IN A NUTSHELL

🌊 Oceans hold 150 times more carbon dioxide than the atmosphere, causing acidification and threatening marine ecosystems.

🔬 Direct Ocean Capture (DOC) uses electrochemical processes to remove CO2, converting it into biodegradable plastics.

🧫 Engineered microbes metabolize formic acid, producing succinic acid, a precursor for sustainable plastic production.

💡 DOC technology could revolutionize industrial practices by providing a sustainable source of essential chemicals.

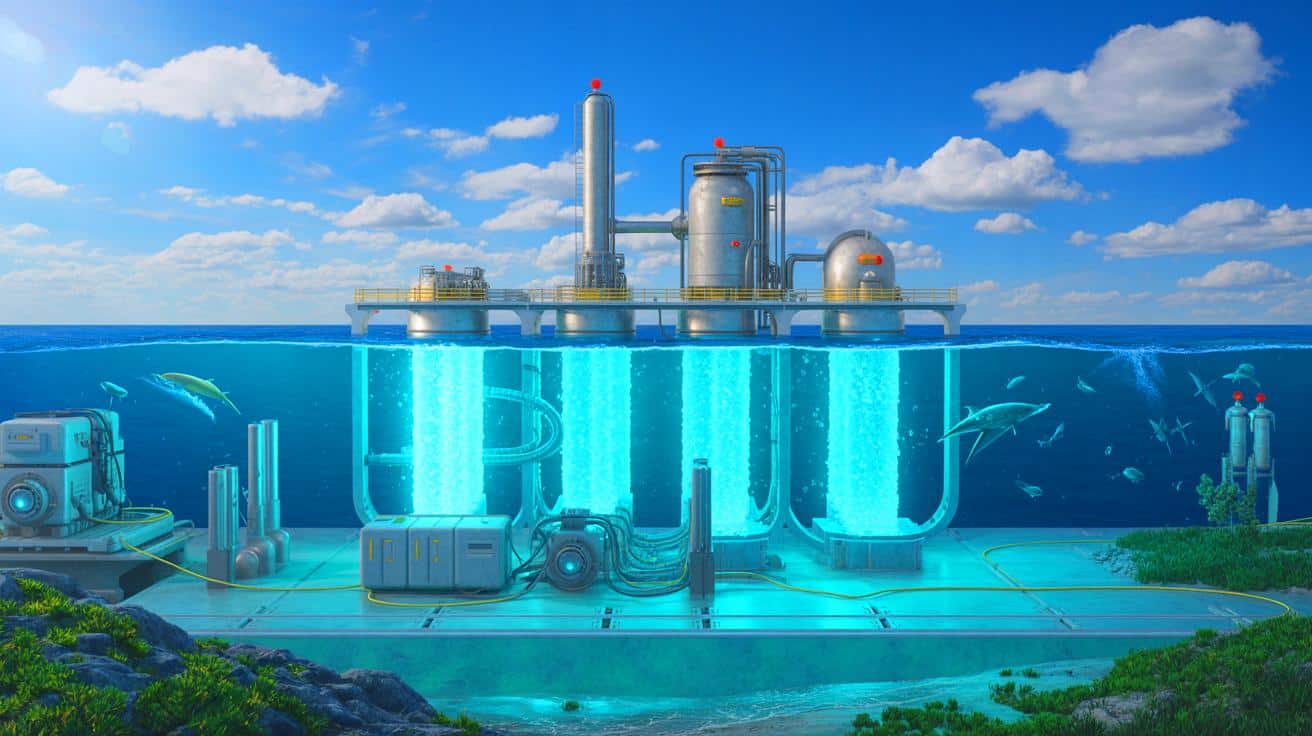

The Earth’s oceans are an immense reservoir of carbon dioxide, holding 150 times more CO2 than the atmosphere. This massive storage is both a challenge and an opportunity. Increasing levels of carbon dioxide in the oceans lead to acidification, which can negatively impact marine life and biodiversity. However, innovative methods are being developed to harness this stored carbon dioxide for beneficial uses, including the production of industrial chemicals for plastics. A new approach, known as Direct Ocean Capture (DOC), could potentially transform this environmental challenge into an opportunity by converting captured CO2 into biodegradable plastic precursors.

