The Brief

A French company produced the roof at a facility in Germany.

The 24 panels weigh about 5,000 pounds each.

The roof will be done by the end of the year and the stadium repairs will be done by April.

ST. PETERSBURG, Fla. – Friday, the 18th panel out of 24 was installed on Tropicana Field’s roof. St. Pete officials say crews are on track to finish Hurricane Milton repairs to the Trop by the Rays’ opening day in April. They say the new roof will be stronger and able to withstand 165 mph winds.

What we know

How the panels, or the membrane as crews call it, were made and how they got to Florida was an international effort. A French company, the Serge Ferrari Group, helped design it.

READ: Gibsonton woman’s viral catch at Tampa Bay Rays game earns her membership in the ‘Golden Cap Club’

“We weave with the fiberglass yarns, the membrane,” David Peragallo, the specifications manager for U.S. projects for the Serge Ferrari Group, said. “Then, we had to coat the membrane to protect it with PTFE, and then we make these jumbo rolls, so large and heavy rolls.”

The Teflon-like coating protects it. All of that was done at a facility in Germany. The Serge Ferrari Group then shipped what looked like massive spools to the fabricator in China.

“They cut, and they welded according to the engineering, according to patterns that were supplied, and once they have the final membrane divided in different sections, it is shipped to Tampa,” Peragallo said.

MORE: Hillsborough commissioners approve funding to upgrade Steinbrenner Field

“We are talking about the top product of the market right now to cover a sports venue, not only in the USA, also we have stadiums in Spain, like Atlético Madrid in Spain, the Munich Stadium, the Olympic Stadium in Germany,” he said.

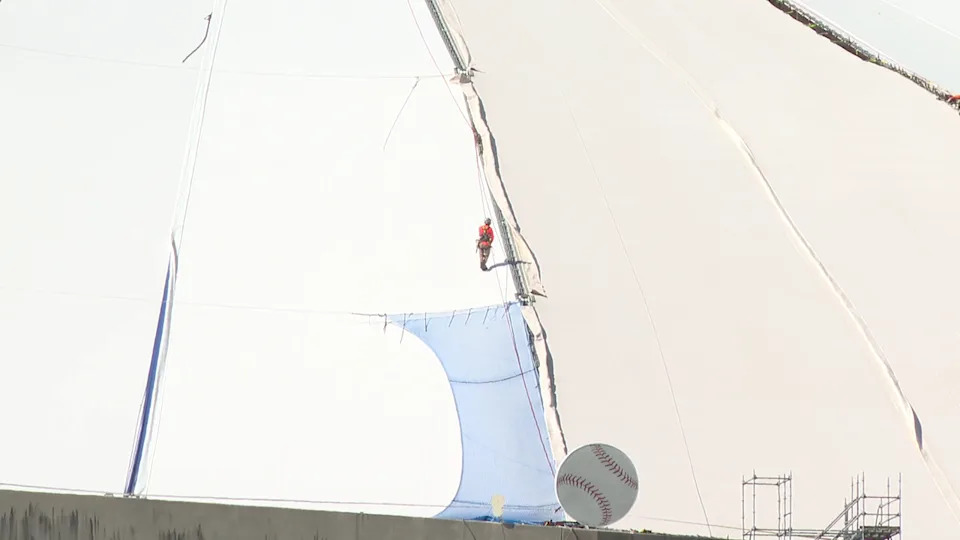

Peragallo said the panels are initially a beige color when they’re first installed and will become white due to the sun’s rays.

“The membrane will react when it will be exposed to the UV light. So, UV will affect the membrane to achieve the right color. That again, it doesn’t mean that we’re adding white pigments. It means that the membrane is becoming transparent. Of course, it’s not totally transparent, because otherwise you will have too much light and too much sun into the building. So, that final color will give you the right balance between transparency and shading,” Peragallo said.

Timeline

Peragallo said they’re used to supplying roofs for new builds, and usually have three years to design and build them. This, though, was done in about three months.

READ: New Rays ownership pledges commitment to Tampa Bay area

“This time was really challenging because there was no time … This was an emergency,” he said.

“I think it was a successful experience for us and for everybody involved, hopefully, including the city and the team, and of course, the most important, the fans,” Peragallo said. “I think everybody involved in this project … including the city and you guys who live there, should be proud of the fast reaction that everybody had.”

What they’re saying

“This is one of our largest projects in the USA, one of the most important ones,” he said.

