprising”, but did seem to offer faster computation than some existing methods, said Russ Tedrake, a professor at the Massachusetts Institute of Technology and vice-president of robotics research at the Toyota Research Institute. The system’s development was part of a wider push that was developing better solutions for robot motion planning difficulties, he said.

“I do think it’s an important problem space and that [RoboBallet] could be very useful if it works well,” Tedrake said.

Video: Agentic AI – how bots came for our workflows and drudgery | FT Working It