Understanding Direct Ocean Capture

Direct Ocean Capture is a process that involves extracting dissolved carbon dioxide directly from seawater. This innovative approach holds promise for addressing ocean acidification and utilizing CO2 sustainably. The process primarily relies on electrochemical methods to convert dissolved carbon into a pure gas. Despite its potential, the widespread application of DOC has been limited due to high costs and technical challenges. Current estimates suggest that removing one ton of CO2 from the ocean could cost at least $373. Nevertheless, advances in this field could significantly reduce costs and enhance feasibility.

Research institutions, including the Chinese Academy of Sciences, are at the forefront of developing efficient DOC methods. Their approach aims to convert captured CO2 into biodegradable plastics, offering a dual benefit of environmental conservation and industrial utility. The key lies in optimizing the electrochemical processes to ensure energy efficiency and cost-effectiveness. As technology progresses, DOC might become a viable solution to mitigate the impacts of carbon emissions and ocean acidification.

Innovative Methods and Efficiency

Researchers have developed a DOC method that boasts an impressive 70% efficiency rate. This method requires only 3 kilowatt-hours of energy per kilogram of CO2 captured, with an estimated cost of $230 per ton. This energy-efficient approach involves a series of steps to convert seawater’s dissolved carbon into useful products. Initially, electricity is used in a reactor to acidify seawater, converting the carbon into a gas. The system then restores the water’s chemistry before returning it to the ocean.

The captured CO2 gas is further processed in a second reactor, yielding formic acid through a bismuth-based catalyst. This formic acid serves as a critical intermediate, as it is an energy-rich food source for engineered marine microbes. These microbes efficiently metabolize formic acid to produce succinic acid, a precursor for the synthesis of biodegradable plastics like polybutylene succinate (PBS). This innovative method not only addresses carbon capture but also contributes to sustainable industrial processes.

The Role of Engineered Microbes

A crucial element of this DOC method is the use of engineered marine microbes, specifically Vibrio natriegens. These microbes are fed pure formic acid as their sole carbon source, enabling them to produce succinic acid efficiently. This process exemplifies the synergy between biological and chemical engineering in addressing environmental challenges. Succinic acid, produced by the microbes, is integral to creating biodegradable plastics, thus reducing reliance on fossil fuels.

Additionally, the potential applications of this process extend beyond plastic production. With further optimization, the system could be adapted to produce chemicals for fuels, pharmaceuticals, and even food products. The versatility of the method highlights the potential for significant advancements in multiple industries, offering a sustainable alternative to traditional production methods that heavily depend on fossil resources.

Future Prospects and Commercialization Challenges

While the advancements in DOC technology are promising, several challenges remain before it can be widely commercialized. The cost of capturing CO2 from oceans needs further reduction to compete with traditional carbon capture methods. Researchers and companies are racing to achieve this, with some aiming to bring costs under $200 per ton by 2030. The competition in this niche is expected to drive innovation and efficiency improvements.

Commercializing this technology will require extensive collaboration between scientists, industry stakeholders, and policymakers. The integration of DOC methods into existing industrial processes will necessitate regulatory approvals and investment in infrastructure. As research progresses, the potential to scale these methods globally could play a significant role in reducing carbon emissions and promoting sustainable industrial practices.

The exploration of Direct Ocean Capture represents a significant stride towards addressing the dual challenges of ocean acidification and carbon emissions. By efficiently converting captured CO2 into valuable products, this technology offers hope for sustainable industrial practices. As research and development continue, the key question remains: how can these innovative methods be scaled effectively to make a tangible impact on global carbon reduction efforts?

This article is based on verified sources and supported by editorial technologies.

Did you like it? 4.5/5 (30)