Peragallo said the new roof should last more than 20 years. He said it would look similar to the previous one with little changes.

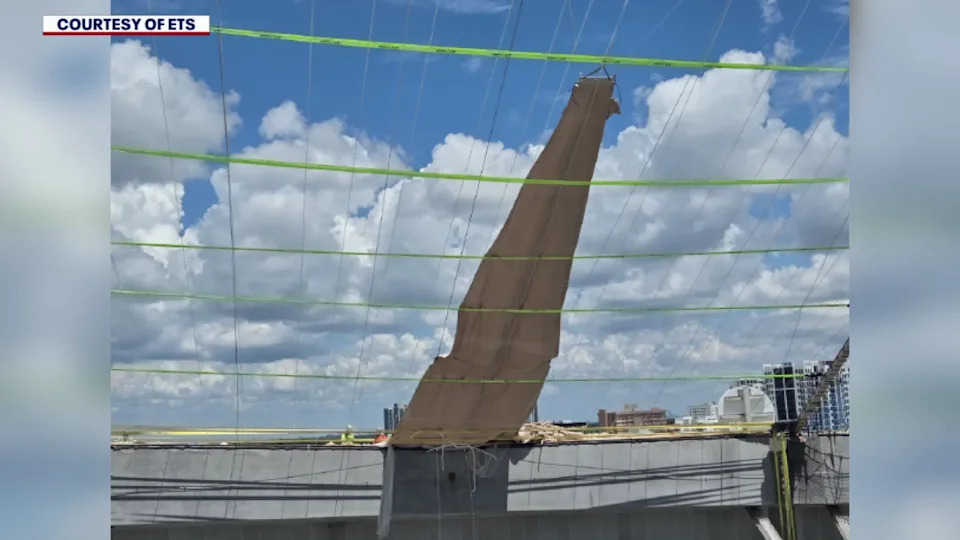

Enclos Tensile Structures, ETS, the company helping install the panels, says a few of their team members worked on the original roof design and installation too.

MORE: Local investors unveil redevelopment proposal for Gas Plant District, with or without the Rays

“It is a full-circle career moment for a few of us,” Ted Douvlos, the senior project manager for ETS, said. “That is unique.”

Dig deeper

According to Douvlos, the panels are about 5,000 pounds each and are some of the largest they’ve ever installed and in the industry. Each panel takes about six days to pull, clamp and permanently affix.

“These panels are some of the largest we’ve ever installed, requiring a larger, coordinated crew effort with extreme awareness to the surrounding environment. A turn in weather, such as a gust of wind, is something we always plan and manage for, but the scale of the sail here is among the largest we’ve handled,” he said.

Douvlos said each stadium project is different and each poses different challenges. Regarding the Trop’s roof, he said repairs and renovations are a little harder than new construction.

“New construction allows sequence and install to be more favorable to the installation of the membrane. On Tropicana, the PTFE panels are attaching to the existing structural roof, which requires thoughtful attachment planning and execution,” Douvlos said.

The accessibility to the structure also makes it difficult. They aren’t able to use boom lifts due to the structure’s design.

READ:Tampa Bay Rays sale finalized with new ownership group led by Florida-based business executive

“Typically, ETS crew members use boom lifts positioned below, on the ground or field or play, to reach the work zone on many of our projects. Because of the unique design of Tropicana’s roof structure, the access is more reliant on rope access technicians and elevated safety measures working at such great heights,” Douvlos said.

Cranes lift materials to the roof. According to Douvlos, from the cupola down to the floor is about 210 feet.

What’s next

“I would like to thank the City of St. Petersburg, Hennessey/Hunt and the Tampa Bay Rays for giving us the opportunity to work on this project, and a special thanks to my co-workers especially Allen Gadus Construction Manager, Mark Davis Director of Membrane Manufacturing and Gieger Engineers for all the hard work and assistance they continue to provide on this project,” Douvlos said.

As for Peragallo, who’s from Chile, he admits, he wasn’t a baseball fan going into the project, but he is now, specifically, a Rays fan.

“I’m quite ignorant about the sport. So, I will be more than happy to attend a game under our roof and have someone to teach me what’s going on and learning a little bit more about baseball, especially in St. Pete. I would love to do that under our roof,” Peragallo said.

The roof should be done by the end of the year and then crews can start work on other repairs. All of the repairs will cost almost $60 million. The city is legally obligated to pay for the repairs.

The Source

This story was written with information provided by ETS, the Serge Ferrari Group and the City of St. Pete.